China Auto Accessories Manufacturer, Supplier, Factory

Our Auto Accessories product molds include: Auto Accessories exterior product molds, Auto Accessories interior product molds, Auto Accessories electronic product molds, Auto Accessories beauty product molds, Auto Accessories modification product molds, Auto Accessories anti-theft product molds, Auto Accessories safety product molds, Auto Accessories component molds, etc. Efficient and high-quality, recognized by the industry.

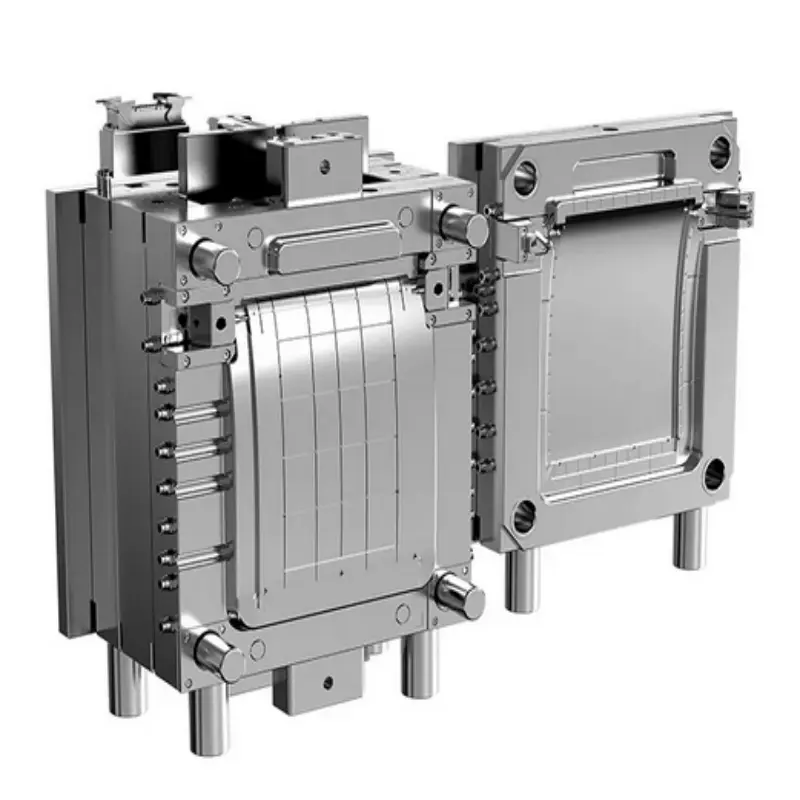

Mould for Auto Accessories supplies

If a company has good experience in making Auto Accessories product molds, it usually means that we have gone through multiple practices and improvements, and have mastered the skills and processes of making molds.

We usually have the following characteristics:

1. We have a professional team: we have experienced designers, engineers, and technicians who can design and manufacture high-quality molds according to the requirements of Auto Accessories manufacturers.

2. Advanced production equipment and technology: We have advanced production equipment and technology that can improve the production efficiency, accuracy, and lifespan of molds, and reduce costs.

3. Good after-sales service: We provide high-quality after-sales service, including mold maintenance, repair, and upgrading, to ensure the long-term stable operation of the mold.

In short, an experienced Auto Accessories product mold company usually possesses the characteristics of professionalism, advanced, and high-quality after-sales service, which can provide high-quality, efficient, and low-cost mold services for Auto Accessories manufacturers.

Our company is a company specializing in Auto Accessories product molds, which indicates that we have deep professional knowledge and experience in the Auto Accessories manufacturing industry. The following are some common Auto Accessories products for which our company has made molds:

1. Auto Accessories components: such as headlights, doors, seats, steering wheels, wipers, etc., all of which require molds for production.

2. Auto Accessories interior and exterior decorations: such as car logos, door handles, wheels, exhaust systems, etc.

3. Auto Accessories electronics: such as car dashboard, central control display screen, etc.

4. Car beauty products: such as car mats, seat covers, steering wheel covers, etc.

5. Auto Accessories maintenance tools: such as various wrenches, screwdrivers, etc., which also require molds for production.

6. Car decorations: such as car curtains, car carpets, etc.

These are just a few common Auto Accessories products. In fact, the Auto Accessories manufacturing industry involves a wide variety of Auto Accessories products. Our company can customize molds and produce various types of Auto Accessories products according to customer needs.

Mold making refers to the use of metal materials to process and manufacture tools with a certain shape and size based on the design drawings of the product, which are used to produce products of the same shape and size.

The steps for making Auto Accessories product molds are as follows:

1. Design mold: Design the mold according to the product design drawings and requirements, including the structure, size, and processing technology of the mold, to ensure that the mold can meet the production requirements of the product.

2. Material selection: According to the specific requirements of the mold, select suitable metal materials for mold production, commonly used materials include steel, aluminum, etc.

3. Processing molds: Using mechanical processing equipment such as milling machines, drilling machines, lathes, etc., to process the selected materials and manufacture mold components with a certain shape and size according to design requirements.

4. Assembly of molds: Assemble the processed mold components to form a complete mold structure.

5. Debugging the mold: Conduct debugging on the assembled mold, check the accuracy and feasibility of the mold, and ensure that the mold can work normally.

6. Inspection of molds: Conduct strict inspections on the debugged molds, including shape, size, quality, and other aspects.

7. Use of molds: Qualified molds can be put into use for the production of Auto Accessories exterior products.

In summary, the production of Auto Accessories exterior product molds involves a series of processes such as design, material selection, processing, assembly, debugging, and inspection to produce molds suitable for the production of Auto Accessories exterior products, in order to meet market demand.

Auto Accessories exterior product mold is a type of mold used for manufacturing Auto Accessories exterior products, typically used to produce components such as car lights, wheel covers, door guards, door handles, luggage racks, etc. These molds are usually designed and manufactured by professional mold manufacturing companies, using high-precision machine tools and advanced processing technology to ensure that the produced Auto Accessories exterior products meet the quality standards of Auto Accessories manufacturers.

The design and manufacturing of Auto Accessories exterior product molds involve multiple professional fields, including machinery, plastics, molds, etc. Mold manufacturing companies usually design, manufacture, test, and repair molds according to the requirements of automobile manufacturers to ensure that the produced Auto Accessories exterior products meet specifications and quality standards.

In the design and manufacturing process of Auto Accessories exterior product molds, it is necessary to pay attention to many factors, including mold material, accuracy, lifespan, cost, etc. In addition, it is also necessary to consider the production efficiency, safety, and environmental friendliness of the mold to ensure that it can meet the production needs of Auto Accessories manufacturers.

Mould Time:20-35 Days

Product time:7-15 Days

Moud precision;+/-0.01mm

Mould life;50-100 million shots

Mould cavity;One cavity, multi-cavity or same different products be made together

Mould material:P20,2738,2344,718,S136,8407,NAK80,SKD61,H13

Runner system:Hot runner and cold runner

Base material:P20,2738,2344,718,S136,8407,NAK80,SKD61,H13

Finish:Pitting the word, mirror finish, matte surface, striae

Standard:HASCO, DME or dependent upon

Main technology:Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Software:CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances)

Product material:ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,T PR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS.

Quality system:ISO9001:2008

Establish time:20days

Equipment:CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suit case mould zhejiang

We are committed to producing high-quality molds and providing the best service at the best price. You can provide us with pictures and dimensions of the products you want to make, we will design drawings and make molds for you, and hope to become a long-term partner with you.

P&M Mould Plastic adhere to the development and manufacturing guidance of "high speed, accuracy, efficiency, environmental protection, and low consumption" to improve production efficiency, reduce costs, and create economic benefits and value for customers.

Automobile Supplies mould Warmly welcome contact me at any time.

- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

- View as

Car Luggage Rack Molding

Ningbo (P&M) Plastic and Metal Products Co., Ltd. has rich experience and professional knowledge in customizing luggage rack molding. Our team is committed to providing customers with high-quality, customized luggage rack molding solutions to meet various needs and design requirements.

Read MoreSend InquiryThreshold Molding

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and threshold moulding . We have our own engineer and factory, so that we can customer any plastic and metal products for our customer.

Read MoreSend InquiryCar Stereo Molding

Ningbo (P&M) Plastic and Metal Products Co., Ltd. has rich experience and professional knowledge in customizing car stereo molding. Our team is committed to providing customers with high-quality, customized car stereo molding solutions to meet various needs and design requirements.

Read MoreSend InquiryHumidifier Molding

Our company focuses on the research and manufacturing of customized humidifier molding. Proficient in aerodynamic optimization to ensure that the tail design meets the stability and aesthetic requirements of vehicles during high-speed driving.Using 3D modeling and CAE analysis to optimize streamlined design, reduce wind resistance, and improve vehicle handling performance.Support OEM and customization in the modification market, providing a one-stop solution from conceptual design to humidifier molding manufacturing.

Read MoreSend InquirySeat Cover Moulding

For seat cover moulding, Our company has many years of industry experience in the design and manufacturing of seat cover moulding, and is committed to providing customers with high-precision and high seat cover moulding solutions. With advanced production equipment, professional engineering team, and strict quality control system, we have provided customized seat cover moulding for numerous domestic and foreign customers, widely used in household, industrial, automotive repair, outdoor storage and other fields.

Read MoreSend InquiryCushion Moulding

Ningbo P&M Products Co., Ltd. is a large customized cushion moulding manufacturer and supplier in China. Our team is committed to providing customers with high-quality, customized cushion moulding solutions to meet various needs and design requirements. Through years of practical experience, we continuously optimize and improve our manufacturing processes to ensure the production of precise and durable products that meet customer expectations.

Read MoreSend Inquiry