- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

China Custom Mold Manufacturer, Supplier, Factory

Custom molds include injection molds, blow molds, die casting molds and rotational molds. We have unique insights into the production of these similar molds.

Injection mold:

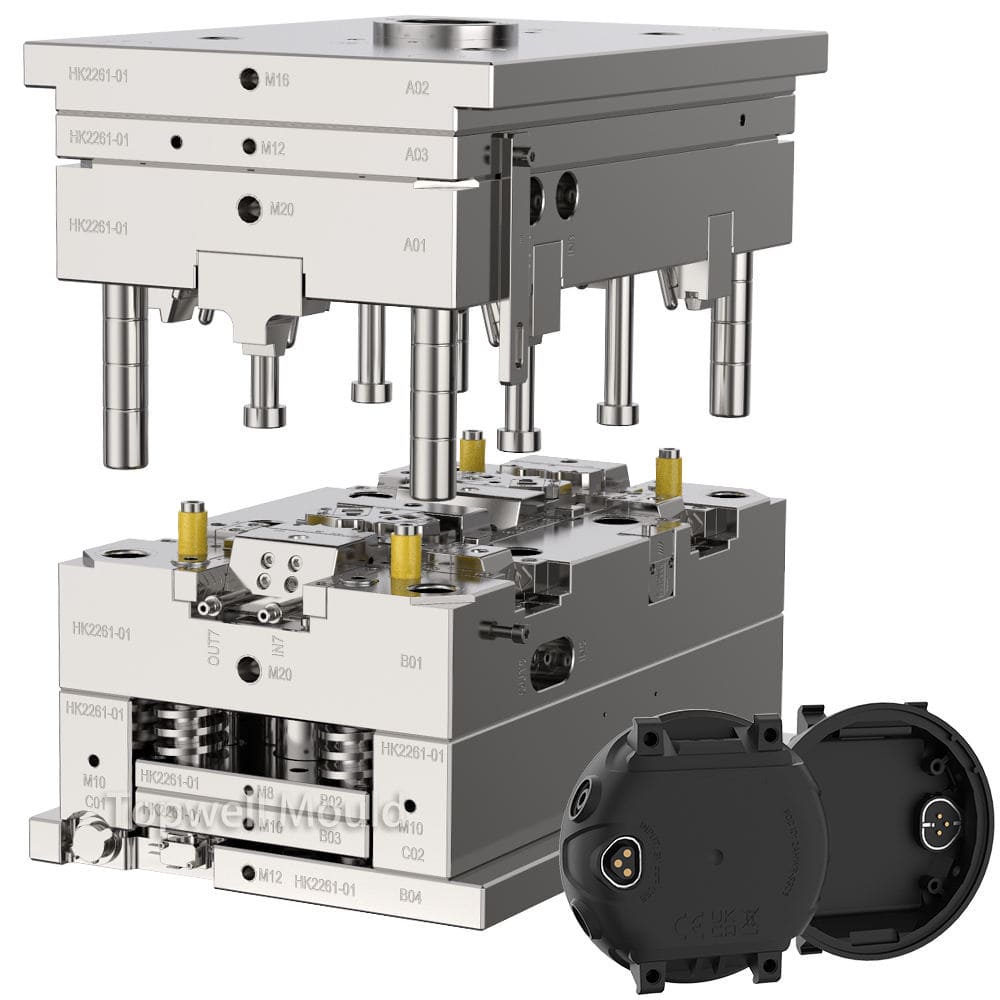

Injection mold is a tool that injects molten plastic into a precision cavity under high pressure and obtains a product of a specific shape after cooling and shaping.

Design stage:

1. Intelligent design system

AI-assisted topology optimization: input product load (such as automotive parts need to withstand 2000N impact force) to generate lightweight reinforcement rib layout (weight reduction of 20%-30%).

2. Digital twin verification: simulate melt flow through Moldflow 2025 (accuracy ±0.5%) and predict sink mark location (error ≤1mm).

3. Modular architecture: standard mold frame (LKM/FUTABA) with replaceable inserts, support new mold configuration within 48 hours.

4. Core design parameters

Parting surface design: 3D curved parting (tolerance ±0.01mm)

Cooling system design: Metal 3D printing conformal water channel

Exhaust design: Porous metal inserts (air permeability 0.8L/min·cm²)

Material and manufacturing engineering:

1. High-performance Steel : P20 718 s136 H13

2. Surface strengthening technology:

Diamond-like carbon coating (DLC): Friction coefficient ≤ 0.08, demolding force reduced by 50%

Micro-arc oxidation: Generate a 50μm ceramic layer on the surface of the aluminum mold, and increase corrosion resistance by 5 times

Blow molding mold:

Blow molding mold is a special tool system that uses compressed air to blow thermoplastic plastic parisons to fit the mold cavity to form hollow products.

Type:

1. Extrusion blow molding mold: split structure + double lip cooling water channel.

2. Injection blow molding mold: three-station rotary system (injection → blow molding → demolding)

3. Stretch blow molding mold: bidirectional stretching mechanism (longitudinal/radial stretching ratio 4:1)

Air pressure adaptive system:

Stage 1 (pre-blowing): 0.5-0.8MPa → control the initial expansion of the parison

Stage 2 (main blowing): 1.2-2.5MPa → precise fit to the mold cavity

Stage 3 (pressure holding): 0.3-0.5MPa → compensation for shrinkage (fluctuation ≤±0.05MPa)

Die-casting mold:

Die-casting mold is a tool system that injects molten metal into a precision cavity under high pressure (usually 50-150MPa) and quickly cools and forms complex metal parts.

Modular intelligent structure:

1. Casting system: nano-coated diverter cone (friction coefficient ≤ 0.05). The metal liquid flow rate deviation is ≤ 2%, and the filling time is shortened by 30%

2. Cooling system: 3D printed conformal water channel + semiconductor thermoelectric module (TEC). The temperature difference of the mold surface is ≤ 3℃, and the service life is extended to 800,000 molds

3. Ejection mechanism: magnetic suspension multi-directional ejection system. Synchronous accuracy ±0.01mm, die-stuck rate reduced by 90%

Innovation in die steel:

1.HOTVAR steel: temperature resistance 650℃, thermal fatigue resistance increased by 3 times (suitable for magnesium alloy die casting)

2.EcoDie 650: contains 40% recycled steel, carbon footprint reduced by 55%

Surface treatment technology:

1. Gradient coating: CrAlN/TiSiN composite coating (hardness HV 3200, corrosion resistance grade ASTM B117≥1000h)

2. Self-repairing coating: microencapsulated lubricant automatically fills microcracks, friction coefficient fluctuation ≤5%

Rotational mold:

Rotational mold is a process system that evenly applies powdered/liquid plastic to the inner wall of the mold cavity through biaxial rotation, and forms hollow products through heating and cooling

Mold structure:

1. Mold cavity design: bionic honeycomb structure (30% lighter). Anti-deformation ability is improved to 200℃/0.1mm·m⁻¹

2. Heating system: microwave resonant cavity + infrared temperature measurement closed-loop control. Temperature uniformity ±2℃, heating efficiency increased by 50%

3. Cooling system: liquid CO₂ atomization cooling. Cooling rate reaches 15℃/s, warping deformation ≤0.5%

4. Demolding mechanism: magnetostrictive ejector. Synchronous accuracy ±0.05mm, life ≥ 500,000 times

Mold substrate:

1. Aluminum alloy 6061-T6 (preferred for lightweight, thermal conductivity 229W/m·K)

2. Nickel-based alloy Inconel 625 (temperature resistance 1200℃, suitable for engineering plastics)

Surface strengthening:

1.Plasma electrolytic oxidation (PEO): generates a 50μm ceramic layer, with 8 times higher wear resistance

2.Graphene composite coating: friction coefficient ≤ 0.1, demolding force reduced by 70%

- View as

Finishing Quality Mold Tooling

Ningbo (P&M) has 15 years of mold making technology for customized Mold for plastic product. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.As a professional manufacturer, we are willing to provide you with high-quality car logo injection molds. We will provide you with the best after-sales service and timely delivery. P&M Company mainly produces various types of injection molds for car logos. Welcome to contact us!

Read MoreSend InquiryLightweight Design Molds

Ningbo (P&M) has 15 years of mold making technology for customized Mold for plastic product. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.As a professional manufacturer, we are willing to provide you with high-quality car logo injection molds. We will provide you with the best after-sales service and timely delivery. P&M Company mainly produces various types of injection molds for car logos. Welcome to contact us!

Read MoreSend InquiryStructural Part Injection Molds

For Production injection mold supplier molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom divided parts box molding service, we are professional plastic divided parts box molding maker. We can use injection molding, blow molding, die casting and rotoplastic molding. We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology. As a professional manufacturer, we are willing to provide you with high-quality car logo injection molds. We will provide you with the best after-sales service and timely ......

Read MoreSend InquiryInterchangeable Core/Cavity Molds

Ningbo (P&M) has 15 years of mold making technology for customized Mold for plastic product. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.

Read MoreSend InquiryHigh-Density Cavitation Molds

Ningbo (P&M) has 15 years of mold making technology for customized Mold for plastic product. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.As a professional manufacturer, we are willing to provide you with high-quality car logo injection molds. We will provide you with the best after-sales service and timely delivery. P&M Company mainly produces various types of injection molds for car logos. Welcome to contact us!

Read MoreSend InquiryWatertight Seal Component Molds

Ningbo (P&M) has 15 years of mold making technology for customized Mold for plastic product. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.

Read MoreSend Inquiry