- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Hand Protection Tool Molding

For Hand protection tool molds, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding

Send Inquiry

In our daily lives, hand tools can be seen everywhere, from protective gloves in the hands of workers to professional protective gear for outdoor sports enthusiasts, they provide indispensable protection for our hands. Injection molds play an irreplaceable and crucial role in the production process of hand tools. From the perspective of product quality, the accuracy of injection molds directly determines the dimensional accuracy, shape accuracy, and surface smoothness of hand tools. High precision molds can ensure that every detail of hand tools is highly compatible with design requirements, providing users with a comfortable wearing experience.

P&M Hand protection tool molding Introduction

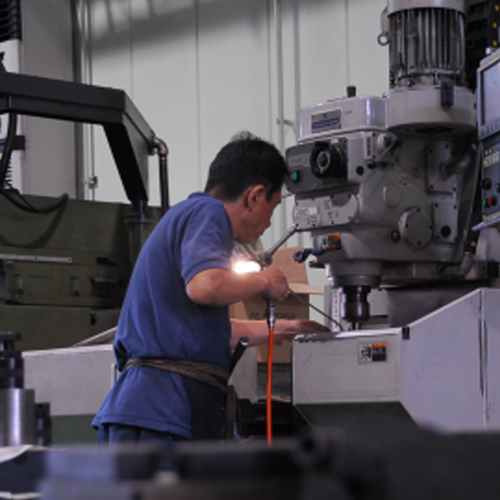

In order to ensure product quality, P&M strictly controls the production process. In the raw material procurement process, P&M has established a strict supplier screening mechanism, selecting only high-quality raw material suppliers that meet high standards. For the procurement of mold steel, P&M will conduct a comprehensive evaluation of the supplier's production process, product quality, reputation, etc., to ensure that the purchased steel has good strength, toughness, and wear resistance, ensuring the quality of the mold from the source. During the production process, P&M has established detailed quality control processes and standards, and strictly monitors and inspects each process. Using advanced testing equipment, real-time detection is carried out on key indicators such as dimensional accuracy and surface quality of molds. Once problems are found, adjustments and improvements are made immediately to ensure that each mold meets high-quality requirements.

P&M also has a unique quality management model that emphasizes full participation and continuous improvement. By conducting quality training activities, we aim to enhance employees' quality awareness and operational skills, so that every employee can deeply understand the importance of quality and consciously integrate quality concepts into their daily work.

In the high-end market, P&M has won the favor of many internationally renowned brands with its excellent quality and high-quality service. We have established long-term and stable cooperative relationships with multiple international first-line hand tool brands, providing them with customized injection mold solutions. These international brands have extremely high requirements for the quality and performance of molds, and P&M has successfully met the needs of these brands with its exquisite technology and strict quality management.

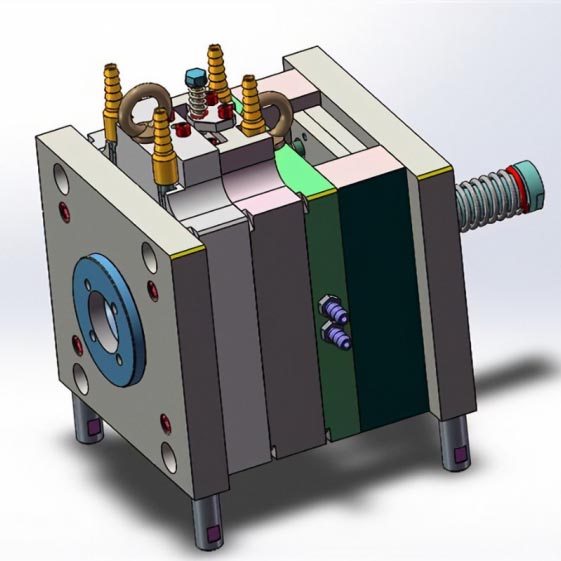

P&M Hand protection tool molding Parameter (Specification)

|

Mould Name |

Hand protection tool molding |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

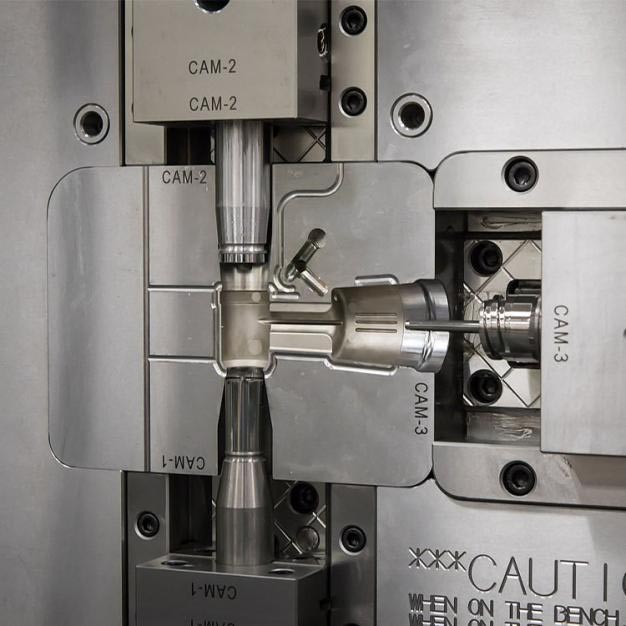

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Hand protection tool molding Feature And Application

Hand tools, as important equipment for protecting hand safety and health, have diverse functions and are widely used in various fields. In terms of functionality, hand tools first have a protective function, which is their most essential function. Anti cutting is one of the common protective functions. Anti cutting hand tools are made of special materials and designed to effectively resist cutting from knives, sharp metals, etc., protecting hands from injury. The anti slip function is also an important feature of hand tools. Anti slip hand tools can significantly increase the friction between hands and objects through special texture design or the use of anti slip materials such as rubber, silicone, etc., making the grip more stable. Hand tools have a wide range of applications. In the industrial field, it covers almost all industries. Hand tools are also widely used in daily life. The functions and applications of hand tools are closely connected, and the rich functions meet the needs of different fields, providing comprehensive protection for people's hand safety and health. The manufacturers of injection molds for hand tools are the key link in realizing these functions and applications. They produce high-quality injection molds through exquisite technology and craftsmanship, providing a solid guarantee for the manufacturing of hand tools.

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.