- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Household Cervical And Lumbar Traction Device Molding

For custom Household cervical and lumbar traction device molds, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold making technology. What we provide is professional custom mold services, and we are a professional plastic mold manufacturer. We can use injection molding, blow molding, die casting and rotational molding. We have dozens of professional designers and engineers, we can meet your requirements technically.

Send Inquiry

At the same time, we have more than a dozen professional equipment, high-end injection molding machines of different tonnages, CNC machines, we can meet customer requirements on equipment.We mainly use injection molds, die casting molds and extrusion molds to produce Household cervical and lumbar traction device. We have enough experience and technology.

We are a large-volume plastic mold manufacturer. We can customize all plastic parts of the injection mold for Household cervical and lumbar traction devices. Most of these plastic parts are made using injection molding. For example, housings, buttons, screens, etc. are almost all completed through custom injection molding services. We have made many such product shells. The key is the sealing between parts and the comfort of product design.

In terms of materials for Household cervical and lumbar traction devices, the material requirements need to be flame retardant materials because the product is related to electricity. We can provide V0 grade flame retardant ABS, PBT, PP and other raw materials. For the screen of the blood pressure monitor, optical material PC/PMMA is used. At the same time, antioxidants should be added to prevent the material from oxidizing and yellowing. At the same time, for these screen lenses, the surface needs to be coated to prevent surface scratches. In short, as long as you want the material, we can provide it. We have a variety of raw material suppliers and can provide raw materials of any brand and model.If customers have special requirements for modified materials, we can also do it, such as PLA materials, we can do it, but different modified materials correspond to different mold requirements. But we have enough experience and technology to support it.

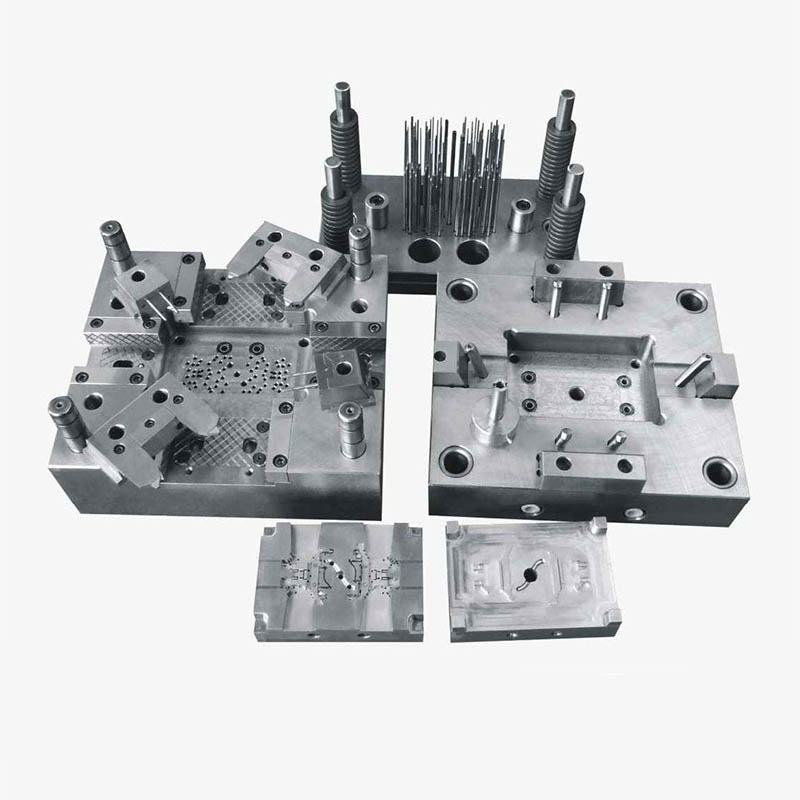

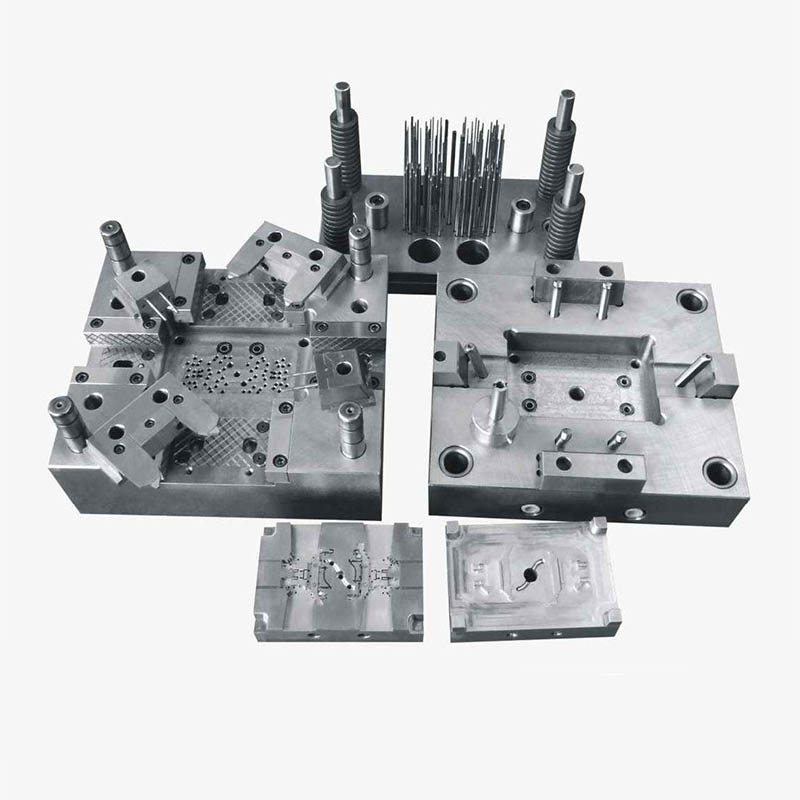

In terms of molds, the Household cervical and lumbar traction device is mainly composed of a plastic shell and a lens screen. The plastic shell can be made of 45#, p20, 718, 718H, S316, and H13. The mold can be selected according to the customer's requirements for product life. For the screen lens, the minimum requirement for the mold material is 718 mold material, and S136 mold material is generally selected. Only this material can make the screen lens achieve the effect of mirror light. We are experienced in this regard and have made hundreds of lenses with different requirements, which can meet the requirements of customers.

We can also make the corresponding metal parts of the Household cervical and lumbar traction device. This depends on the size and structure. We can use injection molding, die casting and extrusion molds to make it. Injection molds are formed by liquid aluminum inside the mold, and die casting molds are extruded by plates to the desired structure and shape. Extrusion molds are a way to extrude metal raw materials into plates. These three methods have different molding methods and each has its own characteristics.

For Household cervical and lumbar traction device products, they will also be used together with foaming molds. Foaming is done by putting plastic parts into the foaming mold and then forming them. Such sponges can perfectly wrap the plastic parts, thus meeting customer requirements

We can produce in both ways. We will give different quotation sheets for different production plans, let customers choose, and explain the advantages and disadvantages of the two methods. We are very experienced and have produced many similar products.

Household cervical and lumbar traction device mold

We are a Household cervical and lumbar traction device mold manufacturer. We provide high-quality Household cervical and lumbar traction device mold manufacturing. As long as you want to customize/develop Household cervical and lumbar traction device equipment products, you can find us. We have professional injection mold design and mature manufacturing technology. We will provide you with one-stop service, from product design-mold making-product production-product packaging-product transportation. We can help you at every stage. As long as you ask us, we will provide you with the ultimate service to make you satisfied in terms of product quality, production time, information dialogue, etc.

We are committed to producing high-quality molds and providing the best service at the best price. You can provide us with pictures and sizes of the products you want to make, and we will design drawings and make molds for you. We hope to become a long-term partner with you. If you have any needs, please contact us.

|

Product Name |

Household cervical and lumbar traction device molding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.