Patent Dispute Highlights Global Challenges and Innovation Trends

2025-06-17

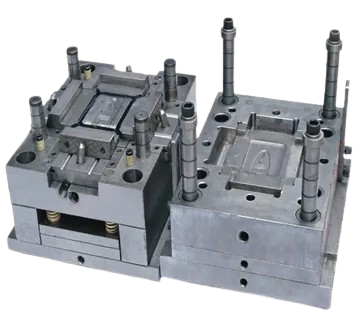

In the rapidly evolving landscape of the global plastic injection molding industry, recent legal developments and technological advancements are reshaping the competitive dynamics and sustainability goals. A high-profile patent infringement case, coupled with growing environmental regulations and digitalization efforts, is drawing attention to both challenges and opportunities within the sector.337 Investigation Sparks International Attention

In November 2024, Husky Injection Molding Systems Ltd. and Husky Injection Molding Systems, Inc. filed a complaint under Section 337 of the U.S. Tariff Act of 1930 with the U.S. International Trade Commission (ITC). The complaint alleged that certain injection molding machine components and related products imported into the U.S., including those from a Chinese enterprise, infringed upon their patents. The request for a 337 investigation aimed to impose a limited exclusion order and cease-and-desist orders. This case underscores the escalating tensions over intellectual property protection in the manufacturing sector, particularly as global supply chains intertwine.Implications for Industry Players

The Husky case has ripple effects across the industry. For Chinese manufacturers, it reinforces the urgency to strengthen IP compliance and R&D strategies to avoid trade barriers. U.S. importers face potential supply disruptions if exclusion orders are enforced, highlighting the need for diversified sourcing. Meanwhile, global industry giants are likely to increase patent monitoring and licensing agreements to safeguard their innovations. Legal experts predict that similar disputes may rise as companies seek to protect proprietary technologies in competitive markets.Sustainability Gains Momentum

Parallel to the IP debate, environmental pressures are driving significant changes. As governments worldwide enhance plastic waste regulations and carbon emission targets, injection molding companies are accelerating adoption of eco-friendly materials and processes. Biodegradable polymers, recycled resins, and energy-efficient molding machines are becoming mainstream. For example, European manufacturers are leading in integrating circular economy principles, with initiatives to reuse up to 50% recycled plastics in production. This shift not only meets regulatory demands but also attracts consumers prioritizing sustainability.Digitalization Revolutionizes Efficiency

Technological innovation is another key trend. Industry 4.0 technologies—such as IoT-enabled molding machines, AI-driven quality control, and digital twins—are optimizing production workflows. Real-time data analytics help predict maintenance needs, reduce material waste, and enhance product consistency. Major players like Arburg and Engel are investing heavily in smart factories, enabling customizable, on-demand manufacturing. SMEs, however, face challenges in adopting these costly systems, widening the technological gap.Market Growth and Regional Dynamics

Despite uncertainties, the global injection molding market is projected to grow at a CAGR of 5.2% through 2030, driven by automotive, packaging, and medical sectors. Asia-Pacific remains the largest market, with China leading in production volume. However, North America and Europe are emerging as hubs for high-tech molding solutions. Post-pandemic recovery has spurred demand for local production, reshaping supply chain strategies.Expert Insights and Future Outlook

Industry analysts emphasize that balancing innovation protection and collaboration will be critical. "Companies must navigate the fine line between guarding IP and fostering cross-border partnerships," says a consultant from KPMG. "Sustainability and digitalization are no longer optional; they are survival strategies." Looking ahead, the sector faces intertwined challenges: managing rising raw material costs, attracting skilled labor for advanced technologies, and adapting to evolving consumer demands.As the Husky investigation progresses, the injection molding industry stands at a crossroads—where legal battles, green transitions, and digital revolutions converge. Adaptability and forward-thinking strategies will determine which players emerge as leaders in this dynamic global ecosystem.