- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

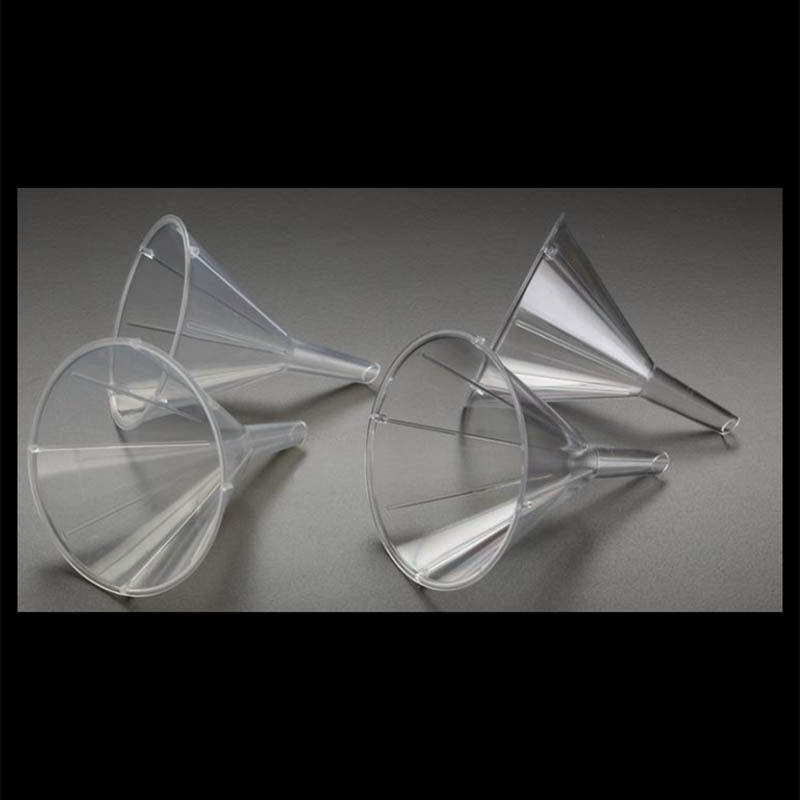

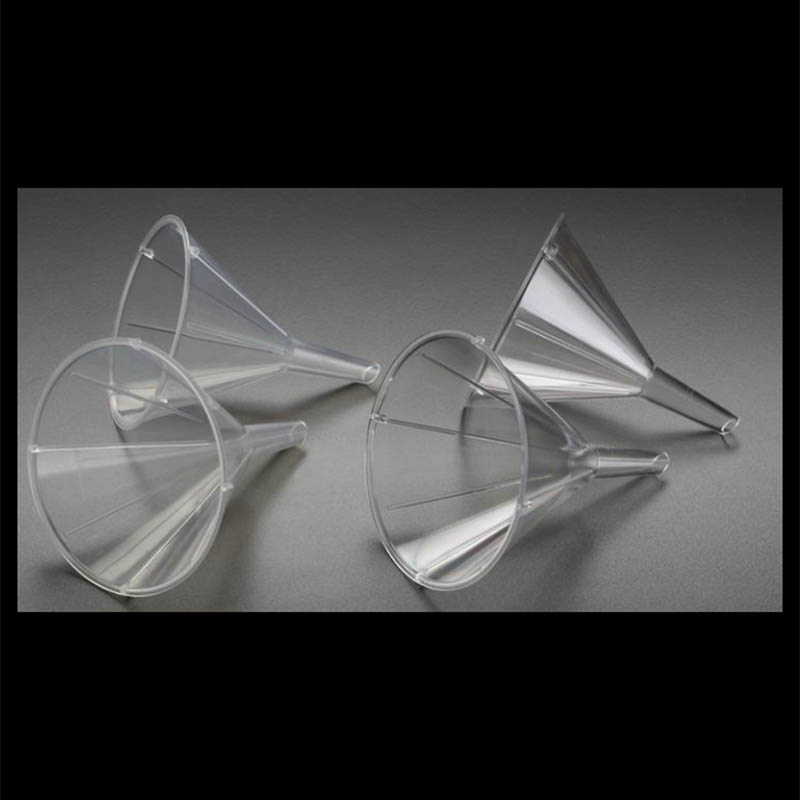

Plastic Funnels Molding

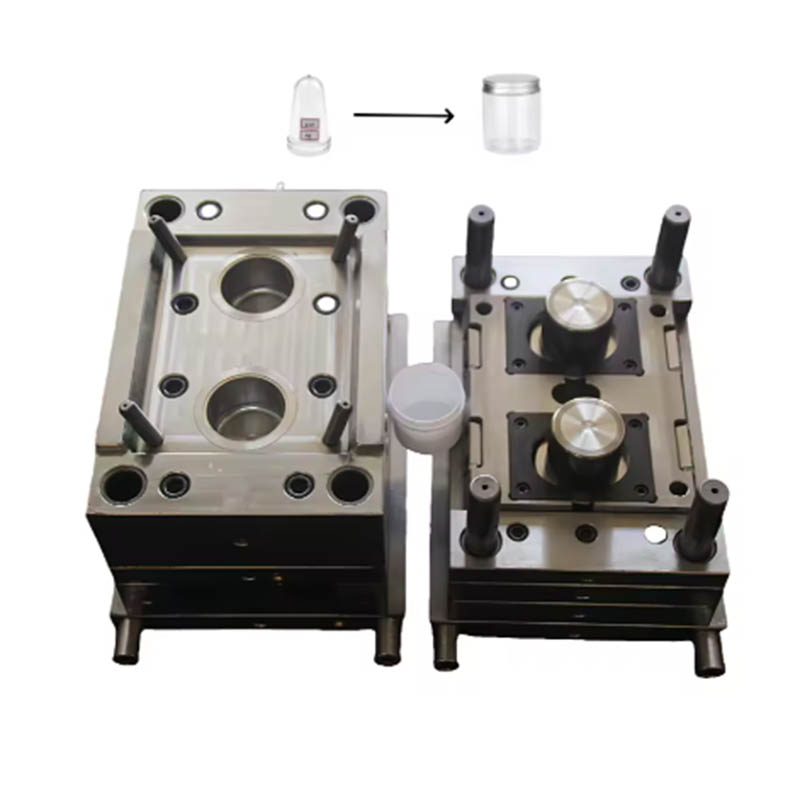

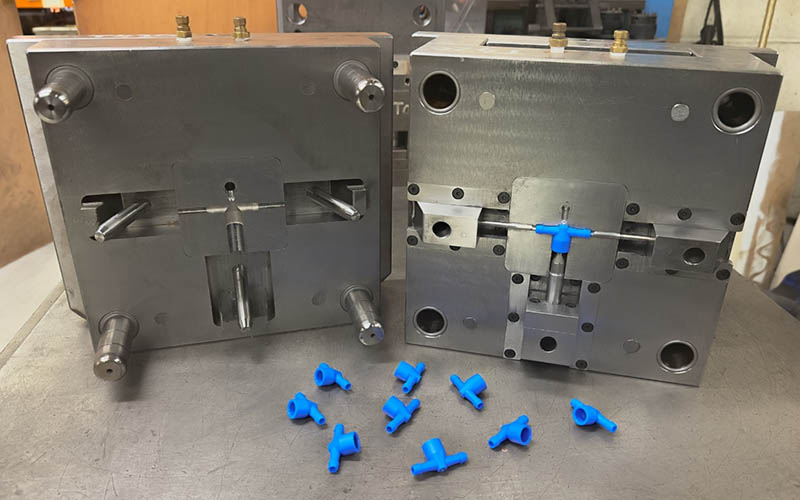

Ningbo P&M specializes in the manufacturing of Plastic funnels and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic funnel solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic funnels sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic funnels. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.

Send Inquiry

Types and Applications of Plastic Funnels

Plastic funnels are essential tools used for transferring liquids, powders, and other substances with precision and ease in various settings, including laboratories, kitchens, workshops, and more. They come in different types and designs, each tailored for specific applications based on their features and characteristics. Let's explore the types, applications, and significance of plastic funnels, followed by an overview of Ningbo P&M's strengths and advantages in injection molding plastic funnels.

Types of Plastic Funnels:

1.Standard Plastic Funnels: Conical funnels with a simple design for general liquid transfer applications.

2.Long-Stem Plastic Funnels: Funnels with elongated stems for reaching into narrow openings or containers.

3.Filtering Plastic Funnels: Funnels equipped with filter membranes or screens for separating solids from liquids.

4.Powder Funnels: Funnels with wide openings for easy pouring of powders and granular substances.

5.Separatory Funnels: Funnels with a stopcock for separating immiscible liquids based on density.

6.Ribbed Plastic Funnels: Funnels with ribbed surfaces for improved stability and controlled flow.

7.Multi-Purpose Plastic Funnels: Versatile funnels designed for a wide range of liquid and dry material transfer tasks.

8.Collapsible Plastic Funnels: Funnels that can be collapsed for compact storage and portability.

9.Chemically Resistant Plastic Funnels: Funnels made from chemical-resistant materials for handling corrosive substances.

10.Anti-Static Plastic Funnels: Funnels designed to prevent static electricity buildup during material transfer.

Applications of Plastic Funnels:

● Laboratory Experiments: Used for transferring chemicals, reagents, and samples in scientific research and experiments.

● Kitchen and Cooking: Essential for pouring liquids, oils, and dry ingredients in food preparation and cooking.

● Automotive Maintenance: Utilized for pouring fluids such as oil, coolant, and additives in vehicle maintenance.

● Arts and Crafts: Commonly used for transferring paints, glues, and other craft materials in art projects.

● Household Chores: Ideal for decanting liquids, cleaning solutions, and detergents during household tasks.

● Industrial Processes: Employed in industrial settings for transferring materials, lubricants, and chemicals.

● Pharmaceutical Applications: Used for precision pouring and transferring of medications and pharmaceutical ingredients.

● Horticulture and Gardening: Essential for pouring fertilizers, pesticides, and other garden care products.

● Cosmetic and Beauty Industry: Utilized for transferring liquids and ingredients in the production of cosmetics and personal care products.

● Educational Demonstrations: Commonly used in educational settings for demonstrating principles of liquid displacement and gravity.

Ningbo P&M's Advantages in Injection Molding Plastic Funnels:

Ningbo P&M is a prominent manufacturer specializing in injection molding and the production of high-quality plastic laboratory equipment, including plastic funnels. The company's expertise in plastic funnel manufacturing is supported by several key advantages that distinguish them in the industry.

Advantages in Plastic Funnel Manufacturing:

1.Customization Capabilities: Ningbo P&M offers extensive customization options for plastic funnels, including size, shape, design features, material selection, and color, to meet specific customer requirements.

2.Advanced Injection Molding Technology: Leveraging state-of-the-art injection molding technology, Ningbo P&M ensures the production of precise, durable, and high-performance plastic funnels with consistent quality.

3.Material Expertise: With in-depth knowledge of plastic materials and their properties, Ningbo P&M selects the most suitable materials for each plastic funnel application, considering factors such as chemical resistance, durability, and ease of cleaning.

4.Quality Assurance: Implementing rigorous quality control measures throughout the manufacturing process, Ningbo P&M guarantees that each plastic funnel meets industry standards for reliability, accuracy, and safety.

5.Cost-Effective Solutions: By optimizing production processes and efficiency, Ningbo P&M delivers cost-effective plastic funnel solutions without compromising on quality or functionality.

6.Innovative Designs: With a team of experienced engineers and designers, Ningbo P&M focuses on developing innovative plastic funnel designs that enhance functionality, usability, and performance in various applications.

In summary, Ningbo P&M's proficiency in injection molding plastic funnels, combined with their commitment to customization, quality, and innovation, positions them as a trusted supplier for industries and businesses seeking reliable and high-quality plastic funnels for a wide range of liquid and material transfer tasks.

|

Product Name |

Plastic funnels molding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products .

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.