- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

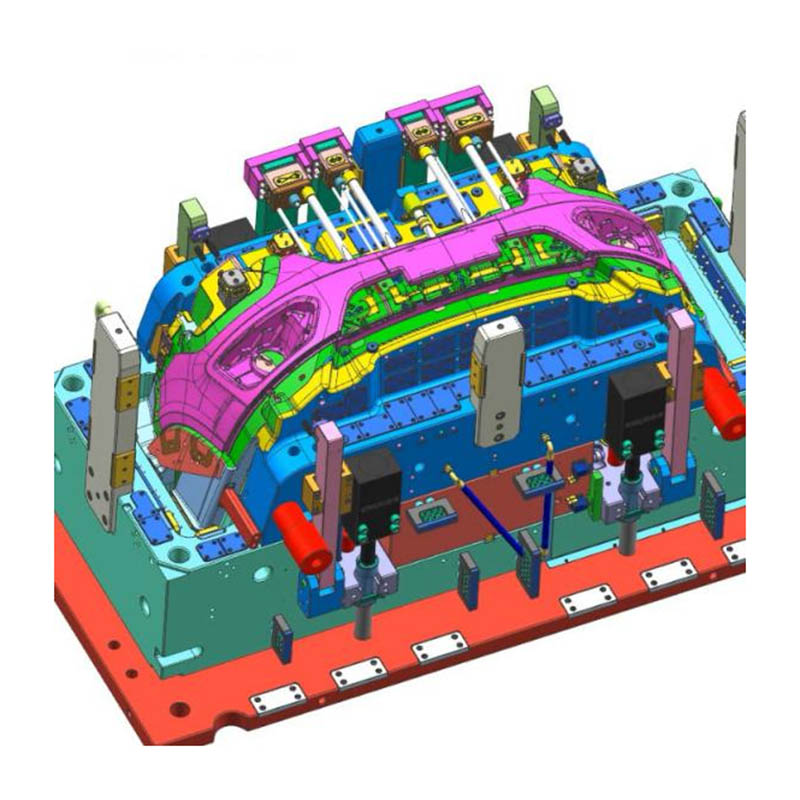

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Plastic Hair Clip Injection Mold

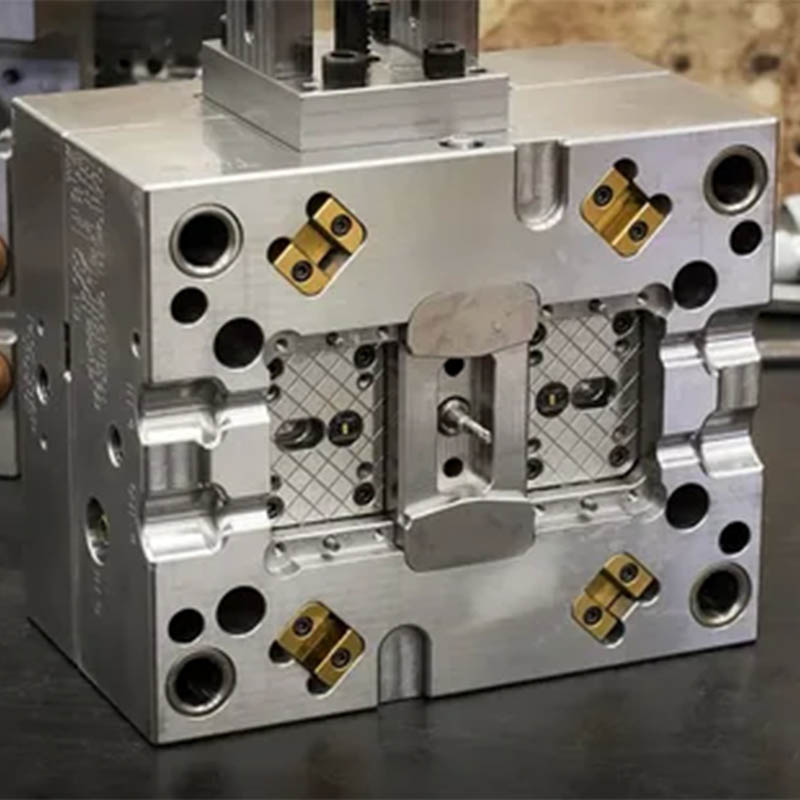

NingBo Plastic Metal Product Co.,Ltd (P&M) is a professional injection mold factory. With advanced production equipment and technical team, we are committed to providing customers with high quality plastic Hair clip injection mold.

Send Inquiry

Our factory has a wide range of experience in meeting the needs of various industries, including plastic Hair clip injection mold. We focus on quality control and use a strict testing process to ensure that each mold meets our customers' requirements. We also provide a full range of pre-sales and after-sales services, working closely with our customers to ensure they receive satisfactory solutions. Whether it is small batch or large scale production, we are able to meet customers' needs and remain competitive in the market.

Plastic Hair clip include many products. We mainly perform injection molding and production processing of these plastic parts. We usually recommend suitable plastic materials for our customers according to their needs. Raw materials like ABS/PC/PP are often used for plastic bags and storage containers. If a customer needs a higher strength plastic, we will also recommend nylon materials such as PA/PA6/PA66 for injection molding design. We always think about our customers and recommend the most suitable raw material for his products to ensure the perfect result!

Our factory focuses on quality management and adopts strict production processes and quality control measures to ensure that every injection mold produced meets high quality standards. We use high quality plastic raw materials, such as PP/ABS/PA/ etc. which are reliable raw materials and provide customized services for customers worldwide.

We can provide professional Plastic Hair clip injection mold service. Some plastic bags and storage containers we have professional mold design team, you can tell us the size you need and we can arrange the best customized service for you! We also have different mold materials for customers to choose, the mold materials reflect the mold life and product material requirements.

|

Product Name |

plastic Hair clip injection mold |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

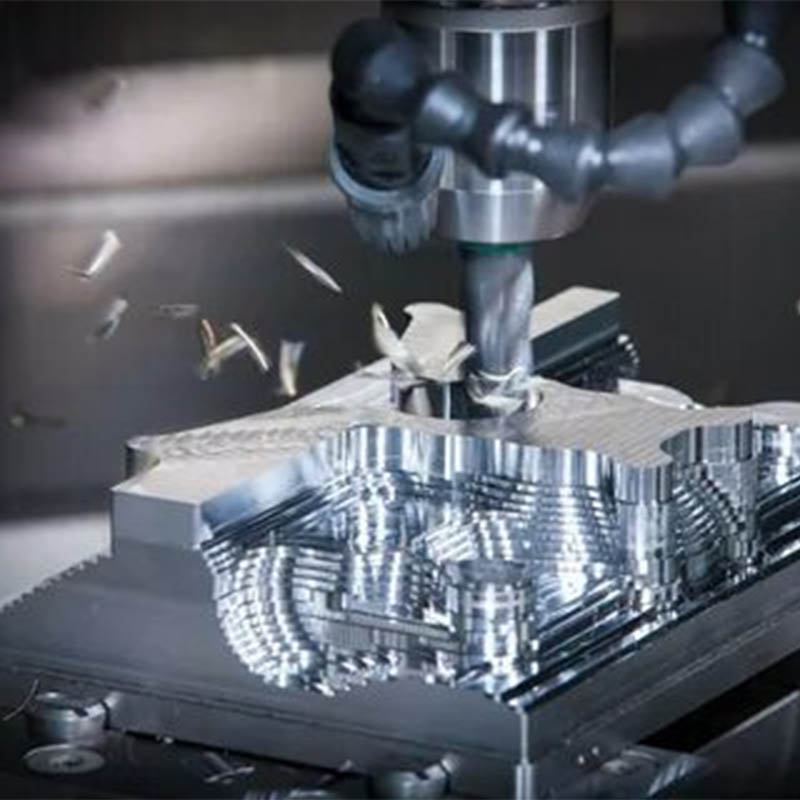

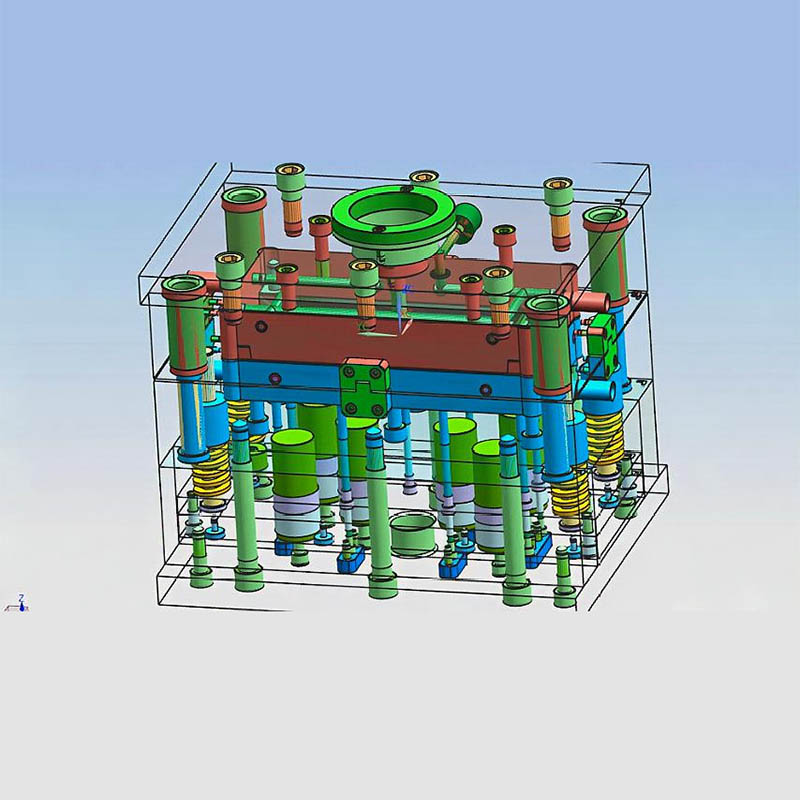

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

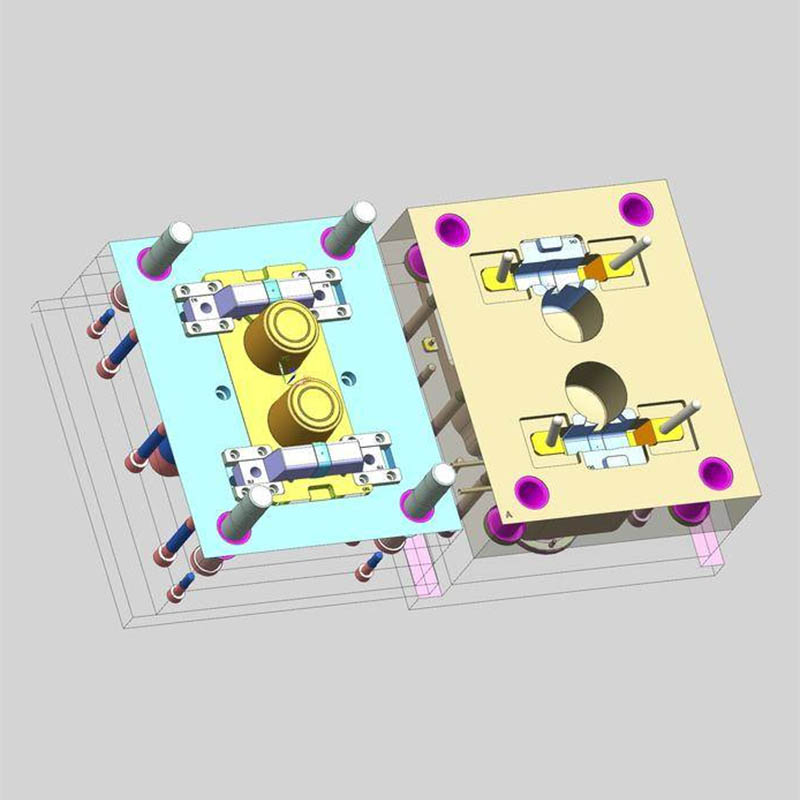

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

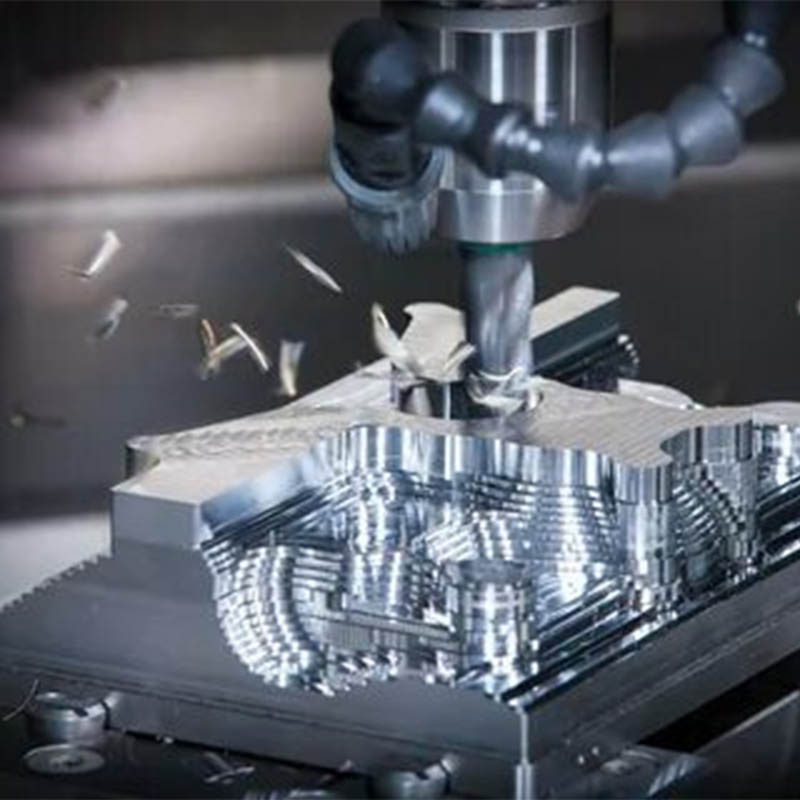

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

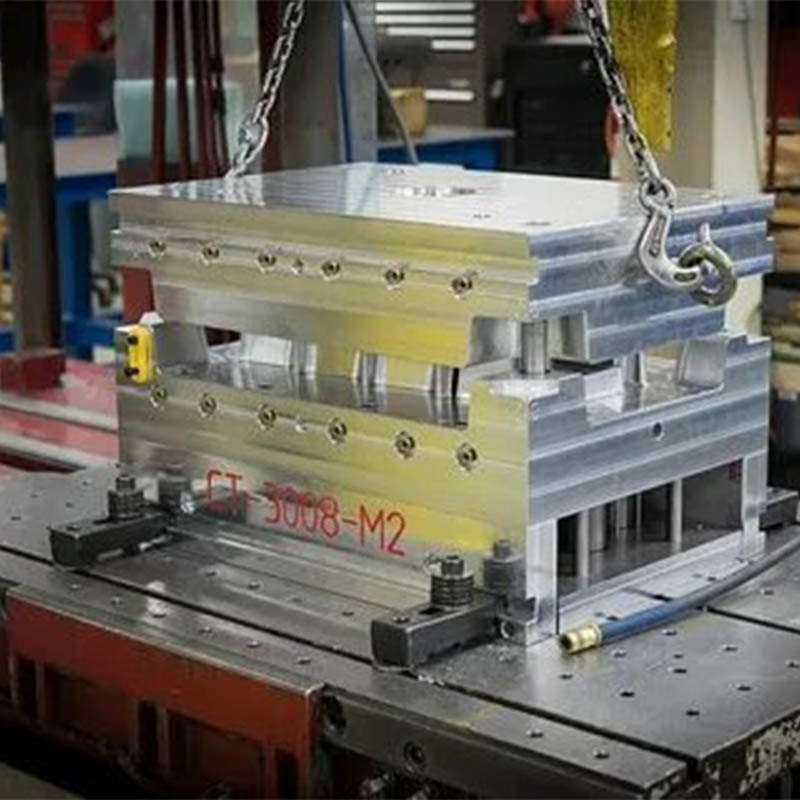

Plastic Injection Mould making

1. Samples/Drawing &Requirement from you.

2. Mould design:we will Communicate and Exchange the opinion with you after you place order.

3. Material Purchase:Steel cutting and Mould base tooling.

4. Assembling.

5. Inspection of mould : following and controlling the tooling processing.

6. Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7. Your instruction &confirmation for shipment.

8. Ready made mould before packing.

9. We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

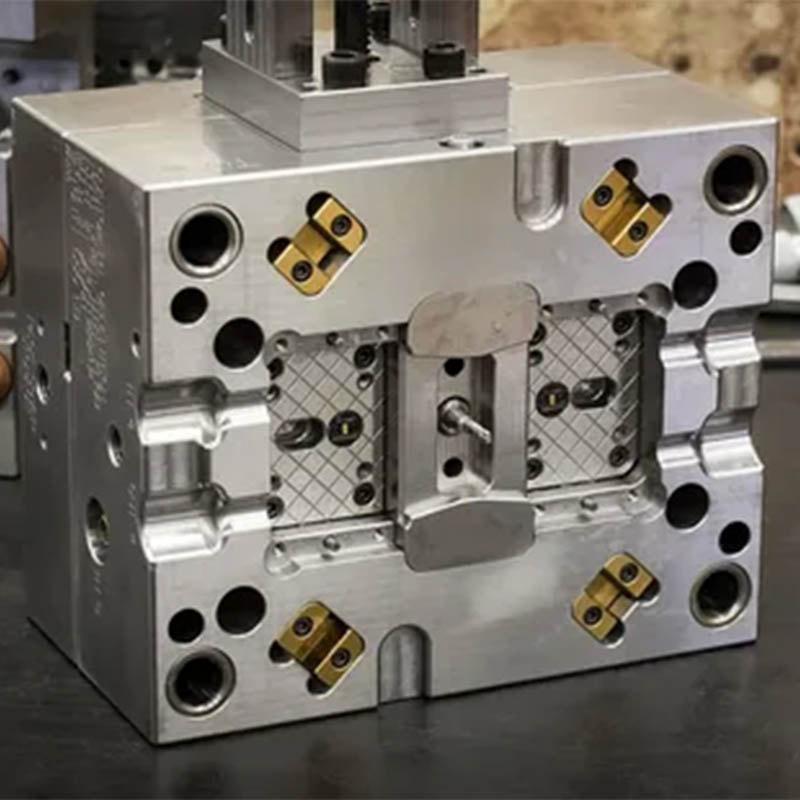

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Transaction process

Mold testing

Once the mold is complete, I do a mold test. It usually takes about 3-5 days to complete. We need to assemble the mold, adjust the pressure data of the machine, and try production. We need to check whether there are problems during the normal production of the mold and make modification.

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.