- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Archery Parts Molding

For Archery parts molds, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

Send Inquiry

In recent years, archery, an ancient and elegant sport, has ushered in a new wave of development. Whether in international events such as the Olympics, athletes' superb skills attract global attention, or in daily life, archery has gradually become a popular leisure, entertainment, and fitness choice. A high-quality bow, from the design of the bow body to the material of the bowstring, every detail is related to the archery experience and accuracy; And the arrow support, from the straightness of the arrow shaft to the sharpness of the arrow and the stability of the arrow feather, all need to be carefully crafted. The production of these equipment relies heavily on high-precision component molds. It can be said that the archery parts mold is the foundation and core of the entire archery equipment manufacturing, and its quality directly determines the quality of the final product.

P&M Archery parts molding Introduction

Design phase:

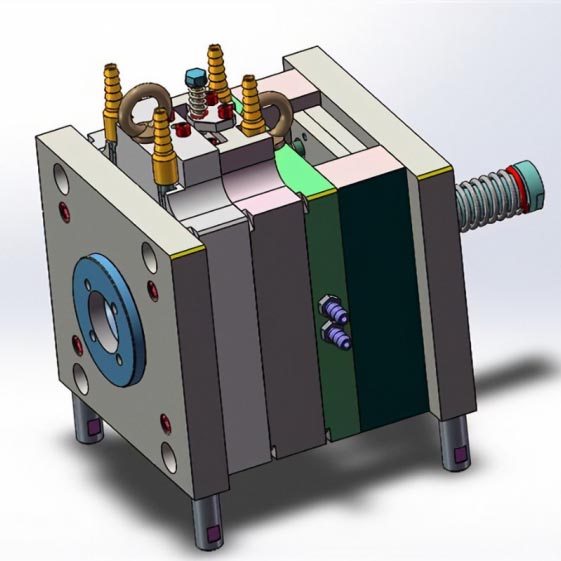

In the manufacturing of archery parts molds, the design process is undoubtedly the crucial first step, laying the foundation for subsequent production. The design team of P&M fully utilizes the principles of mechanics in mold design, conducting in-depth research on the force situation of the bow during string pulling and releasing, as well as the aerodynamic characteristics of the arrow during flight. By using computer-aided design (CAD) software, precise simulation and analysis of the bending and thickness changes of the bow arm are carried out to ensure that the bow arm can uniformly bear the force when subjected to tension, thereby improving the elasticity and stability of the bow, enabling the arrow to achieve greater initial velocity and more accurate flight trajectory. At the same time, the design team also fully considers the principles of ergonomics, focusing on the comfort and ease of operation of the shooter during use. They will design bow handle shapes and sizes that conform to human grasping habits, as well as adjustable sights and other component molds based on the physical characteristics and usage habits of different groups of people.

Material selection:

High quality materials are the key to manufacturing high-quality archery parts molds. P&M is well aware of this and strictly controls the selection of materials, striving for excellence. They also conduct strict testing on various performance indicators of materials to ensure that each batch of materials meets quality standards and guarantees the quality of molds and parts from the source. By selecting high-quality materials, P&M's archery parts molds not only have excellent performance, but also reliable quality, which can meet the needs of different customers and have won wide recognition in the market.

Processing flow: Exquisite pursuit of quality

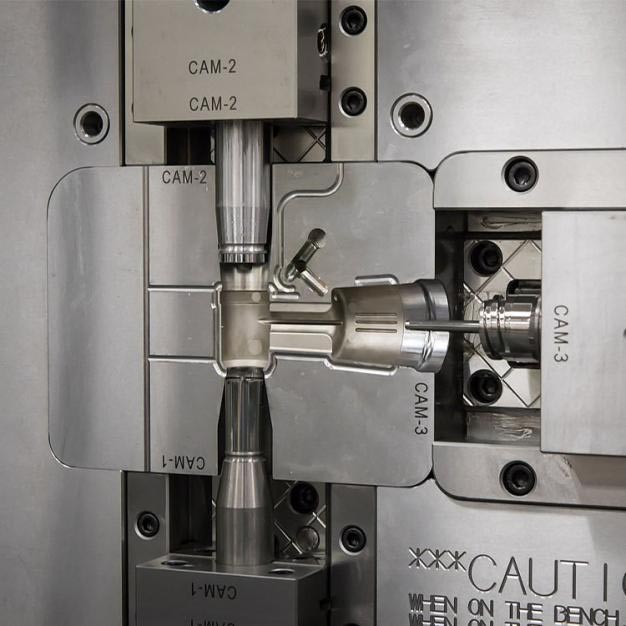

From raw materials to high-precision archery parts molds, P&M has gone through a series of complex and refined processing procedures, each of which embodies the wisdom and hard work of craftsmen, demonstrating their persistent pursuit of quality. In the cutting process, high-precision CNC cutting equipment is used to accurately cut the raw materials into the required shape and size according to the requirements of the mold design drawings. During the cutting process, strict control is exercised over parameters such as cutting speed and depth to ensure a smooth and even cutting surface with minimal dimensional errors, providing a solid foundation for subsequent processing. The precision machining process is the core of the entire machining process, using advanced CNC machining centers, electrical discharge machining equipment, etc. to perform high-precision machining on parts, achieving the complex shape and precise size requirements of molds. Numerical control machining centers can complete the machining of various complex surfaces by programming the motion trajectory of cutting tools, ensuring the accuracy and surface quality of molds. Electric discharge machining equipment utilizes the principle of discharge corrosion to process mold parts with high hardness and complex shapes, and can produce fine structures and high-precision inner holes that are difficult to achieve with traditional mechanical machining. Throughout the entire processing flow, P&M has established a strict quality control system to monitor and inspect each process in real-time. From the inspection of raw materials to the sampling inspection of semi-finished products, and then to the full inspection of finished products, every link is monitored by professional quality inspectors to ensure that every mold meets high-quality standards. Once quality issues are identified, immediate analysis and rectification will be carried out, and non-conforming products will never be allowed to flow into the next process. Through this strict quality control, P&M produces archery parts molds with high precision and stable quality, which can meet the needs of high-end archery equipment manufacturing and provide customers with reliable product guarantees.

P&M Archery parts molding Parameter (Specification)

|

Mould Name |

Archery parts molding |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Archery parts molding Feature And Application

Archery equipment is a complex and sophisticated system composed of numerous components working together, each carrying a unique function to ensure the smooth progress and excellent experience of archery.

As a key component for shooters to grip, the design of the bow handle directly affects the shooter's handling experience and stability. It not only needs to have sufficient strength to withstand the huge pulling force generated by the bow arm, but also conforms to ergonomic principles to provide a comfortable grip. Different types of bow handles are suitable for different archery styles and shooter needs.

Arrows are the key to directly hitting the target, and their quality and performance play a decisive role in the accuracy of archery. The arrow shaft requires extremely high straightness to ensure that the arrow maintains a stable trajectory during flight.

These archery parts play an indispensable role in various archery scenes. In professional competitive competitions, players have almost strict requirements for the performance and accuracy of equipment, and any small flaw in a component may affect the competition results. A high-precision bow and arrow can help athletes maintain a high shooting accuracy even at long distances, earning them honor. In leisure and entertainment archery activities, reliable equipment can allow enthusiasts to better enjoy the fun of archery, relax their body and mind, and release stress. Whether on the Olympic stage or in archery clubs in the city, these parts together embody the charm of archery and witness countless wonderful moments.

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.