- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

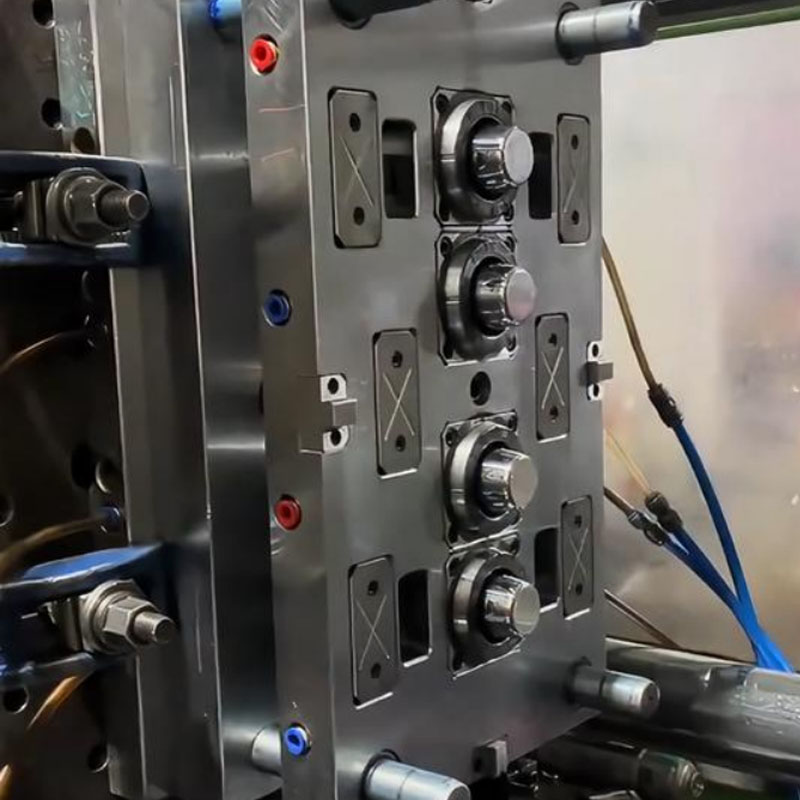

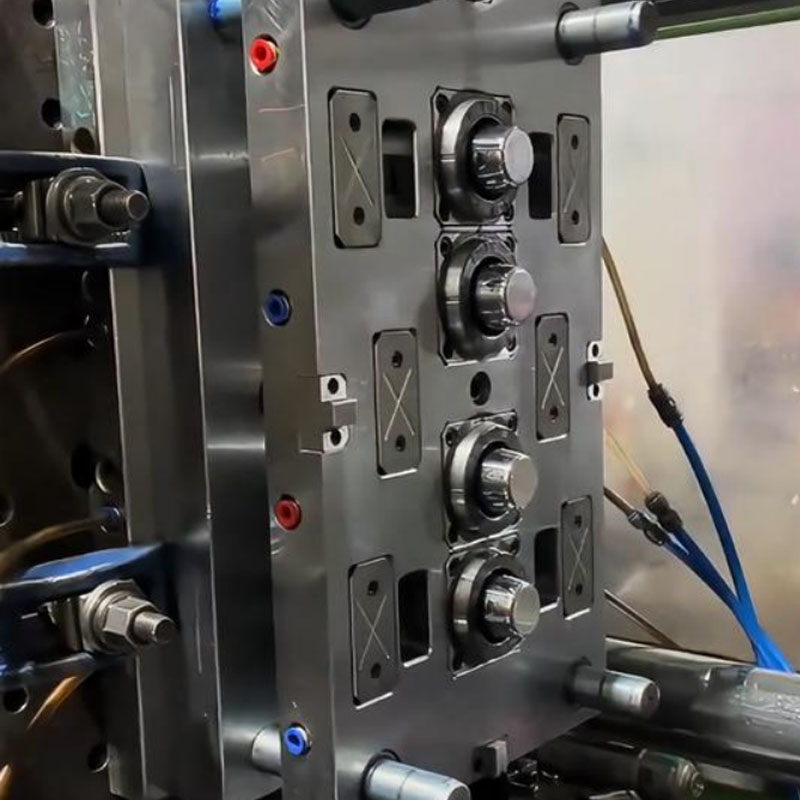

Electric Shaker Cup Moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize electric shaker cup molds. We provide professional customized electric shaker cup moulding services, and we are a professional electric shaker cup mold manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing electric shaker cup molds, our factory can provide one-stop service. We have design and production capabilities related to electric shaker cups, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies. stic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized electric shaker cup moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For electric shaker cup products, we can make corresponding plastic parts, which is mainly done through injection molds.

A detailed analysis of the design and manufacturing process of the electric shake cup injection mold (the latest practice plan in 2025), combined with the key technical features of its electric stirring, portable leak-proof, human-computer interaction and other functional characteristics:

1. Product function disassembly and mold design strategy

Core component matching and parting planning

Motor cabin integration: adopt the insert injection molding process, reserve the stainless steel motor bracket groove (tolerance ±0.05mm), and achieve seamless metal/plastic combination through in-mold hot pressing technology.

Stirring shaft positioning: design a two-way spiral glue feeding system to ensure that the coaxiality of the stirring shaft mounting hole is ≤0.03mm to avoid high-speed rotation eccentricity.

Battery compartment sealing: the parting surface avoids the charging contact area, and adopts a stepped stop structure with a silicone sealing ring groove (depth tolerance ±0.02mm).

Anti-vibration structure reinforcement

A reinforcing rib network is added to the bottom of the cup body (rib thickness 0.6-0.8mm, spacing 5mm), and the stress distribution under 3000 times/minute vibration conditions is simulated by Moldflow software.

The motor fixing point adopts a "crater" column design, and the embedded copper nut enhances the fatigue resistance of the thread (screw-in torque ≥ 2.5N·m).

Human-machine interaction interface optimization

The touch button area adopts dual-material injection molding (TPU+PC), the hard rubber layer carries the circuit, the soft rubber layer improves the touch, and the temperature difference control in the transition zone needs to be ≤8℃.

The indicator light window uses a prism texture design, and the cavity surface is treated with VDI-18 grade sun-texture, the light transmittance is increased by 40% and there is no light leakage.

2. Mold engineering deepening and processing realization

Development of special-shaped flow channel system

For the curved surface of the cup body, 3D printing conformal cooling water channel (section size Φ2.5mm±0.1mm) is used to make the mold temperature uniformity reach ±2.5℃.

The timing valve hot runner (opening and closing error <0.01s) is used in the charging port groove area to eliminate the influence of the weld line on the IPX7 waterproof level.

Dynamic core pulling technology innovation

The mixing blade storage bin is designed with a hydraulic-gear composite core pulling mechanism, with a positioning accuracy of ±0.015mm within a core pulling stroke of 35mm and a synchronization error of <0.5°.

The cup lid anti-rotation buckle adopts a nitrogen spring-driven inclined ejector structure, and the ejection speed can be adjusted to 50-200mm/s to prevent deformation of thin-walled parts.

Application of special steel

The motor contact surface uses tungsten steel inserts (hardness HRA 90) with a life of 1.5 million times; the light-transmitting area uses highly polished SUS420 stainless steel (Ra≤0.05μm).

The ejector pin is plated with diamond-like carbon coating (DLC), and the friction coefficient is reduced to 0.1, solving the problem of PLA material sticking to the mold.

3. Trial mold verification and intelligent parameter adjustment

Function coupling test

Dynamic injection molding-assembly joint adjustment: The motor is pre-installed in the mold, and the insert fit is monitored by a pressure sensor (contact resistance ≤0.1Ω).

Simulated user scenario: After the injection molding parts are installed, they run continuously for 30 minutes, and the temperature rise of the motor compartment is monitored by infrared thermal imaging ≤15℃.

Defect closed-loop correction system

Based on industrial camera + AI algorithm, the flash/sink mark is automatically identified, and the MES system is linked to adjust the pressure holding curve in reverse (response time <3 seconds).

In view of the deformation problem of the battery compartment, variable mold temperature technology is adopted (instantly heating to 130℃ and then cooling), and the flatness is improved to 0.1mm/m².

4. Intelligent upgrade plan for mass production

Digital twin factory integration

IoT sensors are installed on the mold (sampling rate 1000Hz), real-time monitoring of cavity pressure fluctuations and prediction of maintenance cycles (accuracy ≥92%).

Combined with digital thread technology, process parameters automatically match different batches of PLA materials (melting point difference compensation ±5℃).

Green manufacturing breakthrough

Bio-based PA56 material is used (carbon footprint is reduced by 60%), and a special screw combination is developed (compression ratio 2.8:1, L/D=22:1).

The waste online recycling and granulation system is integrated to achieve immediate reuse of more than 95% of scraps.

The industry has currently applied magnetic suspension mold technology on a large scale, and through active electromagnetic compensation to offset the inertial vibration of high-speed injection molding, the production cycle of electric shake cups has exceeded 25 seconds per piece, and the yield rate is stable at more than 99.3%.

We are a electric shaker cup mold manufacturer, providing high-quality electric shaker cup mold manufacturing. As long as you want to customize/develop electric shaker cup products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Shaver Moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.