- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

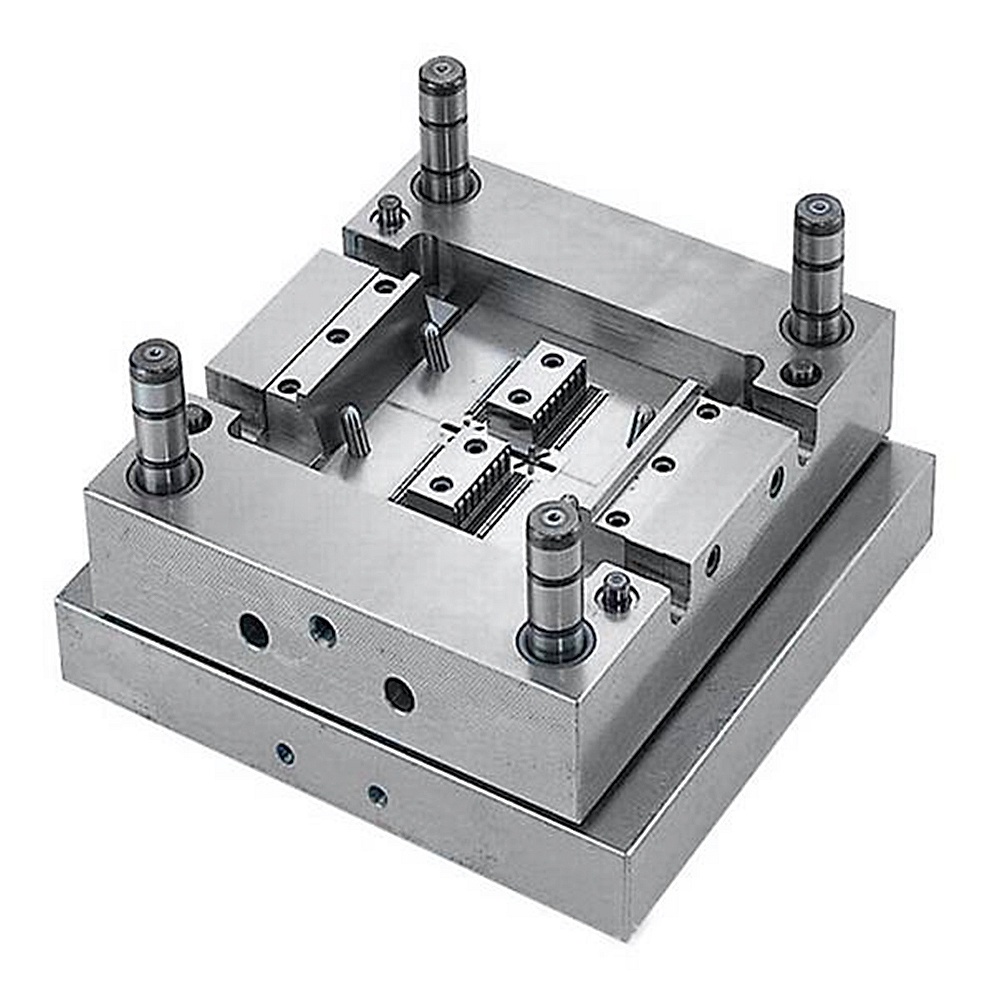

Mold for plastic seals

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Mold for plastic seals. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.

Send Inquiry

At P&M, we specialize in designing and manufacturing precision plastic seal molds that create reliable, high-performance sealing solutions. Unlike trading companies, we are your direct manufacturing partner offering complete services from custom mold design to injection molding, quality validation, and assembly. We understand that seals must perform under pressure, temperature variations, and environmental challenges. Our expertise ensures your sealing components meet exact specifications for leak prevention, durability, and performance.

Precision Mold Design for Superior Sealing Performance

Creating effective seals requires specialized mold design with exacting precision. Our molds are engineered with features specifically for sealing applications. We focus on perfecting the sealing edge geometry that determines leak prevention capability. The mold surfaces are precision polished to eliminate any microscopic imperfections that could compromise seal integrity. Our cooling systems are optimized for uniform temperature distribution to prevent warpage and ensure consistent seal dimensions. We incorporate specialized venting systems that prevent air traps in the sealing lip areas. For complex seal designs, we utilize advanced slide actions and core mechanisms that maintain perfect concentricity and cross-sectional consistency. Our mold designs accommodate various seal types including static seals, dynamic seals, face seals, and radial seals. We also design for different seal profiles such as O-rings, D-rings, lip seals, and custom geometries. Each mold is crafted with materials resistant to wear and corrosion to maintain precision over millions of cycles.

Material Selection for Optimal Sealing Performance

Choosing the right material is crucial for seal functionality and longevity. We work with an extensive range of sealing materials to match your specific application requirements. Thermoplastic Elastomers (TPE) offer excellent flexibility and compression set resistance for general purpose seals. Silicone provides superior temperature resistance and food-grade compatibility for medical and culinary applications. Fluoroelastomers (FKM) deliver exceptional chemical and high-temperature resistance for automotive and industrial uses. Polyurethane offers outstanding abrasion resistance and tensile strength for hydraulic and pneumatic applications. EPDM rubber delivers excellent weather and ozone resistance for outdoor applications. We also work with specialized materials including FFKM for extreme chemical environments, HNBR for oil and fuel resistance, and custom compounds for specific performance requirements. Our material experts consider factors such as temperature range, chemical exposure, pressure requirements, compression set, and regulatory compliance when recommending materials.

Specialized Injection Molding Process for Seals

Our injection molding process is specifically optimized for producing high-quality seals with consistent performance. We utilize scientific molding principles to establish precise process parameters that ensure repeatable results. Our machines are equipped with specialized screws and barrels designed for processing elastomeric materials. We maintain strict control over injection speeds and pressures to prevent material degradation and ensure complete cavity filling. Our temperature control systems maintain consistent material viscosity for uniform flow and packing. We implement rigorous purging procedures between material changes to prevent contamination. For multi-material seals, we employ advanced overmolding and two-shot molding techniques that create perfect bonds between materials. Our cleanroom molding capabilities ensure particle-free production for critical applications. We conduct in-process monitoring of key parameters including cavity pressure, temperature, and fill time to maintain consistent quality. Our automated handling systems prevent deformation of delicate seal geometries during post-molding operations.

Value-Added Services and Assembly Capabilities

We provide comprehensive services beyond molding to deliver complete sealing solutions. Our secondary operations include precision trimming of flash and gates using cryogenic deflashing techniques that preserve seal integrity. We offer various surface treatments including lubrication coatings for installation ease and low-friction applications. Our assembly services include mounting seals onto components, installing spring energizers, and assembling multi-part sealing systems. We provide complete testing services including pressure decay testing, helium leak testing, and functional performance testing. Our quality assurance includes 100% inspection of critical dimensions and sealing surfaces. We offer custom packaging solutions that protect seals from damage during shipping and storage. Our kitting services assemble complete sealing packages with all required components. We also provide design consultation services to optimize seal designs for manufacturability and performance. Our technical support includes failure analysis and redesign services for improved sealing solutions.

Quality Assurance and Compliance Standards

We maintain rigorous quality standards throughout our manufacturing process. Our quality system is certified to ISO 9001 standards with additional compliance capabilities for industry-specific requirements. We perform first article inspections using coordinate measuring machines for dimensional verification. Our material certification includes full traceability from raw material to finished product. We conduct regular capability studies to ensure process stability and consistency. Our testing laboratories are equipped with environmental chambers for temperature cycling tests and compression set testing equipment. We maintain documentation for all regulatory requirements including FDA, USP Class VI, UL, and RoHS compliance. Our statistical process control monitors key characteristics to prevent defects and ensure consistent quality. We provide comprehensive validation documentation for medical and automotive applications. Our quality team works directly with customers to establish appropriate acceptance criteria and inspection methods.

Industry Applications and Solutions

Our seal manufacturing expertise serves diverse industries with specific sealing requirements. Automotive applications include engine seals, transmission seals, and electrical connector seals that must withstand harsh environments. Medical device seals include syringe seals, pump seals, and implantable device seals requiring biocompatibility. Industrial equipment seals include hydraulic seals, pneumatic seals, and rotary shaft seals for heavy-duty applications. Consumer product seals include waterproof seals for electronics and appliances. Aerospace applications include environmental seals and fluid system seals meeting strict performance standards. We also serve the energy sector with seals for oil and gas equipment and renewable energy systems. Our solutions address various sealing challenges including high-pressure containment, vacuum sealing, chemical resistance, and extreme temperature performance. We understand the unique requirements of each industry and provide tailored solutions that meet both performance and regulatory needs.

Why Choose Our Seal Manufacturing Services

Our focus on sealing solutions sets us apart from general molders. We bring decades of specific experience in seal design and manufacturing. Our technical team understands the physics of sealing and can recommend optimal designs and materials. We invest in specialized equipment for seal production including cleanroom molding machines and precision measurement systems. Our quality focus ensures every seal meets performance requirements with consistent reliability. We offer flexible production capabilities from prototyping to high-volume manufacturing. Our customer service includes technical support throughout the product lifecycle from design through production. We maintain competitive pricing through efficient manufacturing processes and material optimization. Our global supply chain capabilities ensure reliable delivery wherever you need components. We protect your intellectual property with strict confidentiality agreements and secure manufacturing processes.

Start Your Seal Project Today

Beginning your custom seal project is straightforward with our expert guidance. Contact us to discuss your application requirements and performance needs. Our engineering team will provide design recommendations and material suggestions. We offer prototype development for testing and validation before production. Our quotation process includes transparent pricing and timeline information. Once approved, we manage all aspects of production through to delivery. We maintain ongoing support throughout production to address any requirements changes. Our goal is to become your long-term partner for all sealing component needs.

We are plastic mold maker and can provide custom mold service, we can make injection molds, blow molds, rotational molds and die-casting molds.

For custom injection molds, we can provide professional custom injection molding services. Usually Plastic injection mold manufacturing Molding are manufactured using injection molding technology. The mold materials for injection molds can be chosen from P20, 718, S136, H13 and so on. The mold material reflects the mold life and product material requirements.

For parts that require blow molding production, we can also provide professional custom blow molding services.

|

Product Name |

Mold for plastic seals |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

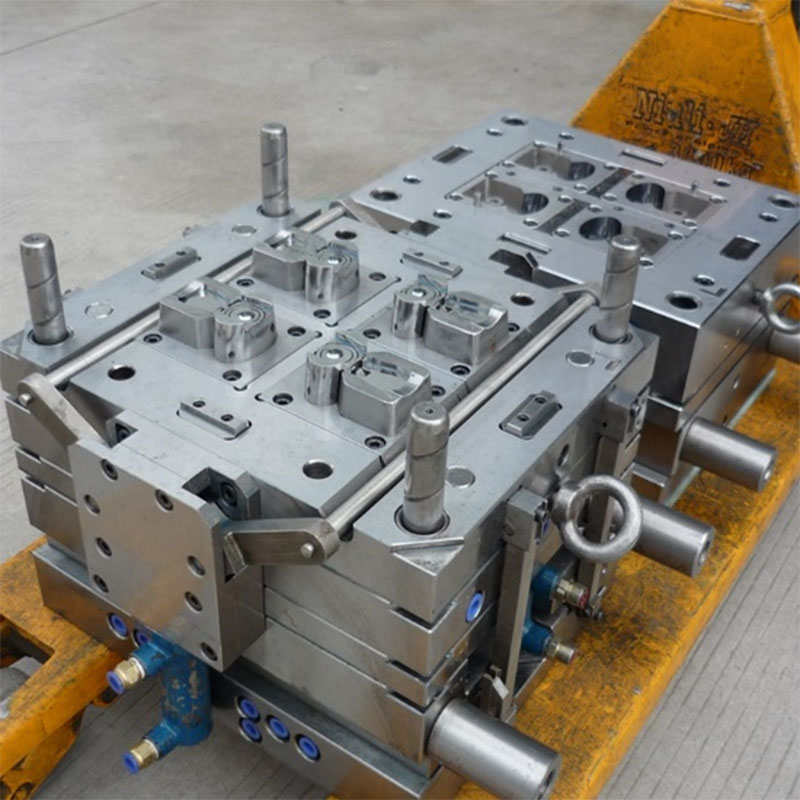

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

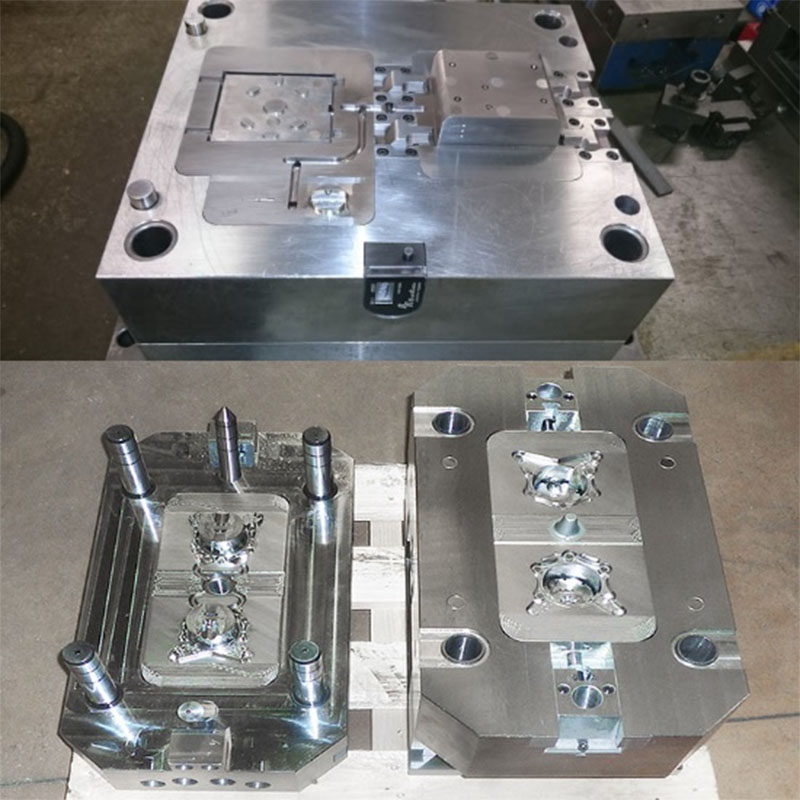

Plastic injection mold manufacturing Injection Mould making

1.We communicate product design according to samples/drawings and your requirements.

2.After the product design is confirmed, we carry out the mold design, we provide all kinds of injection molds, blow molds, silicone molds, die-casting molds services.

3.Material procurement, steel cutting and mold basic tools.

4.Mold assembly

5.Mold inspection, tracking and controlling mold processing.

6. We will inform you the date of mold trial and send you the sample inspection report and injection parameters together with the sample.

7.Your instruction and confirmation of shipment.

8.Prepare the mold before packing.

Plastic injection mold manufacturing molding Specification

1. Professional manufacturer, design, production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Transaction process:

Mold testing:

Once the mold is complete, I do a mold test. It usually takes about 3-5 days to complete. We need to assemble the mold, adjust the pressure data of the machine, and try production. We need to check whether there are problems during the normal production of the mold and make modifications.

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

Factory

Video-1: (Factory Video)

Video-2: (Injection Molding)

Video-3: (Blow molding)

Video-4: (Blow molding)

Video-5: (Roll molding)

Customer satisfaction is our most important goal. We focus on communication and cooperation with our customers, always pay attention to their needs and provide quick response and quality customer service. Our injection production mold factory is committed to establishing long-term relationships and ensuring that our customers receive the best after-sales service during the purchase and use of our products, and we will definitely do our best to solve any problems for our customers.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us?

Mould,Plastic Product, Metal Product,Dental Product,CNC machining.

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6. What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.