How we become an excellent injection mold maker

2025-09-05

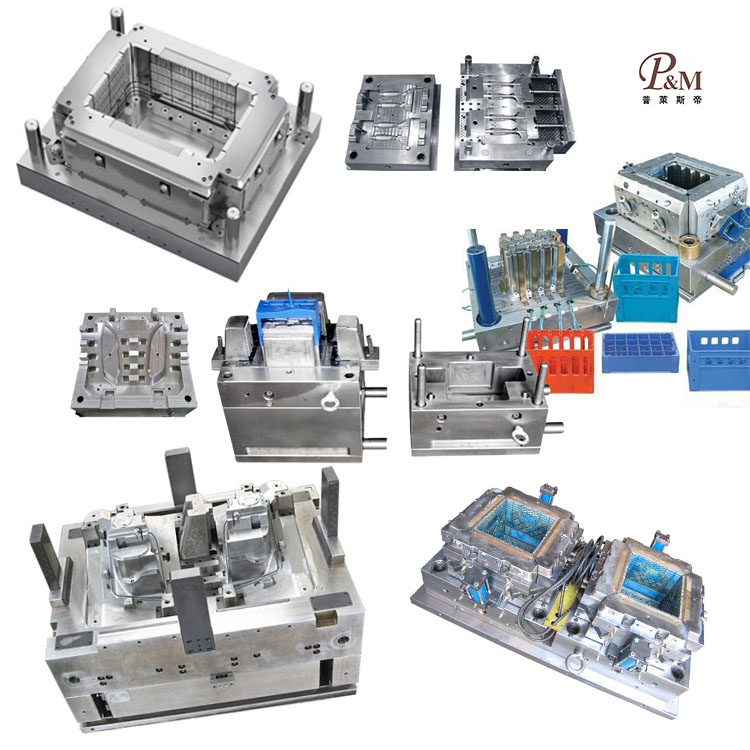

A systematic strategy to become an excellent injection mold manufacturer integrates four key dimensions: quality, technology, management, and service:

I. Design and R&D Innovation

In-depth Product Analysis

100% rigorous verification is required during the plastic part design phase to avoid rework later. Mold flow analysis is used to optimize runner design and ensure flow balance and dimensional consistency in multi-cavity molds.

Using an integrated CAD/CAM/CAE system, we achieve integrated design and manufacturing, shortening development cycles by 2%.

Mold Structure Optimization

Complex cooling system design improves molding efficiency and reduces product defects by 10%.

Compatibility with Automated Production: The ejection system must be compatible with robotics to achieve burr-free, reshaping-free demolding, eliminating manual intervention.

2. Precision Manufacturing and Process Control

Materials and Processing

Core components (core/cavity) are made of highly wear-resistant steel (such as 1.2344 and S136). Material reports are submitted to ensure traceability.

Precision machining equipment ensures accuracy: CNC machine tools, EDM, and wire-cutting equipment are essential. Post-processing heat treatment is required to relieve stress. Process Standardization

Establish a process parameter database and continuously optimize parameters such as injection temperature and pressure through testing.

Strict process quality inspection: Dimensional inspection at each stage, with part fit accuracy ≤ 0.02mm (referring to battery mold standards).

3.Full-chain Quality Management

Incoming Materials and Process Control

Raw materials are stored in a classified manner, and batch performance testing is performed to prevent moisture and deterioration.

Implement the "Three No's Principle": Do not accept, do not create, and do not transmit defects (e.g., Sino Mold's zero-tolerance culture).

Lifespan and Reliability

Mold lifespan ≥ 1 million cycles, with surface grinding/polishing to enhance corrosion resistance.

Maintain molds regularly, replace consumable parts (e.g., hot runner heating elements), and maintain a sufficient spare parts inventory.

4.Technology Upgrade and Talent Development

Intelligent and Data-Driven

Introduce IoT technology to monitor equipment status and adjust parameters in real time to reduce scrap rates (e.g., Gongyu Precision Solutions).

Develop a mold production management system to optimize tool scrap control and work order processes.

Team Capacity Building

Equity incentives for core technical personnel align talent with company interests. Regular skills training is conducted to reinforce the "cost is profit" philosophy (e.g., the 12 Principles for Injection Molding Employees).

5.Customer Collaboration and Value-Added Services

Customized Response

Rapid prototyping capabilities (≤55 days), providing a one-stop solution from factory construction to mass production.

After-sales Guarantee: One-year free warranty and lifetime technical support.

Transparent Cooperation

Provide mold flow analysis reports, material certifications, and share key technical parameters upon delivery.

Pre-sales coordination with customers regarding product functional requirements to avoid mass production risks caused by design flaws.

Industry Certification and Brand Building

Achieve ISO 9001 and other system certifications and participate in the development of industry standards (e.g., the Acceptance Specifications for Sail Plastic Molds).

Accumulate technical patents to strengthen the "high-precision mold manufacturer" label.

The ultimate goal of an excellent manufacturer: to avoid problems through design, earn trust through precision, and reduce costs through longevity. Continuously benchmark against leading companies, transforming technological advancements into an "inspection-free pass" for clients.

To gain a foothold in the fiercely competitive foreign trade sector, outstanding injection mold manufacturers must combine technical strength, market strategies, and digital transformation.

1. Strengthen Core Technologies and Build Differentiated Competitive Advantages

Breakthroughs in Lightweighting and Precision Technologies

Develop cutting-edge technologies such as thin-wall injection molding (e.g., 1.8mm wall thickness molds), microcellular foaming, and composite material injection molding to meet lightweighting needs in industries like automotive and medical.

Process Standardization and Precision Control

Establish a full-process quality control system. Through 30-50 process controls, maintain precision within 0.005mm, earning the trust of foreign clients.

2. Actively Expand International Markets and Accurately Target Customers

Multi-Dimensional Customer Development

Online Channels:

Leverage Google Advanced Search (keywords such as "Injection mold + importer"), customs data, and LinkedIn to identify potential customers.

Marketing on B2B platforms such as Alibaba International and Made-in-China.com, while integrating proactive development (e.g., email marketing) to increase conversion rates.

Offline Resources:

Obtain listings at international exhibitions, focusing on pursuing clients in high-demand sectors such as automotive, medical, and consumer electronics. Customized Services and Niche Market Focus

Provide differentiated solutions for different markets, such as environmentally friendly molds for European and American customers and cost-effective products for emerging markets.

Case Study: Dongguan Yuxin Mold focuses on niche areas such as sweeper housings and automotive parts, attracting foreign trade orders through rapid response (molding within 10 days).

3. Promote Intelligent and Digital Transformation

Digitalization of Production Processes

Introducing intelligent design software and MES systems (such as Heihu Mini-Work Orders) enables real-time monitoring of production progress, reducing data error rates by over 25%.

Benefits: Through equipment upgrades, production efficiency increased by 40%, and labor costs decreased from 30% to 20%.

Supply Chain and Remote Service Optimization

Establish a cloud-based operations and maintenance system to support remote mold commissioning and troubleshooting, enhancing international customer trust.

4.Build Brand Trust and Risk Management Systems

Technical Certification and Case Endorsement

Obtain ISO certification and patented technologies, and strengthen brand credibility through successful cases (such as collaborations with major foreign manufacturers).

Risk Response Strategies

Market Risks: Monitor policy changes (such as carbon tariffs) and flexibly adjust export market layout. Supply Chain Risk: Collaborate with multi-regional logistics providers to mitigate geopolitical impacts on delivery.

5 Long-Term Strategy: Integrate Global Trends with Localized Services

Green Manufacturing: Develop low-carbon mold processes to address regulations like the EU carbon border tax.

Localization Team: Establish service points in key markets (such as Southeast Asia and Europe) to provide rapid response and technical support.

Summary

To thrive in foreign trade, a company must build on its technological strengths (e.g., lightweighting and precision manufacturing). Efficiency must be improved through proactive customer acquisition (online and offline) and digital empowerment (smart production and remote services). Furthermore, a company must cultivate sustainable advantages through deep dives into niche areas and proactive risk assessment. By aligning internal innovation with market demand, companies like Kaixincheng and Hitech can successfully navigate the competitive landscape of foreign trade.