The application of injection mold inserts

2025-09-26

Inserts are very common and important components in mold design. Understanding and applying inserts well is crucial for the manufacturing, use and maintenance of molds.

I. What are injection mold inserts?

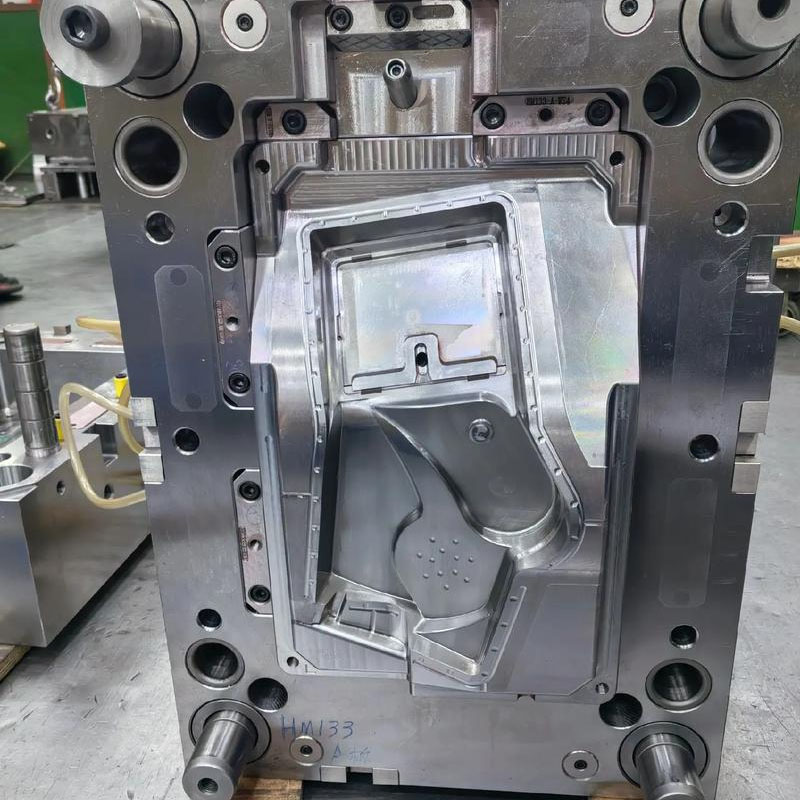

Inserts refer to parts that are embedded inside the mold kernel (core or cavity) and can be processed independently. It is not made from a single piece of steel but adopts a "modular" structure. The mold core is the main body, while the insert is the part.

In simple terms, the mold core can be imagined as the motherboard of a mobile phone, while the inserts are like various chips and slots on the motherboard, which can be independently installed, replaced and upgraded.

Ii. Main Application Scenarios of Inserts (Why Use inserts?)

The use of inserts is mainly to solve a series of problems in mold manufacturing, use and maintenance, and its application scenarios are very extensive.

It is convenient for processing and reduces manufacturing difficulty

Deep cavity and narrow groove processing: For some very deep and narrow ribs or grooves on the mold, if they are directly processed on the entire mold core, the cutting tools (milling cutters, electrodes) will be long and thin, prone to vibration, wear and even breakage, resulting in low processing efficiency and difficulty in ensuring precision. After being designed as independent inserts, they can be processed separately, or even better techniques such as wire cutting can be adopted, which greatly reduces the processing difficulty and cost.

Complex shape processing: For parts with particularly complex shapes that are difficult to polish, after being made into inserts, they can be finely processed, polished or etched (such as leather grain, bite pattern) separately, and the effect will be better.

2. Easy to maintain and replace, it can increase the service life of the mold

Vulnerable parts: Some parts of the mold are prone to wear, erosion or damage during the injection molding process, such as

Small cores (through/insert positions) : These positions are subject to greater force during mold closing and are prone to chipping or wear.

Near the gate: The high-speed and high-pressure plastic melt is constantly eroding, which is prone to damage.

If the entire mold core is made into one piece, once these local parts are damaged, the entire expensive mold core needs to be repaired or replaced, which is costly and time-consuming. After using the inserts, only the damaged ones need to be removed for repair or replaced with new ones. "Replace where it's broken", which greatly saves time and cost.

3. Optimize the mold cooling system

Local enhanced cooling: Some areas on the product are particularly thick and prone to shrinkage marks. Cooling water channels can be designed separately within the corresponding inserts in this area for targeted enhanced cooling, effectively improving product quality.

Solving waterway interference: Sometimes the cooling waterways on the mold core may interfere with ejector pins, screws, etc. By using inserts, the waterway can be designed inside the inserts, ingeniously avoiding interference issues.

4. Save high-quality steel and reduce costs

Mold cores usually require the use of high-performance and expensive mold steels (such as S136, H13, etc.) to ensure overall strength and service life.

For some local special structures (such as slender cores), special steels with better toughness or greater wear resistance (such as cemented carbide) can be used to make inserts. This not only meets the local high-performance requirements but also avoids the use of high-priced materials for the entire mold core, achieving cost optimization.

5. Convenient for exhaust

The mating surface between the insert and the mold core can naturally form an exhaust groove, which helps to expel the air in the cavity and the gases produced by the decomposition of the plastic, reducing defects such as trapped gas and burning in the product.

6. Achieve product diversification

By replacing different inserts, it is possible to achieve changes in different parts of the product on the same set of molds, such as printing out series products with different dates, logos or specifications, which enhances the flexibility of the molds.

Iii. Common Types of Inserts

Through-hole inserts: Insert from the back of the mold core and fix with screws or pressure plates. It is the most common type with stable installation.

Blind hole inserts (mounting inserts) : Embedded from the front of the mold core and positioned by the mounting (step) at the bottom to prevent detachment. It is suitable for situations where it cannot be installed from the back.

Circular inserts: Mainly used for forming cylinders, holes, etc., and are easy to process.

Irregular-shaped inserts: Their shapes are consistent with the local structure of the product and are used to form complex features.

Iv. Challenges That May Arise from Using Inserts

Although it has many advantages, some issues should also be noted when using inserts:

High fit accuracy requirements: The fit clearance between the insert and the die core must be strictly controlled. Excessive gap will cause flash (burrs), affecting product quality. If the gap is too small, it will be difficult to assemble and may even get stuck.

Adding assembly steps: The increase in the number of parts in the mold raises the complexity and time of assembly.

There may be seam lines: The seam between the insert and the mold core will leave a mark (parting line) on the product. If the design or processing is improper, this mark will be very obvious and affect the appearance.