The importance of Electrical discharge Machining (EDM) for injection molds

2025-09-26

Electrical discharge machining (EDM, abbreviated as "EDM machine") is not "important" but "indispensable" for injection molds. It is a key technology for manufacturing high-precision and high-quality molds, especially having irreplaceable advantages in processing high-hardness steel and complex geometric shapes.

It can be said that without electrical discharge machining, there would be no modern precision injection molds.

The following is a detailed elaboration on the significance of electrical discharge machining for injection molds, mainly divided into several core aspects:

I. What core problems does electrical discharge machining solve?

"Softness overcomes hardness" - Processing high-hardness materials

Background: The cavity of the mold is usually made of high-hardness and high-wear-resistant mold steel (such as H13, S136, etc.), and undergoes heat treatment (quenching) to achieve high hardness (above HRC50). Traditional milling tools will wear out sharply when processing such hard materials, and may even be unable to cut at all.

The advantages of EDM: Electrical discharge machining is a "non-contact" processing method that uses the high temperature generated by pulsed discharge to locally melt and vaporize metals. The removal capacity of a material is not related to its hardness but only to its melting point and thermal conductivity. Therefore, it can easily process high-hardness steel after quenching and ensure processing accuracy.

"Omnipresent" - Forming complex geometric shapes

Background: Injection-molded products typically contain various geometric features that are difficult or even impossible to process on CNC milling machines, such as

Deep cavities and narrow grooves: The length and diameter of the cutting tool are restricted, making it impossible to penetrate or lacking rigidity.

Sharp corners and clear corners: The milling cutter itself is circular and cannot produce absolute right angles or inner sharp corners.

Fine textures: Leather grain, bite patterns, etc. on the surface of the mold.

Deep rib position: If the length-to-diameter ratio of the tool is too large, it is prone to springback and the accuracy cannot be guaranteed.

The advantages of EDM: It can produce cavities that are exactly the same as the shape of the electrode. As long as electrodes can be manufactured, no matter how complex their shapes are, they can be precisely replicated onto die steel.

"Striving for excellence" - achieving extremely high surface quality and precision

Background: The surface requirements for molds are extremely high. For instance, transparent parts need a mirror finish, and appearance parts require specific textures.

The advantages of EDM: By precisely controlling electrical parameters (current, voltage, pulse time), especially by using mirror electrical discharge technology, a mirror effect of VDI 18 (A1) grade or above can be directly processed on die steel without subsequent polishing or greatly reducing the polishing workload. Meanwhile, the processing accuracy can reach ±0.002mm or even higher.

Ii. Specific Application Scenarios of Electrical Discharge Machining in Mold Manufacturing

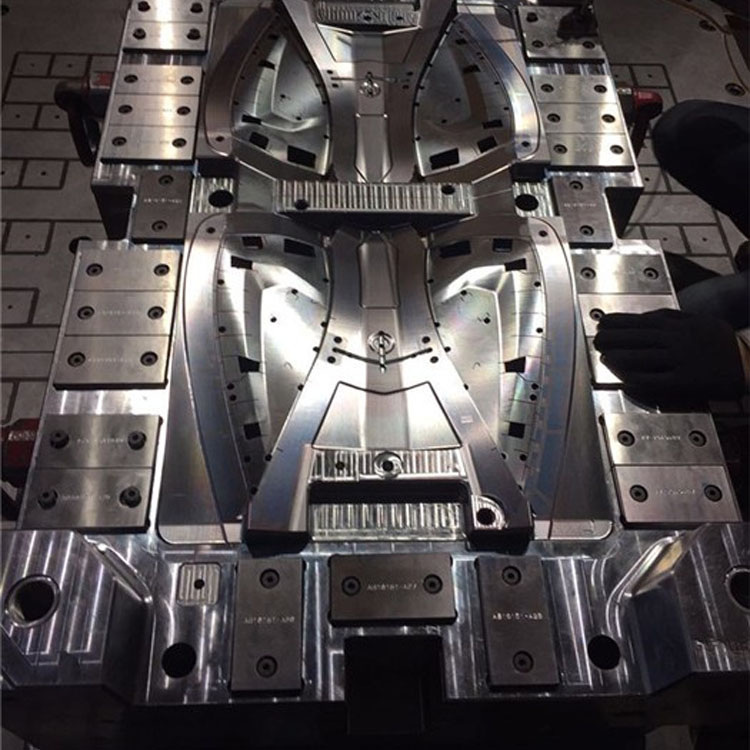

Cavity/core forming: This is the most important application. Used for processing the main contour of the product, especially the parts containing the above-mentioned complex features.

The processing of sliders and inclined tops: These moving parts have complex shapes and require high hardness. EDM is the preferred process.

Processing of text and logos: The concave or convex characters on the mold are usually etched by EDM, which are clear and permanent.

Processing of deep ribs: For deep and thin ribs used for reinforcement on products, EDM is the best choice, which can ensure dimensions and avoid stress.

Mold maintenance and modification: For molds that have already undergone heat treatment, if modification or repair after welding is required, EDM is the only effective means.

Iii. Types of Electrical Discharge Machining and Their Significance

Forming machine (cavity processing

Principle: Use pre-processed copper or graphite electrodes that are opposite in shape to the product to "copy" the cavity through discharge.

Importance: It is the core means for processing complex three-dimensional curved surface cavities.

Wire Cutting (WEDM

Principle: A moving metal wire (molybdenum wire) is used as an electrode to perform two-dimensional contour cutting.

Importance

Processing inserts: Precisely cut inserts for vulnerable parts or special materials.

Processing punches/electrodes: Prepare high-precision electrodes for forming machines.

Corner cleaning treatment: Clear absolute right angles for the cavity.

Summary: The core value of electrical discharge machining

Feature: The importance of injection molds

Not limited by hardness: It allows the mold to undergo heat treatment first (to enhance service life and stability) before fine processing, avoiding the impact of heat treatment deformation on accuracy.

Replicating complex shapes: Enabling molds to achieve any complex appearance and structure required by product designers is the technical guarantee for product innovation.

High precision/mirror effect: It directly determines the dimensional accuracy, assembly performance and appearance quality (gloss, texture) of injection molded products.

Corner cleaning ability: It can process absolute right angles and sharp corners to meet special design requirements.

Conclusion: Electrical discharge machining and CNC milling are complementary and mutually reinforcing. In modern mold manufacturing processes, CNC is responsible for the rapid removal of "rough" contours and most geometric shapes, while electrical discharge machining (EDM) is in charge of "refining" the details, tough nuts and final surface effects that CNC cannot reach. It is the key technology for transforming a hard die steel into a precise functional work of art