Introduction of mold carving

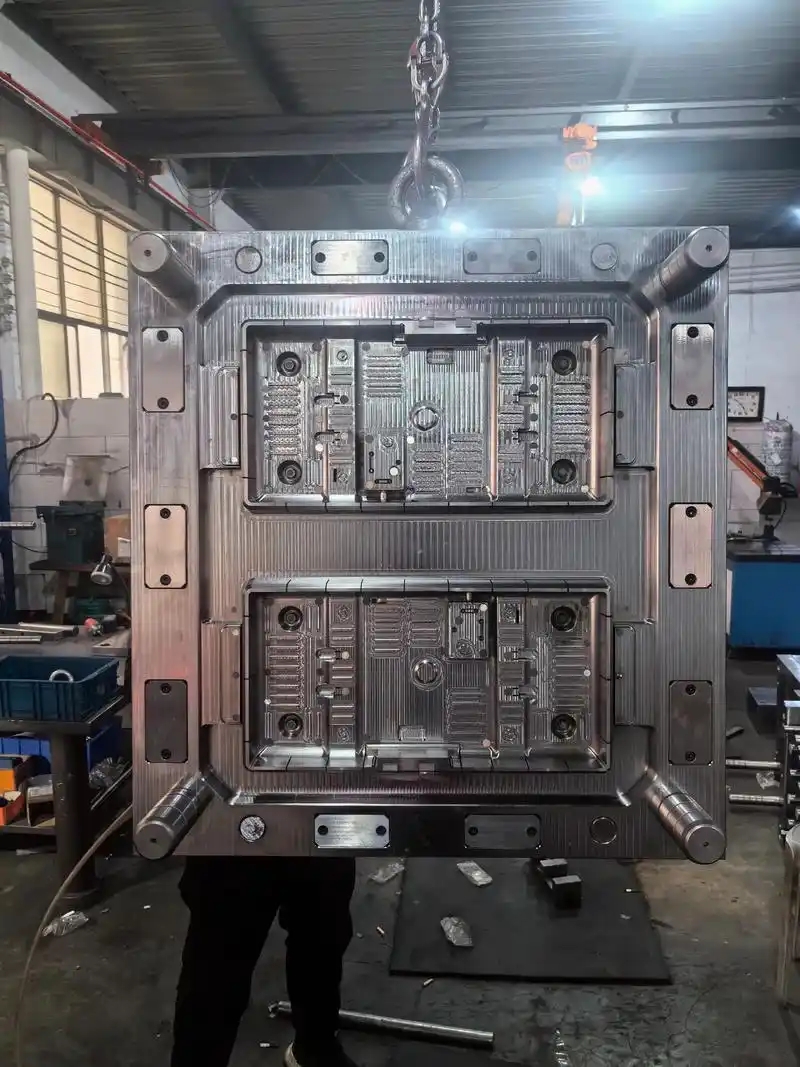

Mold carving is a process of forming complex textures or patterns on the surface of the mold, which can be transferred to the surface of the final product, giving the product a unique appearance. The following is a detailed introduction to mold carving:

Definition of mold carving

Mold carving is a technology for making patterns or textures on the surface of the mold, which are then transferred to the surface of the product. It is common in the fields of plastic products, metal processing, etc.

Process types of mold carving

Mechanical carving: using mechanical tools to carve on the surface of the mold, suitable for fine processing of complex patterns.

Laser carving: by irradiating the mold surface with a high-energy laser beam, the material evaporates or melts instantly to form a carved pattern, which is suitable for processing high-precision and complex patterns.

Advantages and disadvantages of mold carving

Advantages:

Improve the aesthetics and tactile experience of the product.

It has certain functionality, such as improving the wear resistance and anti-fouling ability of the product.

Process innovation can give the product unique artistic value and personalized design.

Disadvantages:

Some processes may damage the mold and increase the subsequent maintenance cost.

High-precision engraving technology is expensive and suitable for specific high-end application scenarios.

Application fields of mold carving

Architectural decoration: used for building exterior walls, floors or interior decoration to increase beauty and artistry.

Plastic products: make special textures on the surface of plastic products, such as car interiors, home appliance shells, etc.

Metal processing: Carve on the metal surface to make metal products with unique appearance

The development of mold carving technology can be traced back to ancient times, and has undergone an evolution from manual skills to mechanized production. The following are its main development stages:

Ancient mold carving

The history of mold carving can be traced back to the production of ancient ceramics and bronzes. The earliest mold carving was mainly used to make molds to meet the needs of handmade products.

Handcraft period

Before the Industrial Revolution, mold carving was mainly completed by manual skills. Craftsmen used various hand tools, such as chisels, chisels, etc., to carve on metal materials. Although this method is time-consuming and labor-intensive, it can achieve a high degree of accuracy and the production of complex patterns.

The early stage of mechanized production

Entering the 20th century, with the advancement of the industrial revolution, mold carving began to gradually shift to mechanized production. The earliest mechanized equipment included milling machines and grinders, which can improve processing efficiency and precision.

Mid-to-late 20th century

Application of CNC technology (CNC): In the 1970s, CNC technology began to be applied to mold carving, and computer programming was used to achieve precise control of the processing process, greatly improving production efficiency and product quality.

Introduction of laser engraving technology: In the 1980s, laser engraving technology began to become popular. This technology uses high-energy laser beams for engraving, with high precision and high efficiency, and is suitable for the processing of various metal and non-metal materials.

21st century

Intelligence and automation: With the development of artificial intelligence and big data technology, the mold carving industry has entered a new era of intelligence and automation. The application of intelligent CNC systems and automated production lines makes mold carving more efficient and accurate.

Integration of 3D printing technology: The application of 3D printing technology has brought revolutionary changes to mold carving, which can directly convert digital models into physical products, shorten the product development cycle, and realize the production of complex shape molds.

Here are some ways to improve the efficiency of injection mold carving:

1. Mold design and optimization

Reasonable layout of carving position

In the early stage of mold design, the location of the carving should be planned. Avoid carving in stress concentration areas or parts that affect the structural strength of the mold. This can reduce the number of modifications in subsequent processing and improve overall efficiency.

Simplify the carving pattern

If the product allows, try to simplify the carving pattern. Overly complex patterns will increase the difficulty and time of processing. For example, simplify some complex curves into a combination of straight segments or arcs.

2. Equipment and technology selection

Select advanced equipment

Using high-precision CNC processing equipment can improve the accuracy and speed of carving. For example, a high-speed cutting center can complete complex carving tasks in a short time.

For laser carving equipment, choose models with stable energy and fast speed. Some new laser carving equipment can achieve higher power and faster scanning speed, thereby improving carving efficiency.

Use advanced carving technology

For example, using multi-axis linkage processing technology, complex carving patterns can be processed at one time, reducing the time for multiple processing.

Use high-speed laser engraving technology to increase the speed of laser engraving while ensuring the quality of engraving.

3. Process optimization

Tool or laser parameter optimization

In mechanical engraving, reasonably select parameters such as tool diameter, blade angle, speed and feed rate. Appropriate tool parameters can increase processing speed and reduce tool wear.

For laser engraving, adjust parameters such as laser power, spot diameter, scanning speed, etc. By optimizing these parameters, the engraving speed can be increased while ensuring the quality of engraving.

Use layered engraving

For thicker engraving parts, layered engraving can be used. Carve shallow layers first, and then gradually deepen the depth of engraving. This can avoid processing difficulties and extended time caused by one-time engraving too deep.

4. Production management and personnel training

Reasonable production plan

According to order requirements and the complexity of the mold, reasonably arrange the order and time of engraving production. Avoid idle molds or excessive rushing.

Personnel training

Provide professional training for operators to enable them to master the operating skills of equipment and processes. Skilled operators can adjust equipment parameters more quickly, reducing errors and downtime in processing, thereby improving efficiency.