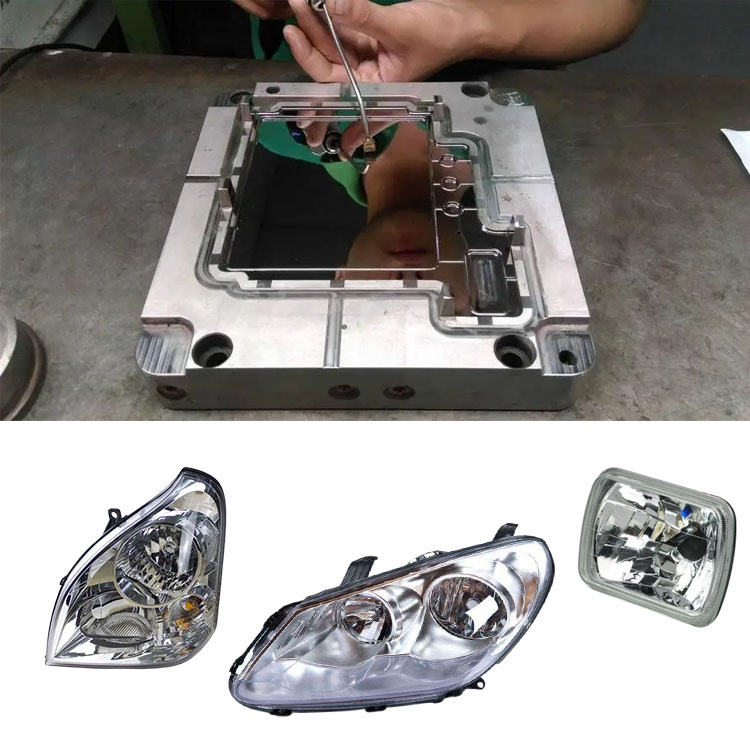

PC Lens Injection Mold Process

2025-08-01

PC (polycarbonate) lens injection mold technology is a high-precision optical product molding process that requires extremely strict mold design, material selection, and process control. The following are key process points:

1. Mold Design Key Points

Material Selection

Mold steel requires high hardness and high wear resistance (such as S136, H13, etc.), mirror polished to Ra ≤ 0.01μm, to avoid surface defects that affect light transmittance.

Chrome plating or nickel-phosphorus coating can enhance corrosion resistance and mold release.

Runner and Gate Design

Hot runner systems are preferred to minimize material degradation caused by cold material and shear heat.

Gating locations should be positioned away from the optical area (typically using fan-shaped or point gates) to avoid weld marks and flow lines.

Cooling System

Use a uniform layout (conformal cooling channels are optimal) and control the temperature difference within ±1°C to prevent uneven shrinkage that can cause warping or stress.

Venting Design

Venting grooves should be 0.01-0.02mm deep to prevent trapped air from causing bubbles or burning.

2. Injection Molding Process Parameters

Drying

PC requires drying at 120°C for 4-6 hours, with a moisture content of ≤0.02% to prevent hydrolysis and embrittlement.

Melting Temperature

280-320°C (adjusted depending on PC grade). Higher temperatures can lead to degradation, while lower temperatures can result in poor fluidity.

Injection Pressure and Speed

Medium-high pressure (80-120 MPa) combined with multi-stage injection: High-speed filling prevents cold slugs, while a reduced speed at the end reduces internal stress.

Holding and Cooling

Holding pressure is 50-70% of the injection pressure, and the holding time is adjusted based on wall thickness (usually 10-30 seconds).

Cooling time should account for at least 50% of the cycle to ensure sufficient curing.

Mold Temperature Control

Mold temperature is 80-110°C. Higher temperatures can lead to mold sticking, while lower temperatures can result in a rough surface.

3. Post-Processing and Inspection

Annealing

Anneal at 110-130°C for 2-4 hours to eliminate internal stress and improve dimensional stability.

Surface Coating

Hard coatings (such as SiO₂) enhance abrasion resistance, while anti-reflective coatings improve optical performance.

Quality Inspection

Optical Properties: Transmittance (≥90%), refractive index, and Abbe number.

Mechanical Properties: Impact resistance (typical value for PC: ≥60 kJ/m²), hardness.

Defect Inspection: Bubbles, streaks, and impurities (100% inspection).

4. Common Problems and Solutions

Surface Silver Streaks: Moisture or degradation; strict drying and lowering the melt temperature are recommended.

Bubbles: Poor venting or insufficient holding pressure; optimize venting and increase holding pressure.

Warp: Uneven cooling or stress concentration; adjust mold temperature and optimize gate location.

Optical Distortion: Insufficient mold polishing or uneven shrinkage; re-polish and improve the cooling system.

The injection molding process for PC (polycarbonate) lenses involves precision mold design, strict process parameter control, and post-processing to ensure that optical properties (such as transparency and refractive index) and mechanical properties (such as impact resistance and abrasion resistance) meet standards. The following is a detailed process flow:

1. Raw material pretreatment

Drying

PC has strong hygroscopicity and needs to be dried at 120℃ for 4-6 hours (adjusted according to particle size and humidity), and the moisture content must be ≤0.02%.

Use a dehumidifying dryer to avoid secondary moisture absorption (recommended dew point ≤-40℃).

Color matching (optional)

If dyeing is required, optical grade masterbatch should be used to avoid impurities affecting the transmittance.

2. Injection molding stage

(1) Melt plasticization

Temperature control

Barrel segment heating: rear section (240-260℃) → middle section (270-290℃) → front section (280-320℃) to avoid local overheating and PC degradation.

Screw speed ≤80 rpm to reduce molecular chain breakage caused by shear heat.

(2) Injection molding

Multi-stage injection

First stage: high-speed filling (to prevent cold material), injection speed 50-80% of the maximum speed.

Second stage: Reduce speed to 20-30% to reduce weld marks and internal stress.

Pressure: Injection pressure 80-120MPa, holding pressure 40-60MPa (to maintain shrinkage).

Mold temperature control

Mold temperature 80-110℃, using oil temperature controller or high-precision mold temperature controller, temperature difference within ±1℃.

(3) Holding pressure and cooling

Holding pressure time: 10-30 seconds (adjusted according to wall thickness, usually estimated as 1mm thickness ≈ 1 second).

Cooling time: more than 50% of the total cycle (usually 20-60 seconds) to ensure that the lens is fully cured.

(4) Demolding

The ejection system needs to be stable (such as pneumatic ejection or servo ejector) to avoid whitening or scratches.

The demoulding slope is ≥1°, and a release agent is sprayed if necessary (it must not affect subsequent coating).

3. Post-processing process

(1) Annealing treatment

Conditions: Anneal in an oven at 110-130℃ for 2-4 hours, and slowly cool to room temperature.

Purpose: Eliminate internal stress and reduce subsequent deformation or optical distortion.

(2) Surface treatment

Hard coating: Improve surface hardness (up to 4H or above) through vacuum coating (such as SiO₂, TiN).

Anti-reflective coating: Multi-layer coating (MgF₂, etc.) reduces glare and increases light transmittance to more than 99%.

(3) Cleaning and inspection

Ultrasonic cleaning removes release agent and dust, using a dust-free workshop environment.

100% full inspection: transmittance (spectrophotometer), surface defects (automatic optical inspection AOI), dimensional accuracy (three-dimensional measurement).