- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Pmma injection moulding

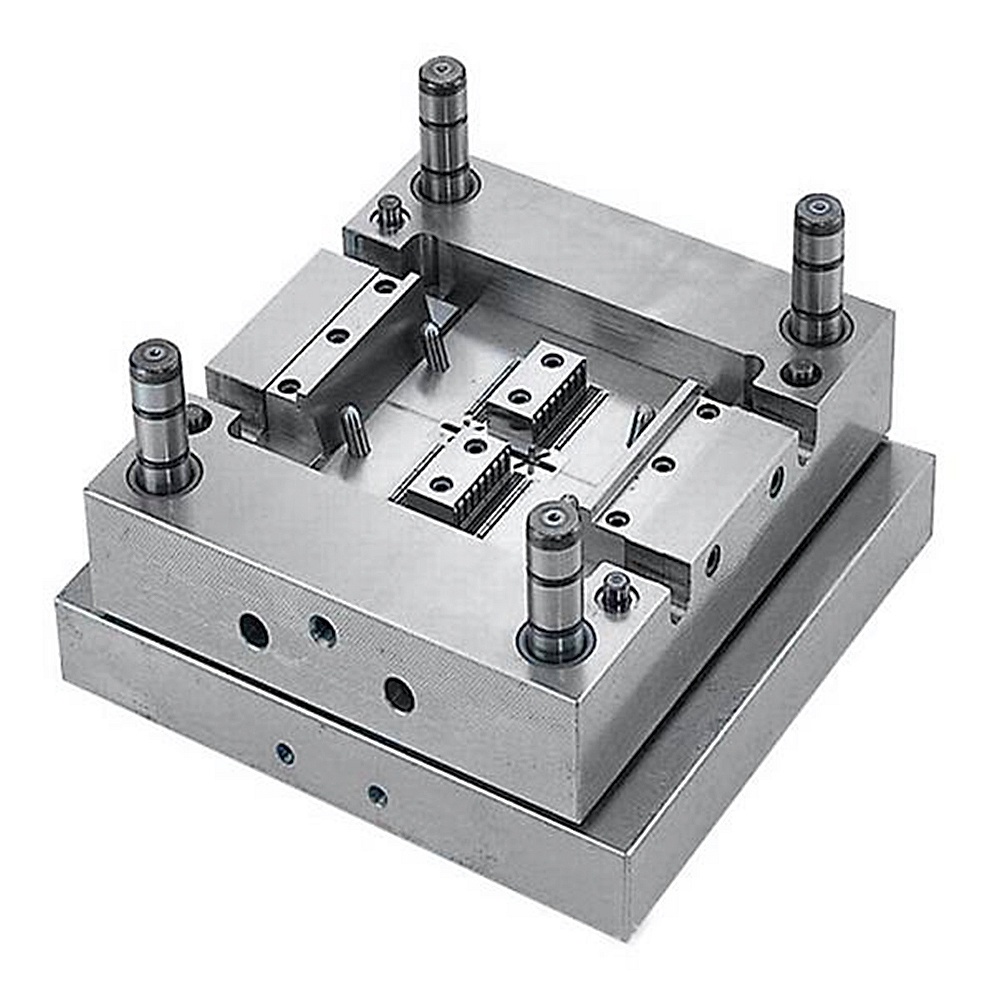

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize pmma injection moulding. We provide professional customized pmma injection moulding services, and we are a professional pmma injection moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing pmma injection moulding, our factory can provide one-stop service. We have design and production capabilities related to pmma injection moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized pmma injection moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For pmma injection moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

Let's take a comprehensive and in-depth look at the injection molding of PMMA (polymethyl methacrylate, commonly known as acrylic or plexiglass).

PMMA is renowned for its exceptional optical clarity, high surface hardness, excellent weather resistance, and good chemical resistance. This makes it highly popular in applications requiring high transparency and aesthetics, such as optical lenses, light guides, automotive taillights, instrument panel covers, display housings, and cosmetic containers.

The injection molding process demands extremely high precision and cleanliness; any negligence will be clearly revealed in the transparent finished product.

Detailed Explanation of the PMMA Injection Molding Process

Phase 1: Pre-molding Preparation (Critical)

This is the most critical step in the success of PMMA injection molding. Without proper preparation, all subsequent efforts will be in vain.

Raw Material Selection and Pretreatment (Critical! Critical! Critical!)

Material Selection: Select injection-molding-grade PMMA granules based on product requirements. Common grades include Chimei's CM-205 and CM-211, and Mitsubishi's VR series. Different modified specifications may be available, including UV resistance, antistatic properties, and high flow properties.

Drying and Dehumidification: PMMA is a highly hygroscopic material, so this must be taken very seriously.

Why is drying necessary? PMMA granules absorb moisture from the air during storage and transportation. If these granules, which contain moisture, are directly injected into the mold, the moisture will vaporize at high temperatures, resulting in indelible silver streaks (silver streaks), bubbles, and cloud-like haze. This can also cause polymer hydrolysis, leading to a decrease in molecular weight, brittleness, and a sharp deterioration in mechanical properties.

Drying Process: A dehumidifying dryer must be used (conventional hot air dryers are ineffective), drying continuously at 80-90°C for at least 2-4 hours. The moisture content of the dried granules must be below 0.03% (ideally <0.02%).

Note: Dried granules will quickly regain moisture when exposed to air. Therefore, the drying hopper should be directly connected to the injection molding machine inlet and kept tightly closed. If the machine is down for more than 30 minutes, the hopper may need to be re-dried.

Mold Preparation

Mold Design: The cavity surface must be mirror-polished (#10000 or higher diamond paste polish). Any minor scratches will be replicated on the part surface. Runners and gates should be smooth, free of stagnation points, and minimize weld marks.

Mold Cleaning: Before closing the mold, the cavity must be thoroughly wiped with a dust-free cloth, high-purity alcohol, or a dedicated mold cleaner. Any trace of dust, oil, moisture, or residue from the previous mold can cause fatal defects.

Mold Temperature Controller (Mold Temperature Control): Prepared to preheat and maintain the mold at the optimal temperature (typically 60-80°C).

Phase 2: Injection Molding Cycle (Fine Control)

Process parameters are set based on the principles of "gentle and uniform," avoiding any harsh operations that could cause material decomposition or stress.

1. Mold Closing

The mold is locked under high pressure.

2. Injection and Holding Pressure

Barrel Temperature: PMMA has a narrow processing temperature range, typically set between 210-270°C.

Too low a temperature: The melt has poor fluidity, resulting in incomplete filling, surface flow marks, and noticeable weld lines.

Too high a temperature (above 280°C): The material may decompose, yellowing, bubbles, and black specks may occur.

Injection Speed: Medium to low injection speeds are recommended.

High injection speeds can easily cause high shear stress, leading to shear overheating, localized material decomposition (producing black specks), and gas entrainment.

Slow injection speeds facilitate degassing, reducing bubbles and silver streaks, but may also make weld lines more noticeable. Finding a balance depends on the product structure. Multi-stage injection molding is typically used, with slow filling speeds in thick-walled areas to facilitate degassing and fast injection speeds in thin-walled areas.

Holding Pressure: Use medium to low holding pressures and short holding times. Excessively high holding pressures and long holding times can generate significant internal stresses, making the product susceptible to stress cracking during subsequent use. The primary purpose of holding pressure is to compensate for shrinkage, not to compact the product.

3. Cooling

Mold temperature: This is crucial and should generally be maintained between 60-80°C.

If the mold temperature is too low, the melt rapidly cools upon contact with the cold mold wall, "freezing" the molecular chains. This results in poor flow, weak weld lines, and extremely high internal stress in the product.

If the mold temperature is too high, the cooling time is prolonged, production efficiency is low, and mold sticking is likely to occur.

Cooling time: Ensure that the product is fully cooled and formed to prevent deformation during ejection.

4. Mold Opening and Ejection

PMMA is a brittle material with a high surface hardness. The ejection system must be balanced and uniform.

Avoid using sharp ejector pins. It is recommended to use large-area ejectors (strippers), push blocks, or gas-assisted ejection to prevent white spots, cracks, and obvious ejection marks.

Stage 3: Post-Processing and Inspection

Gate Removal: Carefully cut or punch out the gate and runners. Trimmed areas should be ground and polished to restore transparency and aesthetics.

Annealing (Stress Relief - Highly Recommended)

Purpose: Eliminate internal stresses generated during the injection molding process, significantly improve the product's chemical resistance (especially solvent resistance) and dimensional stability, and prevent future stress cracking.

Process: Place the product in a circulating air oven, slowly heat it to 70-80°C (10-20°C below the heat distortion temperature), hold it there for 2-4 hours, and then slowly cool it to room temperature. Rapid heating and cooling will introduce new stresses.

Surface Treatment (Optional):

Polishing: Products with minor surface blemishes or sprue marks are polished to restore a mirror finish.

Hard Coating: Spray hardening is sometimes performed to improve surface scratch resistance.

Full Inspection and Packaging

Appearance Inspection: 100% inspection is conducted under a backlit inspection light, carefully checking for any defects such as silver streaks, bubbles, black spots, scratches, shrinkage, weld marks, and impurities.

Dimensional Inspection: Use calipers, projectors, and other tools to inspect critical dimensions.

Performance Inspection: Tests such as light transmittance and haze.

Packaging: Individually isolate and package items using soft materials (such as PE bags, foam pads, or paper interlayers) to prevent scratching. Operators must wear gloves.

We are a pmma injection moulding manufacturer, providing high-quality pmma injection moulding manufacturing. As long as you want to customize/develop pmma injection moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.