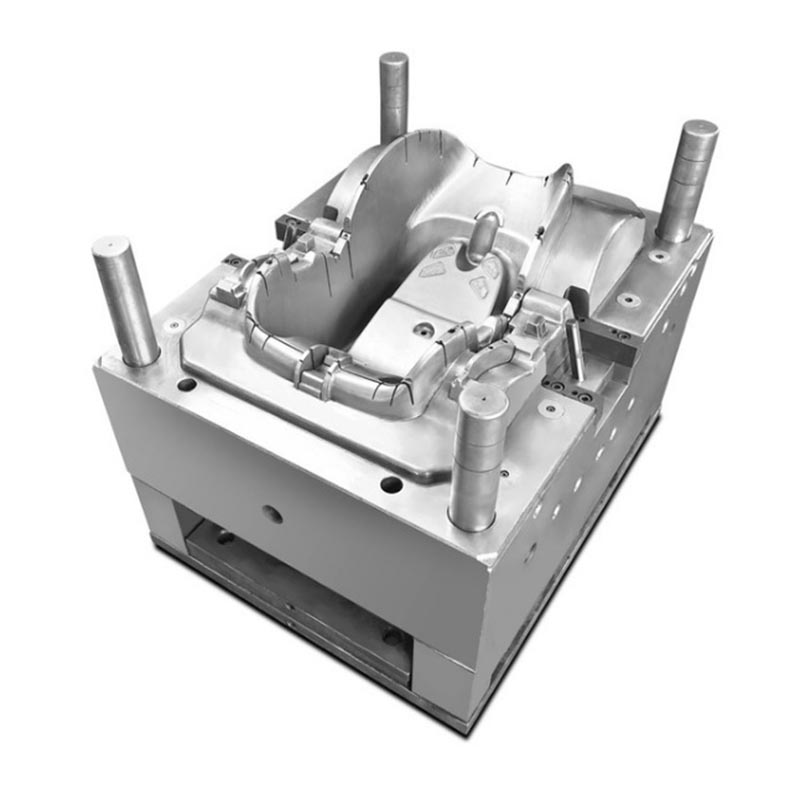

China Fishing Gear Mold Manufacturer, Supplier, Factory

Bear "Customer very first, Quality first" in mind, we work closely with our customers and supply them with efficient and professional services for Fishing Gear Mold, If you're interested in any of our products and services, make sure you don't be reluctant to call us. We've been wanting to reply you within 24 several hours just after receipt of your respective ask for and to generate mutual un-limited positive aspects and enterprise in in the vicinity of long run.

Fishing Gear Mold, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

Hot Products

Storage Box Molding

This is P&M from China, P&M is a supplier of plastic injection moulds, we would like to provide you with custom storage box molding service. We custom storage box molding, also help you making the dumbbell product. We provide you high-quality mold manufacturing mold services also the on-time transportation services. P&M is a mold manufacturing factory and a plastic product manufacturing factory, providing customers with one-stop services. Our factory has been in operation for over 10 years. We are Custom plastic mold maker, we can provide Plastic mold design and manufacturing. We have enough experience in injection molding, blow molding, rotational molding and die casting molding.Innovative Bowls With Multiple Functions For Kids

P&M is a manufacturer and supplier of Innovative Bowls With Multiple Functions For Kids in China. We have always placed the traceability of raw materials as our top priority, giving our customers peace of mind and parents who purchase children's meal bowls peace of mind. Our product not only has a price advantage, but its unique design and functionality make it highly competitive in the market. We look forward to becoming your long-term partner in China.Car Threshold Bar Equipment Molding

For customized car threshold bar equipment molding , NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Car threshold bar equipment includes: plastic shell, connecting parts, decorative strips, lighting devices, light lens etc. We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Feeding Bottle Molding

For feeding bottle molds, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional feeding bottle molding manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.Multifunctional Therapeutic Instrument Moulding

P&M has 17 years of Multifunctional therapeutic instrument Moulding technology. We provide professional mold customization services. We are a professional plastic mold manufacturer. We can use injection molding, blow molding, die casting and rotational molding.Glasses Frames Molding

As the professional manufacturer, we would like to provide you Glasses Frames Molding. Glasses are a very common item in daily life, whether in the streets and alleys of bustling cities or in the classrooms of peaceful campuses, people wearing various types of glasses can be seen everywhere. It is no longer just a tool for correcting vision, but also a symbol of fashion, cleverly blending practicality and aesthetics, showcasing the wearer's unique personality and style in different occasions. According to statistics, the number of myopic people worldwide continues to rise, and the market demand for glasses has also skyrocketed, becoming an indispensable part of people's lives.