- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

1 Liter Bucket Mould Injection

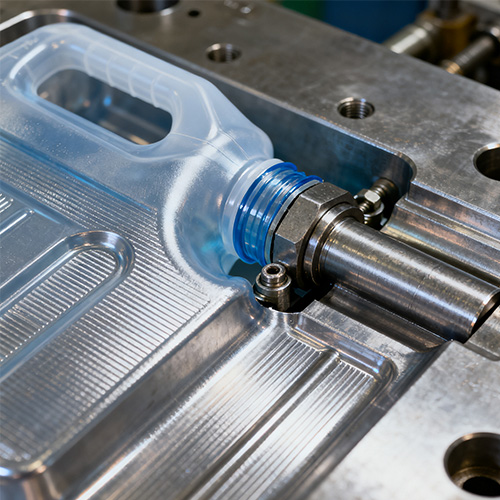

For 1 Liter Bucket Mould Injection, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

Send Inquiry

1 Liter Bucket Mould Injection refers to a small plastic barrel-shaped container with a volume of 1 liter (tolerance ±5%) produced through the injection molding process. It usually consists of a barrel body and a barrel lid (some styles include a handle), and is mainly used to hold liquids (such as cooking oil, sauces, daily chemical cleaners) or granular materials (such as coffee powder, grains). Its core feature is using the injection molding process to realize the integrated molding of the barrel body (no splicing gaps, strong leakage prevention), with a compact size (diameter usually 80-120mm, height 150-200mm) and light weight (30-50g), adapting to small-capacity storage and portability needs in home, catering, small business and other scenarios. Compared with traditional blow-molded 1-liter barrels, the barrel body produced by the injection molding process has higher rigidity, uniform wall thickness (deviation ≤0.2mm), and can integrate complex structures (such as anti-theft buckles, measurement scales), and is widely used in food contact and daily chemical packaging fields.

P&M 1 Liter Bucket Mould Injection Introduction

A、Core Characteristics of 1 Liter Bucket Mould Injection

1. High Sealing and Leakage Prevention

2. Food Contact Safety and Hygiene

3. Lightweight and Portability

4. Flexible Structure and Multi-Functional Integration

B、Production Process of 1 Liter Bucket Mould Injection

1. Product Design and Mold Development

(1) Product Design

Structural design: Draw a 3D model using CAD software (SolidWorks, AutoCAD), with a focus on designing the wall thickness distribution of the barrel (uniform 0.8-1.2mm, locally thickened to 1.5mm at the barrel mouth and bottom to enhance strength), sealing groove size (compatible with silicone sealing rings, gap ≤ 0.1mm), and connection structure between the handle and barrel (transition fillet R2mm to avoid stress concentration);

Simulation verification: Use CAE software (Moldflow) to simulate the injection filling process and optimize the gate position (usually set at the center of the barrel bottom to avoid surface gate marks); Analyze the cooling process and ensure that the cooling time for areas with uniform wall thickness is 15-20 seconds, and for areas with increased thickness, it is extended to 25-30 seconds to avoid shrinkage marks and deformation.

(2) Mold development

Mold material: The barrel mold is made of P20 pre hardened steel (for small and medium batch production) or H13 hot work mold steel (for large-scale production, with a service life of ≥ 300000 times), and the barrel cover mold is made of S136 stainless steel (with strong corrosion resistance and suitable for food contact grade products);

Mold cavity design: Multiple mold cavities (1 mold 8-16 cavities, symmetrically distributed in a circular shape) are used to ensure uniform filling of each cavity (filling time difference ≤ 0.3 seconds); Polish the inner wall of the barrel cavity to Ra ≤ 0.2 μ m to ensure a smooth surface of the barrel;

Cooling system: The barrel mold adopts a conformal cooling water circuit (arranged around the circumference of the barrel with a spacing of 15-20mm), and the barrel cover mold is equipped with a top pin cooling (to avoid shrinkage marks on the cover surface). The diameter of the cooling water circuit is 8-10mm to ensure cooling efficiency.

2. Raw Material Preparation and Injection Molding

(1) Raw material pretreatment

Material selection: Food grade PP (such as PP R370Y, melt index 10-15g/10min) or HDPE (such as HDPE 5000S, density 0.95g/cm ³) should be used for food contact grade barrels;

Drying treatment: PP material needs to be dried (temperature 80-90 ℃, time 2-3 hours, moisture content ≤ 0.05%), HDPE has low moisture absorption (moisture content ≤ 0.1% can be used directly), to avoid bubbles after injection molding;

Material modification: Add color masterbatch (such as white or transparent color, with an addition ratio of 1% -2%) to ensure uniform color (color difference Δ E ≤ 1.5); Toxic additives are prohibited in food grade barrels, and only antioxidants (0.1% -0.2%, such as 1010 antioxidant) can be added to delay aging.

(2) Injection molding

Barrel body injection molding: using a horizontal injection molding machine (locking force of 150-250 tons, injection volume of 100-200g), process parameters: PP material temperature of 180-220 ℃ (front section 180-190 ℃, middle section 190-210 ℃, rear section 210-220 ℃), injection pressure of 60-80MPa, holding pressure of 40-60MPa, holding time of 8-12 seconds, cooling time of 15-20 seconds;

Barrel lid injection molding: PP material temperature 190-220 ℃, injection pressure 70-90MPa, holding time 5-8 seconds, cooling time 10-15 seconds; It is necessary to focus on controlling the size of anti-theft buckles and sealing grooves to ensure accuracy (tolerance ± 0.05mm);

Demoulding and retrieval: Using a robotic arm for automatic retrieval (to avoid manual contamination), during demoulding, the ejector pin is used in conjunction with the demoulding template to ensure that the barrel body is free from scratches and deformations.

3. Post-Processing and Assembly

P&M 1 Liter Bucket Mould Injection(Specification)

|

Mould Name |

1 Liter Bucket Mould Injection |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M 1 Liter Bucket Mould Injection Feature And Application

1. Food Contact Scenario

Core Requirements: Hygienic safety, no odor, food corrosion resistance, adapting to scenarios such as cooking oil, sauces, and dairy products.

Product Features:

Materials use food-grade PP (e.g., PP R370Y) or HDPE (e.g., HDPE 5000S), certified by FDA and GB 4806.7-2016, with migration ≤5mg/kg;

The inner wall of the barrel body is mirror-polished (Ra≤0.4μm) with no dead-angle residue; the barrel lid is equipped with an aluminum foil sealing film (heat-sealing temperature 120-140℃), maintaining sterility before opening to avoid transportation pollution;

Some sauce barrels (e.g., broad bean paste, chili sauce) are designed with a wide mouth (diameter ≥100mm) for easy spoon access, and the barrel mouth edge is rounded (R2mm) to prevent scratches.

2. Daily Chemical Cleaning Scenario

Core requirements: resistant to chemical corrosion, leak proof, easy to stack, suitable for liquids such as dishwashing detergent, laundry detergent, disinfectant, etc.

Product features:

The material is made of chemical resistant HDPE (which can withstand acidic and alkaline cleaning agents with pH 2-12), and the wall thickness of the barrel is 1.0-1.2mm (to enhance drop resistance);

The bucket lid is designed with a press type liquid outlet (with a built-in silicone valve core, which releases liquid when pressed and automatically seals when released) to prevent spillage during pouring; Add anti UV agents (0.5% -1%) to some disinfectant buckets to prevent material aging during outdoor storage;

The bottom adopts a reinforced rib design (with a spacing of 15mm and a thickness of 1.5mm), which can stack 8-10 layers and save storage space for supermarkets.

3. Industrial Sample and Reagent Scenario

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.