- Core Customization Service

- Health Care

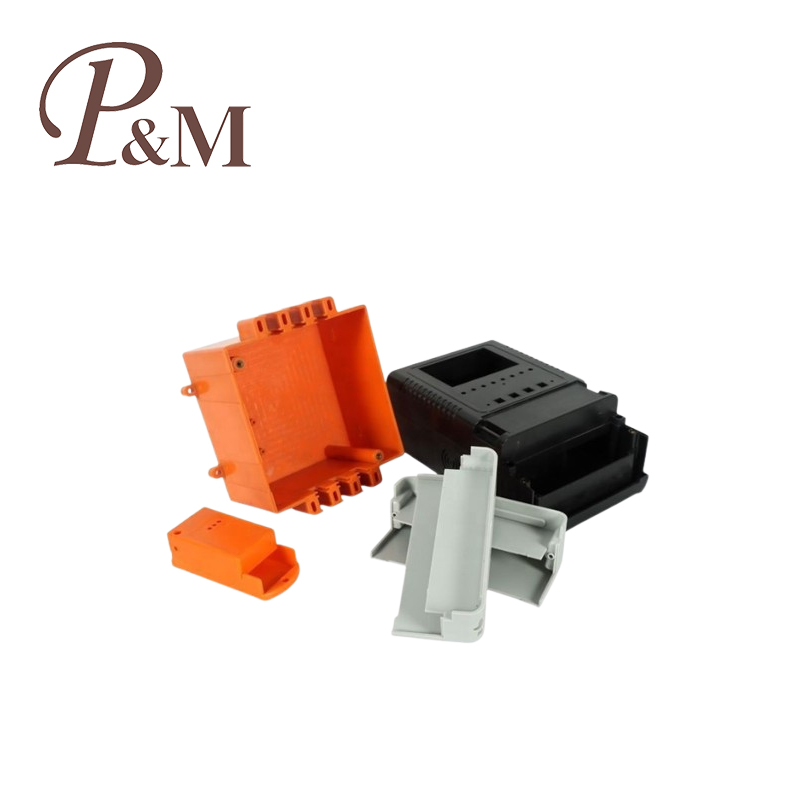

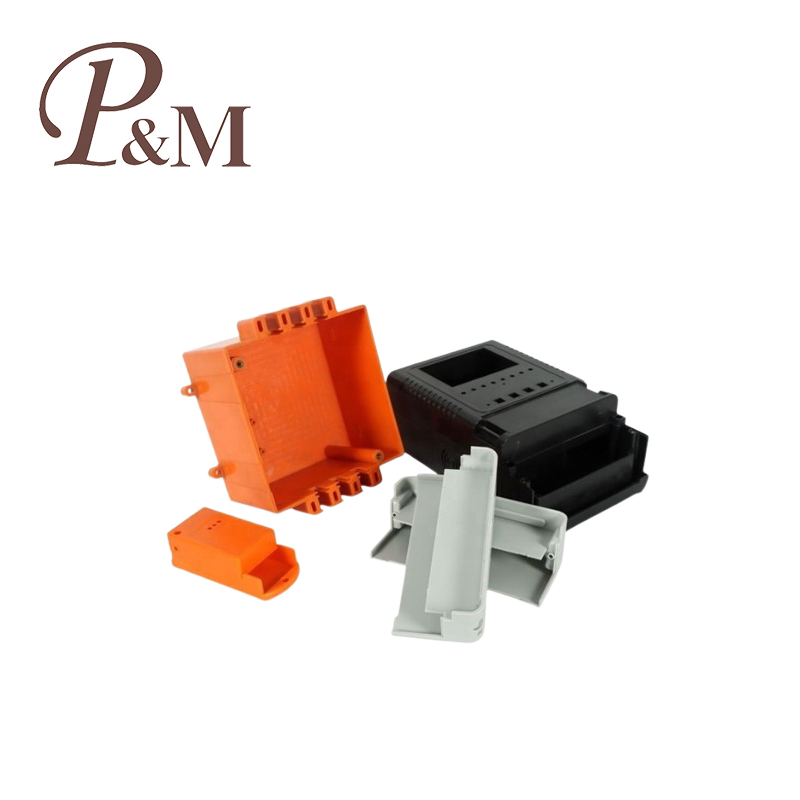

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

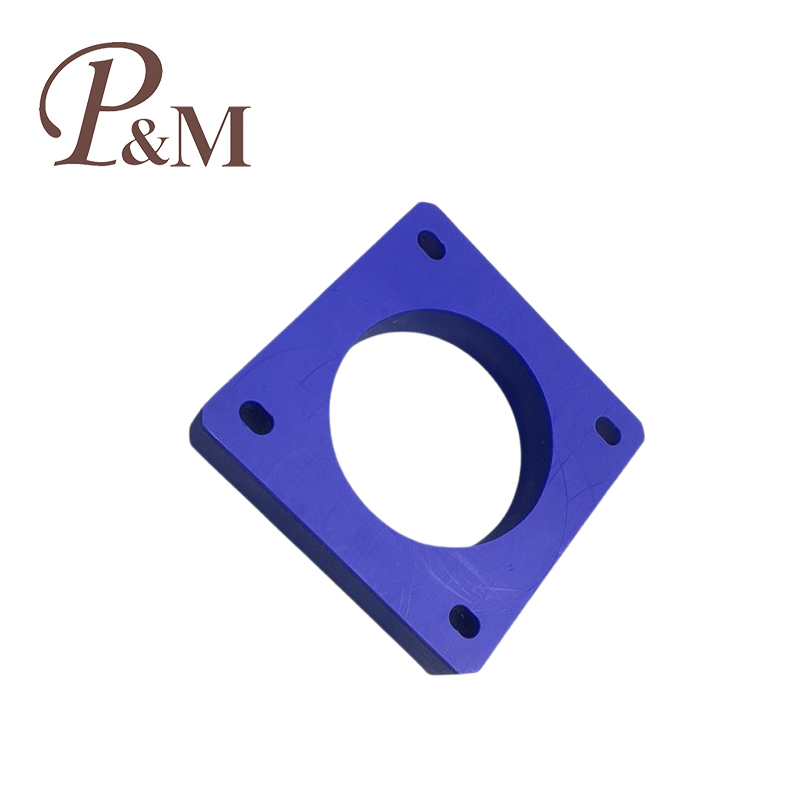

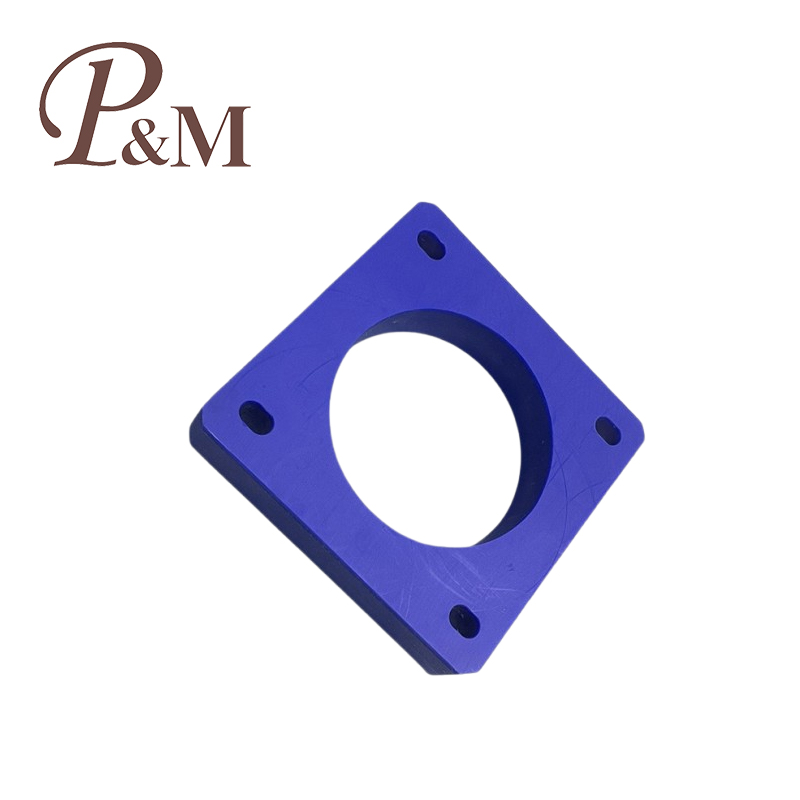

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Acrylic (PMMA) molded components

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Custom Injection molded parts. We have ISO 9001 certificates. We provide professional Acrylic (PMMA) molded components and we are professional custom Acrylic (PMMA) molded components. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.

Send Inquiry

We are a precision manufacturer of custom Acrylic (PMMA) molded components, specializing in parts where exceptional clarity, brilliant aesthetics, and superior weatherability are paramount. As your dedicated manufacturing partner, we combine expert material handling with meticulous processing to transform PMMA into high-performance components and sub-assemblies. We are not distributors; we are engineers and producers who manage the entire process from optical-grade tooling to controlled production and final assembly.

Our Service: Precision Acrylic Components & Integrated Assemblies

We manufacture the crystal-clear, durable plastic parts that define product quality and functionality. Our core service is producing custom PMMA components that meet stringent optical and cosmetic standards. We add significant value through secondary services such as precision machining, polishing, anti-scratch or anti-reflective coating, and assembly with light sources or other components, delivering ready-to-integrate optical sub-systems.

Custom Design for Optical Performance & Durability

Designing for PMMA requires a focus on managing its inherent brittleness, high shrinkage, and optical requirements. We engineer every part for clarity, strength, and manufacturability:

Wall Thickness & Uniformity: Critically important. We maintain consistent wall thickness to prevent distortion, visible sink marks, and internal stress that can compromise optical quality or lead to stress cracking.

Radii & Transitions: Generous radii are incorporated at all corners and intersections to distribute stress, reduce crack initiation points, and facilitate smooth material flow for better clarity.

Ribs & Bosses: Used sparingly and designed with careful attention to thickness (typically ≤ 60% of adjacent wall) to minimize sink marks on visible surfaces. Bosses are often designed with hollow cores to maintain uniformity.

Draft Angles & Ejection: Sufficient draft is applied to all vertical surfaces to ensure scratch-free part ejection from the polished mold, which is essential for preserving optical surfaces.

Gate & Flow Design: Strategically placed (often submarine or tab gates) to direct weld lines to non-critical areas and ensure a smooth, laminar fill that preserves clarity and minimizes optical distortion.

PMMA Material Science: Selecting for Clarity and Application

Acrylic is prized for its glass-like properties. We guide you to the optimal grade for performance:

General Purpose PMMA: Offers excellent optical clarity (92% light transmission), high gloss, and good UV resistance. Ideal for lenses, light guides, nameplates, and decorative trim.

Impact-Modified PMMA: Incorporates additives to improve toughness and chip resistance while retaining much of its clarity. Used for automotive lighting lenses (tail lights), bathtub enclosures, and protective covers.

Medical & FDA-Compliant Grades: Formulated for biocompatibility, meeting USP Class VI and ISO 10993 standards. Used for fluid reservoirs, diagnostic device housings, and clear medical components.

Extruded vs. Cast vs. Molded Grades: We specialize in injection molding grades, which offer the best balance of flow properties and cost-effectiveness for complex, medium-to-high-volume components, compared to the superior optical quality but lower shape complexity of cast acrylic.

Key PMMA Properties & Applications:

Optical Clarity & Light Transmission: Superior to polycarbonate and glass in clarity, with exceptional light-guiding properties for LED lenses, light pipes, and optical diffusers.

Excellent Weatherability & UV Stability: Resists yellowing and degradation from prolonged sunlight exposure, making it the premier choice for outdoor signs, automotive exterior trim, and solar panels.

High Surface Hardness & Gloss: Provides good scratch resistance and a brilliant, lasting finish straight from the mold, reducing post-processing for many applications.

Good Chemical Resistance: Withstands many dilute acids, alkalis, and alcohols, suitable for laboratory equipment and cosmetic packaging.

The Precision PMMA Molding Process: Mastering Clarity and Stress

Molding optical-quality acrylic is a discipline that demands extreme control over temperature, pressure, and material purity.

Critical Pre-Process: Drying. PMMA is hygroscopic. Mandatory, thorough drying is required to prevent moisture-related defects like cloudiness (splay), bubbles, and reduced molecular weight, which directly impact strength and clarity.

Process Specifics: We utilize moderate to high melt temperatures and slow to moderate injection speeds. This allows the viscous melt to fill the cavity in a laminar flow, preventing shear-induced stress and veining. Precise, high mold temperatures (often 70-90°C) are vital. This reduces internal stress, improves surface replication of the polished mold, and enhances the gloss and optical properties of the final part.

Tooling Excellence: We use high-polish, corrosion-resistant mold steels (e.g., Stainless Steel 420) to achieve the required mirror finish and prevent contamination that could mar the part surface.

Key Advantages of Our PMMA Molding:

Minimized Internal Stress & Optical Distortion: Our controlled process yields parts with exceptionally low molded-in stress, which is critical for maintaining optical purity and preventing stress cracking during secondary operations or in service.

Superior Aesthetic & Surface Quality: The combination of polished tooling, precise temperature control, and clean processing produces parts with outstanding gloss, clarity, and freedom from defects like flow lines or sink marks.

Consistent Optical Performance: Batch-to-batch consistency in light transmission and refractive index is achieved through strict material and process controls.

Ability to Mold Complex Optical Shapes: We can produce intricate light-guiding features, micro-lens arrays, and detailed aesthetic geometries that are impossible to achieve with machining or casting at scale.

Why Partner with Us for Acrylic Components?

Our differentiation is our dedicated focus on transparent and cosmetic polymers. We understand the science of achieving and preserving clarity. We provide essential Design for Manufacturability (DFM) analysis focused on eliminating optical defects and stress concentrations. From prototyping to production, we manage the process with a cleanroom-level mindset to ensure every component meets the highest aesthetic and functional standards.

Choose us for your PMMA parts when your application demands brilliance, durability, and precision. We deliver more than clear plastic; we provide engineered optical solutions that enhance light, perception, and product value.

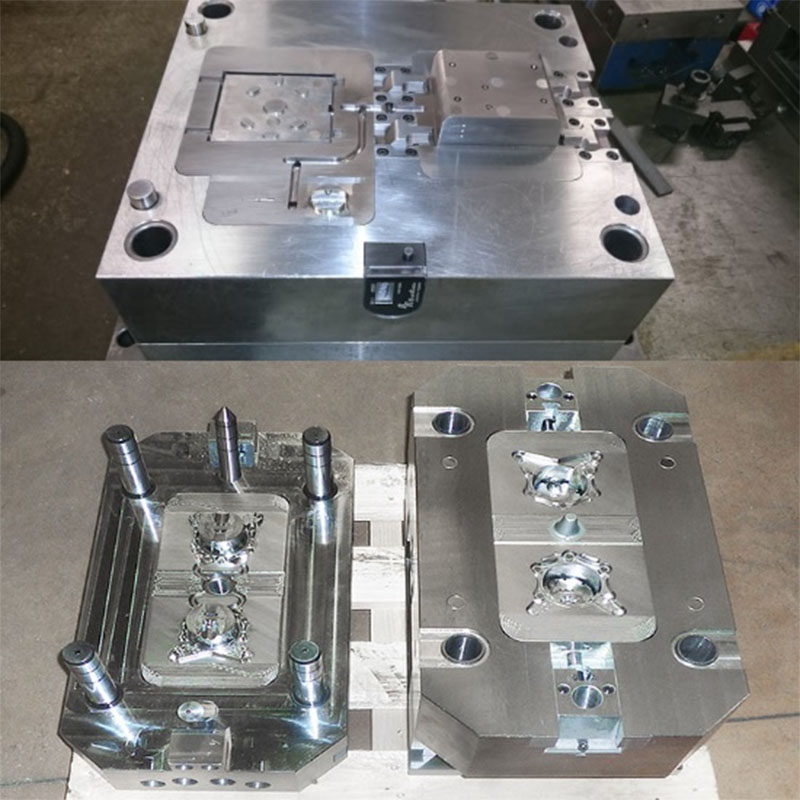

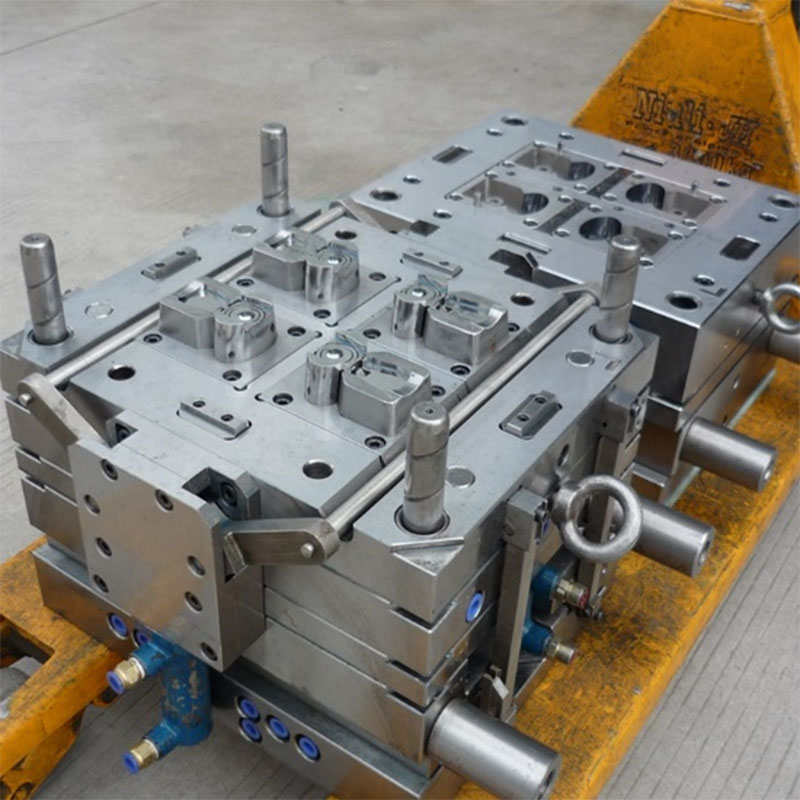

We are plastic mold maker and can provide custom mold service, we can make injection molds, blow molds, rotational molds and die-casting molds.

For custom injection molds, we can provide professional custom injection molding services. Usually Plastic injection mold manufacturing Molding are manufactured using injection molding technology. The mold materials for injection molds can be chosen from P20, 718, S136, H13 and so on. The mold material reflects the mold life and product material requirements.

For parts that require blow molding production, we can also provide professional custom blow molding services.

|

Product Name |

Acrylic (PMMA) molded components

|

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic injection mold manufacturing Injection Mould making

1.We communicate product design according to samples/drawings and your requirements.

2.After the product design is confirmed, we carry out the mold design, we provide all kinds of injection molds, blow molds, silicone molds, die-casting molds services.

3.Material procurement, steel cutting and mold basic tools.

4.Mold assembly

5.Mold inspection, tracking and controlling mold processing.

6. We will inform you the date of mold trial and send you the sample inspection report and injection parameters together with the sample.

7.Your instruction and confirmation of shipment.

8.Prepare the mold before packing.

Plastic injection mold manufacturing molding Specification

1. Professional manufacturer, design, production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Transaction process:

Mold testing:

Once the mold is complete, I do a mold test. It usually takes about 3-5 days to complete. We need to assemble the mold, adjust the pressure data of the machine, and try production. We need to check whether there are problems during the normal production of the mold and make modifications.

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

Factory

Video-1: (Factory Video)

Video-2: (Injection Molding)

Video-3: (Blow molding)

Video-4: (Blow molding)

Video-5: (Roll molding)

Customer satisfaction is our most important goal. We focus on communication and cooperation with our customers, always pay attention to their needs and provide quick response and quality customer service. Our injection production mold factory is committed to establishing long-term relationships and ensuring that our customers receive the best after-sales service during the purchase and use of our products, and we will definitely do our best to solve any problems for our customers.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us?

Mould,Plastic Product, Metal Product,Dental Product,CNC machining.

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6. What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.