- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Custom chopper bike parts moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize custom chopper bike parts moulding. We provide professional customized custom chopper bike parts moulding services, and we are a professional custom chopper bike parts moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing custom chopper bike parts moulding, our factory can provide one-stop service. We have design and production capabilities related to custom chopper bike parts moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized custom chopper bike parts moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For custom chopper bike parts moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

The core of customizing "helier-grade" bicycle parts lies in integrating the aviation industry's pursuit of ultimate performance, lightweight and complex structures into the design and manufacturing of bicycles. The entire process revolves around this core contradiction and is a highly integrated project from design to manufacturing.

In-depth analysis of Core processes

The realization of "helicopter bicycle" parts mainly involves the following two technical routes:

Route One: Aviation Derivative Route (Performance First

The inspiration for this route directly comes from aviation manufacturing, such as the famous "Airbike", which is made of a mixture of nylon, carbon fiber and metal powder and formed in one piece through layering manufacturing (3D printing).

Core process: 3D design → Additive manufacturing (such as laser sintering) → possible post-curing/sintering → Precision machining (such as CNC partial finishing) → assembly.

Advantages: It offers an extremely high degree of design freedom, enabling the creation of topological optimization structures that are unachievable through traditional methods (such as bionic skeletons), and achieving the best stiffness/weight ratio. The product is integrally formed, with a very small number of parts and an extremely strong structural integrity.

Challenges: The manufacturing cost is extremely high, the production speed is slow, and it is more suitable for prototypes, small-batch customization or top-limited edition products. The anisotropy of the material is significant, and the requirements for process control are strict.

Route Two: Advanced Injection Molding Route (Balancing Efficiency and Performance)

This is currently the mainstream direction for high-performance bicycle components (such as frames and handlebars) to enter mass production. It makes a leap forward on the basis of traditional plastic molding by integrating multiple cutting-edge injection molding technologies.

Core process: Taking the handlebar as an example, its core is the "one-step" manufacturing method: Continuous carbon fiber reinforced Tape (UD Tape) is pre-placed in the mold at the key force-bearing parts → Engineering plastics containing glass fibers (such as nylon 6) are injected → at the same time, gas is injected using the "fluid core melting technology" to form a hollow complex inner cavity and push the molten plastic back to the machine for recovery → the mold is cooled and opened to obtain the finished product.

Advantage: An outstanding balance between efficiency and performance. The production cycle can be as short as about 60 seconds, making it suitable for larger quantities. Through local reinforcement and hollow thin-walled design, it achieves excellent rigidity and fatigue resistance while reducing weight (about 15% lighter than aluminum). The design freedom is also much higher than that of traditional metal processing.

Challenge: The initial investment in molds and specialized equipment (such as rodless injection molding machines) is huge. The process development is complex and requires a high degree of coordination among materials, molds and automation.

⚙️ How to choose technology

Key suggestions and action steps

Clarify requirements and budget: This is the first step in decision-making. You need to clarify whether the parts are for verifying concepts, participating in competitions, or preparing for commercial sales? What are the target annual output and unit cost budget?

Seeking cross-industry partners: No matter which route is chosen, it is necessary to look for suppliers with backgrounds in aerospace, automotive or top sports equipment manufacturing. They understand the culture of "performance first" and the corresponding quality control system.

Conduct early technical consultation: With a preliminary 3D design model, conduct a technical feasibility review with potential suppliers. They can offer valuable advice on material selection, process details, cost estimation and design optimization (DFM).

Emphasize testing and certification: Helier-grade parts mean ultimate reliability. The budget must include strict testing procedures, such as CT scans (to inspect the internal structure), fatigue tests (simulating tens of thousands of riding loads), and destructive tests, to ensure compliance with or exceeding relevant ISO standards.

If you could share more specific ideas about this part (for example, is it the frame, crank or other components?) What are the target weight and stiffness? What is the expected production scale?" I can offer you a more targeted analysis.

We are a custom chopper bike parts moulding manufacturer, providing high-quality custom chopper bike parts moulding manufacturing. As long as you want to customize/develop custom chopper bike parts moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

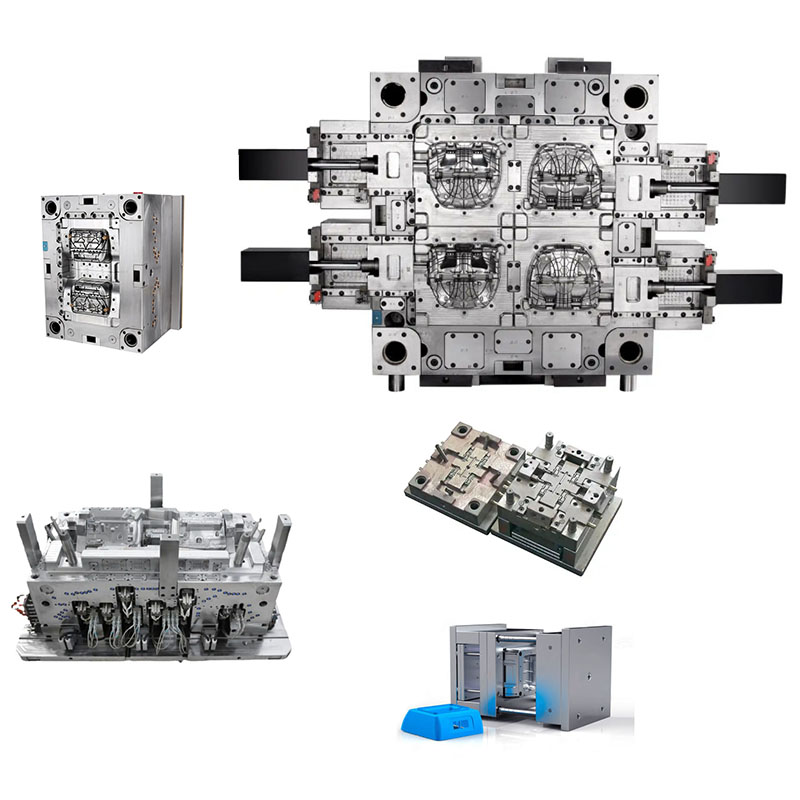

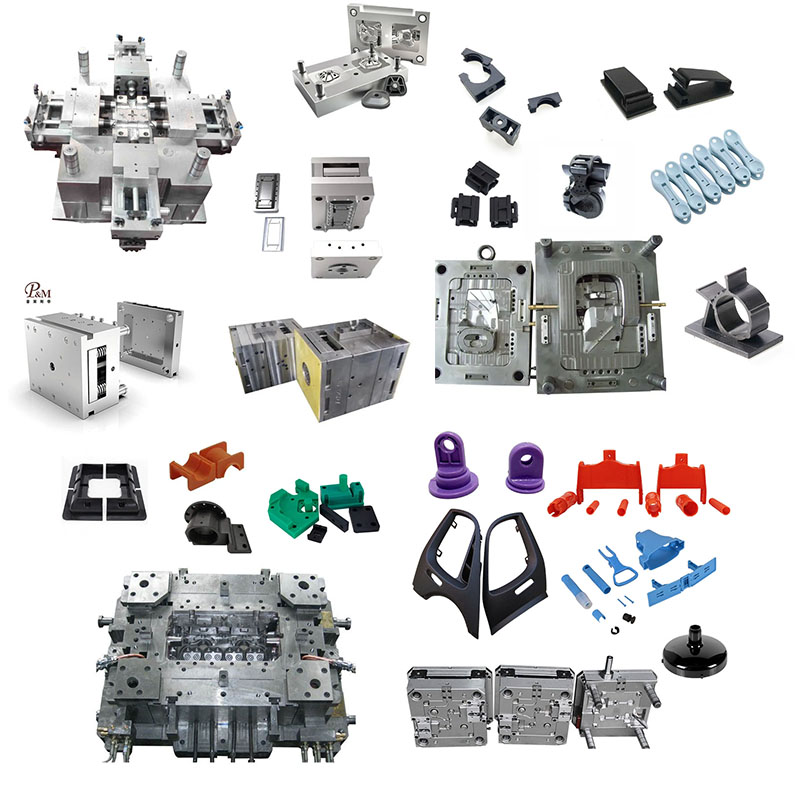

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.