- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Custom injection plastic clip moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize custom injection plastic clip moulding. We provide professional customized custom injection plastic clip moulding services, and we are a professional custom injection plastic clip moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing custom injection plastic clip moulding, our factory can provide one-stop service. We have design and production capabilities related to custom injection plastic clip moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized custom injection plastic clip moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For custom injection plastic clip moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

The molding process for custom injection-molded plastic clips integrates structural design, precision molds, and materials science. Although small, plastic clips demand high functionality (such as clamping force and durability), feel, and appearance.

The following is a detailed molding process for custom injection-molded plastic clips, highlighting their core functional components.

The Complete Process for Custom Injection Molded Plastic Clips

Phase 1: Requirements Analysis and Design (Design & Engineering)

This is the soul of a custom project and determines the success or failure of the final product.

Defining Requirements:

Functionality: Clamping force requirements, opening stroke, and service life (number of openings and closings).

Environmental: Chemical resistance, high and low temperature resistance (e.g., dishwasher compatibility), and outdoor use (UV resistance required).

Appearance: Color, surface texture (gloss, matte, textured), and logo inclusion.

Regulations: Food contact (FDA standards) and compliance with specific industry standards.

Structural Design (DFM - Design and Manufacturing Feasibility):

Hinge design: The core of the plastic clip. Living hinge designs are typically used, leveraging the fatigue resistance of PP/PE materials and achieving numerous bends without breaking through localized thinning.

Clip and serrations: Designed with anti-slip serrations and a reliable clip structure to ensure strong clamping force. Stress analysis is required to prevent stress concentration that can lead to breakage.

Uniform wall thickness: Ensure uniform shrinkage to prevent shrinkage and warping.

Mold draft angle: Adequate draft angle is essential for easy demolding, especially for deep cavities and serrations.

Material Selection:

Polypropylene (PP): The most commonly used choice. Its excellent toughness and fatigue resistance make it an ideal material for living hinges at a low cost.

Polyethylene (PE): Softer and more chemically resistant, but slightly less rigid.

Nylon (PA): Used for high-end clamps requiring higher strength, rigidity, and wear resistance, such as heavy-duty industrial clamps.

Additives: Masterbatch, UV inhibitors, toughening agents, etc. may be added to meet specific requirements.

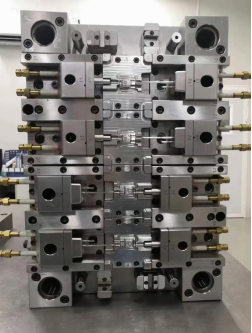

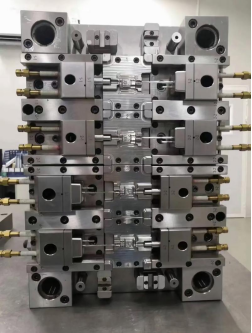

Phase Two: Precision Mold Design & Manufacturing

The mold is the cornerstone of the design. Plastic clamp molds are typically multi-cavity, high-speed molds.

Cavity Layout: Use a multi-cavity layout (e.g., 32-cavity or 64-cavity) to improve production efficiency.

Gating System:

Hot runner: Highly recommended. It saves raw materials, eliminates the need for a handle, shortens cycle time, and enables fully automated production. A needle-valve hot nozzle ensures a beautiful gate.

Cold runner: For extremely small batches or extremely simple designs, a three-plate mold with point gates can be used.

Ejector System:

Ejectors must be located on non-working surfaces and in locations with high structural strength (such as on the frame or ribs) to prevent whitening or deformation.

For clamps with teeth, special flat ejectors or sleeve ejectors may be required.

Cooling System: The design must be efficient and uniform to ensure short cycle times and stable product dimensions.

Venting System: Provide venting slots at the final melt filling point to prevent trapped air, which can cause burning or underfill.

Stage 3: Injection Molding Process

The goal of process tuning is to ensure hinge functionality and dimensional accuracy.

Material Processing: PP/PE materials require drying at 80°C for 1-2 hours. Although they are not highly absorbent, drying ensures optimal surface quality.

Injection Molding Parameters:

High Mold Temperature: Using a higher mold temperature (approximately 50-70°C for PP materials) helps improve melt flow, reproduce mold surface details, and reduce molecular orientation in the hinge area, thereby increasing the hinge's fatigue life.

Medium-to-high-speed injection: Ensures rapid cavity filling.

Sufficient holding pressure and cooling time: Ensures full product formation and prevents dimensional defects or deformation caused by excessive shrinkage.

Stage 4: Post-Processing & QC

Post-Processing:

De-gating: De-gating is performed during automated part removal by the robot or for post-processing trimming and smoothing.

Hinge Bending Pre-treatment: For some designs, several manual or mechanical bending cycles are required after the initial mold opening to "activate" the hinge and achieve optimal performance.

**Rigorous Quality Inspection (Functional Testing is Key)**:

Appearance Inspection: Check for shrinkage, flash, missing material, color difference, etc.

Dimensional Inspection: Use calipers and 2D imagers to inspect key dimensions such as opening size and arm length.

Functional Testing (Core):

Clamping Force Test: Use a dynamometer to test whether the clamp's holding force meets the specified standards.

Life Test (Fatigue Test): Use specialized equipment to test sample samples for tens or even hundreds of thousands of opening and closing cycles, and calculate the damage rate. This is the most critical step in verifying hinge design.

Handle Test: Manually evaluate whether the opening and closing feel is smooth and the force applied is appropriate.

We are a custom injection plastic clip moulding manufacturer, providing high-quality custom injection plastic clip moulding manufacturing. As long as you want to customize/develop custom injection plastic clip moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.