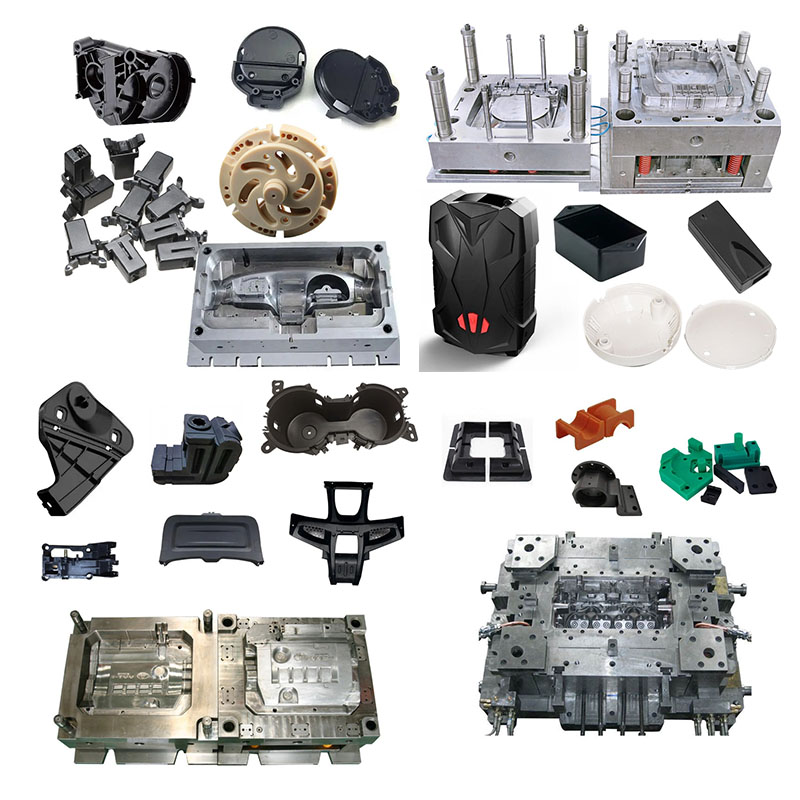

- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Custom pvc parts moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize custom pvc parts moulding. We provide professional customized custom pvc parts moulding services, and we are a professional custom pvc parts moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing custom pvc parts moulding, our factory can provide one-stop service. We have design and production capabilities related to custom pvc parts moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized custom pvc parts moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For custom pvc parts moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

The injection molding of custom PVC (polyvinyl chloride) parts is a precise process that "dances in shackles". The core challenge lies in balancing the heat sensitivity (easy decomposition) and processing fluidity of PVC, while also addressing the corrosiveness of its decomposition products.

The following are the core points of custom PVC parts injection molding. This is a practical guide focused on "how to do it safely and stably".

Key points of custom PVC parts injection molding

Key Point One: Materials and Formulas - Control risks from the source

PVC is a formula-based material, and its processability is entirely dependent on additives.

Specialized injection-grade PVC material: Only injection-specific PVC resin grades and matching composite materials must be selected, rather than general-purpose PVC.

Core additive

Heat stabilizer: Of Paramount importance. It must be added in sufficient quantities to broaden the processing temperature window (typical range 160-190℃) and prevent the decomposition and generation of HCl gas during processing. According to environmental protection requirements, calcium-zinc stabilizers (environmentally friendly and lead-free) or traditional lead salt stabilizers can be selected.

Lubricant: The internal and external lubricants should be balanced to ensure uniform plasticization and smooth demolding.

Processing AIDS: Enhance melt strength and surface gloss.

Pretreatment: Even if composite materials are used, it is recommended to dry them at 80-90℃ for 1-2 hours to remove trace amounts of moisture.

Key Point Two: Specialized equipment and anti-corrosion molds - Hardware is the foundation

This is the uncompromising bottom line of PVC injection molding.

Requirements for injection molding machines

Special screw: "PVC special screw" must be used. Its characteristics are a small compression ratio (about 1.8-2.0), a short length-to-diameter ratio, and deep screw grooves to minimize shear heat to the greatest extent.

Anti-corrosion barrel: The inner wall of the barrel and the screw should undergo surface hardening anti-corrosion treatment (such as nitriding).

Open nozzle: Avoid using self-locking nozzles to prevent material retention and decomposition.

Mold requirements

Steel and coating: The parts of the cavity, flow channel, etc. that come into contact with the melt must be made of corrosion-resistant stainless steel or treated with hard chromium plating.

Runner and gate: Design a short and thick runner. The gate size must be large enough (such as fan-shaped gates or direct gates) to reduce flow resistance. It is strictly prohibited to use small point gates.

Strong exhaust: It is necessary to set up sufficient and deep exhaust channels (with a depth of 0.03-0.05mm), which is the key to preventing the product from burning.

Cooling: Design an effective cooling waterway to prevent the material from staying in the mold for too long.

Key Point Three: Injection Molding Process - the golden rule of "low temperature, low speed, and low shear"

The core of the process is to avoid local overheating.

Strict temperature control

Barrel temperature: Strict segmented control is adopted, gradually increasing slightly from the back to the front.

Suggested range: Rear section 130-150℃ → Middle section 150-170℃ → front section 165-180℃ → Nozzle 170-185℃.

Core principle: Use the lowest possible temperature under the premise of ensuring filling. The temperature indicated by the instrument should not exceed 190℃.

Gentle pressure and speed

Injection speed: Medium and low speed injection is adopted. High speed generates shearing heat, causing the material to decompose (resulting in yellow lines or black spots on the product).

Back pressure and screw speed: The use of low back pressure and low speed is also aimed at reducing shear heat and frictional heat.

Mold temperature: Controlled at 40-60℃. It helps to stabilize the molding and reduce internal stress.

Crucial production specifications

Cleaning procedure: Before the machine stops or when switching to produce other materials, the PVC in the barrel must be thoroughly replaced with cleaning materials such AS PS, PP or AS to prevent its retention and decomposition.

"Uninterrupted" production: If planned downtime exceeds 15 to 30 minutes, emptying and cleaning should also be considered.

Key Point Four: Quality Inspection and Countermeasures for Common Problems

Key appearance inspection

Yellowish-brown stripes/black dots: A clear signal of material decomposition. It is necessary to check whether the temperature is too high, whether the screw speed is too fast, and whether there are any dead corners for retention.

Silver streaks: This might be due to damp raw materials or excessive lubricant.

Charring: Caused by trapped gas, it is necessary to enhance the exhaust of the mold.

Performance test

Thermal stability test: Place the product in an oven and observe its color change time to verify the stability of the formula.

Precipitation test (for soft PVC) : Check whether plasticizers and other substances have migrated to the surface.

Action list as a professional supplier

Prove to customers that you can handle PVC

Hardware display: "We have injection molding machines equipped with PVC-specific screws and chrome-plated barrels, as well as hard-chrome-plated anti-corrosion molds."

Clarify the process: "We adhere to the 'three lows' process standards and have a strict SOP for shutdown cleaning to ensure safe and stable production."

We can recommend and test the appropriate calcium-zinc stabilizer formula based on your environmental protection requirements (such as lead-free)

We are a custom pvc parts moulding manufacturer, providing high-quality custom pvc parts moulding manufacturing. As long as you want to customize/develop custom pvc parts moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.