- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Custom Spare Parts Molding

In the dynamic landscape of manufacturing, Custom Spare Parts Molding stands as a cornerstone technology that bridges the gap between standardized components and the unique needs of diverse industries. As a professional injection mold manufacturer, P&M has long recognized the pivotal role of Custom Spare Parts Molding in enhancing operational efficiency and product reliability for our clients. Custom Spare Parts Molding is not merely a production process; it is a tailored solution that adapts to the specific dimensions, materials, and performance requirements of each application, ensuring that spare parts fit seamlessly and function optimally. What sets P&M apart in the realm of Custom Spare Parts Molding is our unwavering commitment to precision and client-centricity. We leverage decades of experience to transform client specifications into high-quality molded parts, making Custom Spare Parts Molding a core competency that drives our success and earns the trust of clients worldwide. Whether it is for automotive, electronics, or industrial machinery sectors, our Custom Spare Parts Molding services are designed to deliver consistency and durability, addressing the critical need for reliable spare parts that minimize downtime and maintenance costs.

Send Inquiry

For Custom Spare Parts Molding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 12 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

P&M Custom Spare Parts Molding Introduction

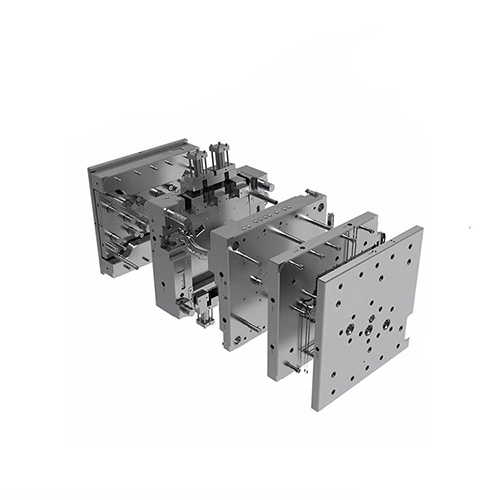

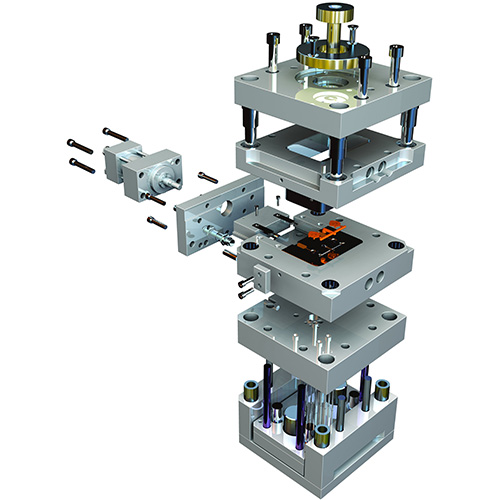

Custom Spare Parts Molding, at its essence, is an injection molding process specialized in creating non-standard spare parts that are engineered to meet the exact requirements of a particular product or machinery. Unlike mass-produced standard parts, which often require modifications to fit specific applications, Custom Spare Parts Molding starts with a deep understanding of the client’s unique needs—from material selection to dimensional accuracy, and from performance expectations to environmental adaptability. As a leading injection mold manufacturer, P&M has refined the Custom Spare Parts Molding process to be both efficient and precise, integrating advanced design software and state-of-the-art molding equipment to ensure every part meets the highest standards. The journey of Custom Spare Parts Molding at P&M begins with a comprehensive consultation with the client. Our team of experienced engineers works closely with clients to gather detailed information about the application, including the operating conditions of the machinery, the load-bearing requirements of the part, and any regulatory or industry-specific standards that must be adhered to. This collaborative approach ensures that the Custom Spare Parts Molding solution is not only technically feasible but also aligned with the client’s operational and budgetary goals. Following the consultation, we move to the design phase, where we use 3D modeling software to create a detailed prototype of the spare part. This prototype allows clients to visualize the final product and provide feedback, which we incorporate into the design before moving to mold fabrication. The mold is the heart of Custom Spare Parts Molding, and at P&M, we craft each mold with meticulous attention to detail, using high-grade steel and advanced machining techniques to ensure durability and precision. Once the mold is ready, we proceed to the injection molding phase, where we use premium materials—selected based on the part’s intended use—to produce the custom spare parts. Throughout this process, we implement strict quality control measures, from material testing to dimensional inspection, to ensure that every part from our Custom Spare Parts Molding line meets the client’s specifications. What makes P&M’s Custom Spare Parts Molding service stand out is our ability to handle both small-batch and large-volume orders with equal efficiency. We understand that clients may need a small number of critical spare parts for emergency repairs or large quantities for long-term inventory management, and our flexible production lines are designed to accommodate these varying needs. Additionally, our in-house mold design and fabrication capabilities eliminate the need for third-party vendors, reducing lead times and ensuring greater control over the quality of the Custom Spare Parts Molding process. This vertical integration is a key advantage that allows us to deliver custom spare parts faster than many competitors, helping clients minimize downtime and maintain continuous operations. Another critical aspect of Custom Spare Parts Molding at P&M is our commitment to sustainability. We prioritize the use of eco-friendly materials and implement energy-efficient practices in our molding process, reducing the environmental impact of production without compromising on quality. This focus on sustainability not only aligns with global environmental goals but also helps our clients meet their own sustainability targets, adding value to the Custom Spare Parts Molding solutions we provide.

P&M Custom Spare Parts Molding(Specification)

|

Mould Name |

Custom Spare Parts Molding |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Custom Spare Parts Molding Feature And Application

Custom Spare Parts Molding boasts a unique set of features that make it indispensable across a wide range of industries, and at P&M, we have harnessed these features to deliver tailored solutions that address the specific challenges of each sector. One of the most prominent features of Custom Spare Parts Molding is its exceptional precision. Thanks to advanced mold design and high-precision injection molding equipment, we can achieve tight tolerances—often as low as ±0.005mm—ensuring that custom spare parts fit perfectly with existing components. This precision is critical in industries where even the smallest deviation can lead to machinery failure or product defects, and it is a hallmark of P&M’s Custom Spare Parts Molding service. Another key feature of Custom Spare Parts Molding is material versatility. Unlike standard parts that are limited to a few common materials, Custom Spare Parts Molding allows for the use of a wide range of polymers, including engineering plastics like ABS, polycarbonate, nylon, and PEEK, as well as composite materials reinforced with glass fiber or carbon fiber. At P&M, our material experts work with clients to select the optimal material based on the part’s intended use—whether it requires high strength, chemical resistance, heat resistance, or flexibility. This material versatility ensures that our Custom Spare Parts Molding solutions are durable and reliable in even the harshest operating environments. Consistency is another vital feature of Custom Spare Parts Molding at P&M. Our automated production lines and strict quality control protocols ensure that every part produced is identical in size, shape, and performance. This consistency is essential for clients who rely on spare parts to maintain uniform performance across their machinery or products, and it eliminates the risk of mismatched parts that can lead to operational inefficiencies. Additionally, Custom Spare Parts Molding offers excellent cost-effectiveness for both small and large orders. While the initial mold fabrication may involve an upfront investment, the efficiency of the injection molding process reduces per-unit costs for large volumes. For small batches, our flexible production lines minimize waste and setup times, making Custom Spare Parts Molding a cost-effective alternative to modifying standard parts or using more expensive manufacturing methods. The applications of Custom Spare Parts Molding are vast and varied, spanning industries such as automotive, electronics, medical, industrial machinery, and consumer goods. In the automotive industry, for example, Custom Spare Parts Molding is used to produce specialized components like sensor housings, gasket seals, and interior trim parts that are tailored to specific vehicle models. P&M has worked with numerous automotive manufacturers and aftermarket suppliers to deliver custom spare parts that meet the industry’s strict safety and performance standards. Our Custom Spare Parts Molding solutions for the automotive sector are designed to withstand extreme temperatures, vibration, and chemical exposure, ensuring long-lasting reliability. In the electronics industry, Custom Spare Parts Molding plays a crucial role in producing components like connector housings, heat sinks, and circuit board supports. These parts require high precision to ensure proper fit and functionality, and P&M’s Custom Spare Parts Molding service delivers the accuracy needed to meet the demands of this fast-paced industry. We also offer custom coloring and surface finishing options to match the aesthetic requirements of electronic products, adding value to our solutions. The industrial machinery sector relies heavily on Custom Spare Parts Molding for components like gear housings, bearing supports, and hydraulic fittings. These parts are often subjected to heavy loads and harsh operating conditions, so they require high strength and durability. P&M uses premium engineering plastics and composite materials in our Custom Spare Parts Molding process for this sector, ensuring that the parts can withstand the rigors of industrial use. We have also worked with clients to develop custom spare parts that improve the efficiency of their machinery, reducing energy consumption and maintenance costs. The medical industry is another key area where Custom Spare Parts Molding is essential. Medical equipment requires parts that are biocompatible, sterile, and precise, and P&M’s Custom Spare Parts Molding service meets these strict requirements. We use FDA-approved materials and implement cleanroom manufacturing processes to produce parts like surgical instrument handles, diagnostic equipment components, and medical device housings. Our commitment to quality and compliance makes us a trusted partner for medical device manufacturers seeking reliable Custom Spare Parts Molding solutions. As a leading injection mold manufacturer, P&M’s advantages in Custom Spare Parts Molding are clear: our technical expertise, advanced equipment, vertical integration, and client-centric approach set us apart from competitors. We take pride in delivering Custom Spare Parts Molding solutions that not only meet but exceed client expectations, and we are dedicated to building long-term partnerships based on trust and reliability. If you are in need of high-quality custom spare parts that are tailored to your specific needs, we invite you to contact P&M today to discuss your requirements and request a quote. Our team of experts is ready to help you find the perfect Custom Spare Parts Molding solution for your business.

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.