- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Customized in motorcycle spare parts moulding

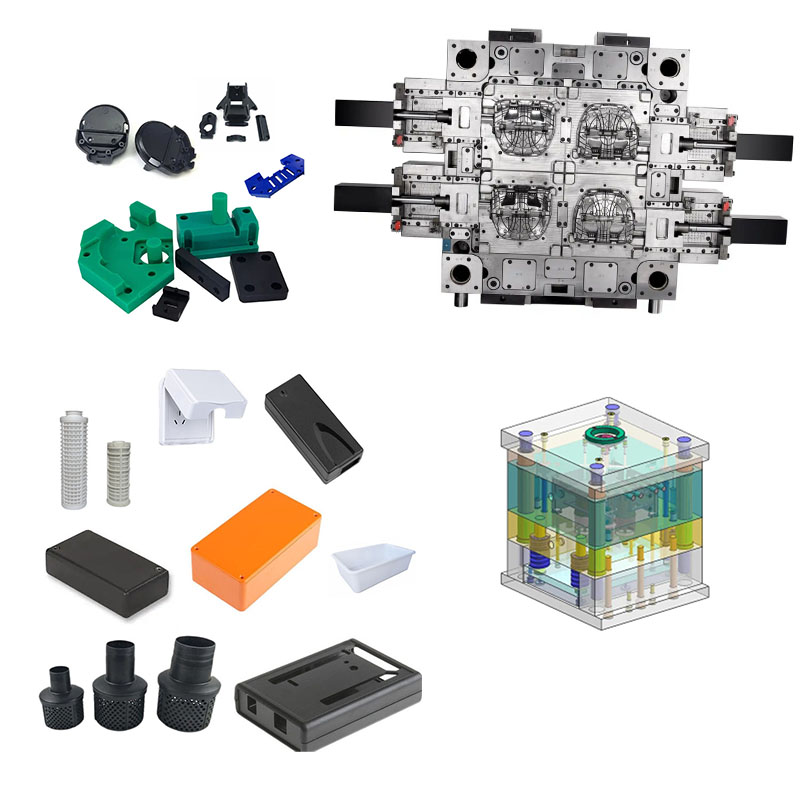

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize customized in motorcycle spare parts moulding. We provide professional customized customized in motorcycle spare parts moulding services, and we are a professional customized in motorcycle spare parts moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing customized in motorcycle spare parts moulding, our factory can provide one-stop service. We have design and production capabilities related to customized in motorcycle spare parts moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized customized in motorcycle spare parts moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For customized in motorcycle spare parts moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

The customization of motorcycle parts is a field with extremely high requirements for safety, performance matching and compliance, which is far stricter than that of general consumer electronic parts. Whether it is custom appearance coverings or core functional components, their success depends on a rigorous engineering process.

Based on the general injection molding process you previously knew, the following are the core customization points for motorcycle parts:

��️ core foundation: security, performance and compliance

This is the prerequisite for all work and is essentially different from the customization of ordinary parts.

Safety and regulations first: It is necessary to clearly define the vehicle model and region where the accessories are to be installed, and study the corresponding safety standards, regulatory certifications (such as DOT, E-mark), and vehicle consistency requirements. For any modified parts that affect the vehicle's structure and safety performance (such as braking and lighting), compliance is the top priority.

Precise performance matching: A motorcycle is a highly coordinated system. Customized parts (especially engine mounts, frame connectors, etc.) will directly affect the handling characteristics of the vehicle. When designing, the impact on the balance of rigidity and toughness of the entire vehicle should be taken into account, and it should be matched with the performance goals of the original vehicle.

Extreme working condition verification: Materials and designs must be able to withstand harsh environments such as vibration, shock, high and low temperature changes, ultraviolet aging, and oil corrosion.

✍️ design and development stage: simulation and accuracy

Precise reverse engineering and data alignment: Customized parts must fit the entire vehicle perfectly. It is often necessary to obtain precise installation interface data through 3D scanning of the original vehicle or original parts, and ensure matching accuracy in CAD design.

Function-oriented DFM (Design for Manufacturability)

Structural design: Lightweighting should be given priority under the premise of meeting the strength requirements. For force-bearing components (such as brackets), their materials, thickness and the size of installation holes will directly affect performance, and topological optimization and strength verification need to be carried out through CAE simulation.

Mold design: Motorcycle parts have complex structures, and molds may require special core-pulling mechanisms. For instance, due to the complex structure of a certain motorcycle's intake manifold, its injection mold is specially designed with two secondary core-pulling mechanisms to ensure smooth demolding. Die-casting molds may adopt structures such as reverse inclined guide pins to enhance quality and efficiency.

In-depth material selection: In addition to the common ABS, PP, PA, and nylon, more high-performance materials will be used based on the functions of the components

Appearance parts: ASA (with better weather resistance than ABS) and PC/ABS (high impact resistance and temperature resistance) are available as options.

Functional components/structural components: Commonly used reinforced PA (nylon + glass fiber) to enhance strength and heat resistance; High-end or competition-grade components will adopt carbon fiber composite materials to achieve ultimate lightweight.

Metal inserts: Metal threaded inserts are often pre-embedded in plastic parts to meet the high-strength requirements of repeated disassembly and assembly. The implantation process is the key.

��️ sample and validation stage: measurement and iteration

This is the most time-consuming and uncompromising part in the customization of motorcycle parts.

Prototype production: Small-batch functional prototypes are made through CNC machining or 3D printing for real vehicle assembly verification, interference checking, and ergonomic evaluation.

Tooling sample (OTS) testing: Samples produced using formal molds must undergo a series of strict tests, including:

Dimensional and durability testing: For key components such as the frame, the precision qualification rate needs to be pursued at an extremely high level (for instance, the process of increasing from 30% to 99% requires extensive testing and process optimization).

Functional and life tests: For instance, customized wheel hubs need to undergo bending fatigue tests and radial impact tests. The engine bracket needs to be simulated for vibration and fatigue on a dedicated bench.

Environmental and chemical tests: weather resistance, temperature resistance, oil resistance, etc.

Real vehicle road test: After passing the bench test, it is necessary to conduct real vehicle tests with sufficient mileage and road conditions to verify the performance of the parts under the actual comprehensive working conditions.

�� mass production and quality control

Process stability: When motorcycle parts are mass-produced, the stability of process parameters is directly related to consistency. It is necessary to optimize the process in advance by means of Moldflow analysis and strictly monitor it during production.

Supply chain and traceability: Select suppliers with automotive industry quality management system certifications such as IATF 16949. For key components, it is required to establish a complete material and production batch traceability system.

In conclusion, the core of customizing motorcycle parts lies in integrating the ultimate requirements for safety and functionality into every detail from design, materials, verification to production

We are a customized in motorcycle spare parts moulding manufacturer, providing high-quality customized in motorcycle spare parts moulding manufacturing. As long as you want to customize/develop customized in motorcycle spare parts moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.