- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

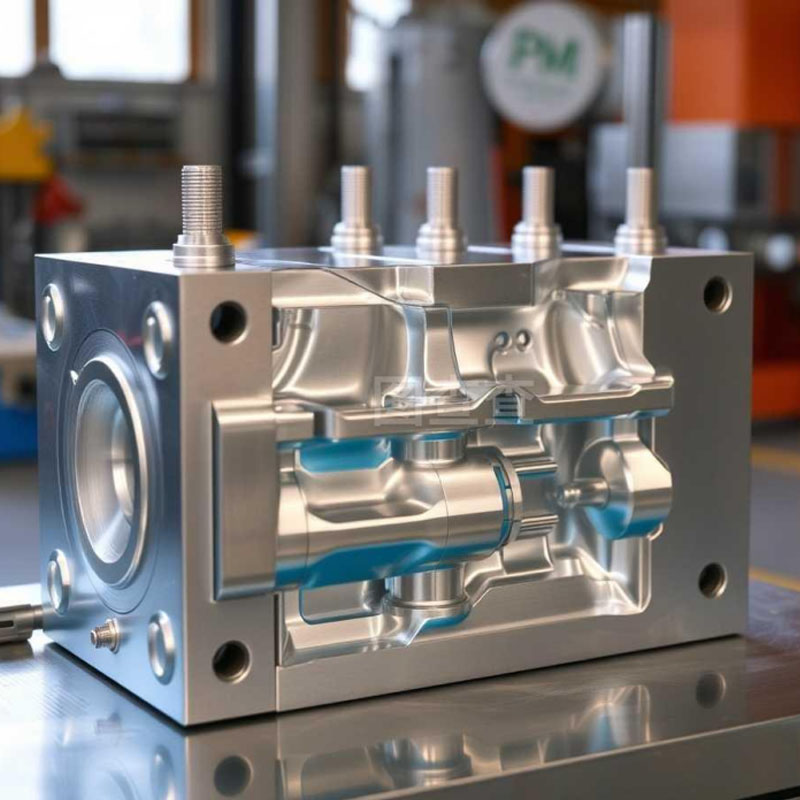

Dental injection moulding die

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize dental injection moulding die. We provide professional customized dental injection moulding die services, and we are a professional dental injection moulding die manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing dental injection moulding die, our factory can provide one-stop service. We have design and production capabilities related to dental injection moulding die, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized dental injection moulding die products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For dental injection moulding die products, we can make corresponding plastic parts, which is mainly done through injection molds.

Dental injection molds are core equipment for precision medical device manufacturing and must meet special requirements such as biocompatibility, micron-level precision, and efficient sterilization adaptability. The following is a systematic analysis based on current technological development and clinical needs:

1. Materials and biosafety control

Mold steel selection

High corrosion resistance + mirror polishing: SUS420J2 (Hitachi, Japan) or German 1.2085 ESR electroslag remelting steel, hardness HRC 52-55, polished to Ra≤0.01μm (to prevent bacterial residue).

Antibacterial coating technology: PVD coating of chromium nitride silver (CrN/Ag), antibacterial rate>99.9% (in line with ISO 22196 standard).

Injection molding raw material specifications

Biocompatible materials:

Thermoplastic materials: PEEK (flexural strength>200MPa, used for implant guides), TPU Shore 85A (invisible braces).

Light-curing resin: 3M Filtek Supreme Ultra (curing shrinkage <1.5%).

Sterilization suitability: withstand 134℃ high pressure steam sterilization for 1000 times (ASTM F1980 accelerated aging verification).

2. Key points of precision mold design

Microstructure molding technology

Occlusal surface bionic texture: Use five-axis laser engraving (accuracy ±2μm) to replicate the micro-grooves of natural enamel (Ra 0.8-1.6μm).

Ultra-thin wall design: The wall thickness of the invisible braces cavity is 0.15-0.3mm, and the mold core uses nano-coating (AlCrN) to reduce demolding resistance.

Hot runner and temperature control system

Micro needle valve hot runner: Φ0.8mm diameter needle valve control to prevent resin degradation (temperature control accuracy ±0.5℃).

Dual-circuit mold temperature controller: front mold 65℃/rear mold 40℃ partition control, balanced shrinkage (warpage deformation <5μm).

3. Key parameters of injection molding process

Injection speed, 50-150mm/s, speed <30mm/s leads to incomplete filling of microstructure

Press holding pressure, 60-80MPa, pressure fluctuation >5% causes stress whitening

Cooling time, 3-8s (adjusted according to wall thickness), uneven cooling leads to occlusal surface accuracy deviation ±10μm

Mold vacuum, ≤-95kPa (to prevent bubbles), residual bubbles lead to a 30% decrease in mechanical strength

Special process application:

Micro-foaming injection molding: supercritical CO₂ assisted molding, 20% weight reduction and improved edge tightness (for removable partial denture brackets).

In-mold assembly technology: simultaneous injection molding of multiple color materials (such as soft and hard glue combined with base), tolerance control ±5μm.

4. Defect prevention and post-processing

Micro-defect zero tolerance strategy

Weld line avoidance: Optimize the gate position through Moldflow simulation to avoid the weld line from the occlusal contact area (clinical failure risk reduced by 70%).

Nano-level cleaning: Plasma cleaning (Ar/O₂ mixed gas) removes mold release agent residues (surface energy>72mN/m).

Intelligent detection system

Optical 3D scanning: Use GOM Atos Core 135 to measure the occlusal surface matching (accuracy 2μm+5μm/m).

AI defect recognition: Deep learning algorithm automatically detects microcracks/flash (accuracy 99.2%, ISO 12836 certification).

V. Industry technology trends in 2025

4D printing molds: Shape memory alloy (NiTi) mold cores realize self-adjusting mold cavities to adapt to personalized crown topology changes.

Bioactive injection molding: Hydroxyapatite spraying system is integrated in the mold, and bone bonding surface is generated synchronously during injection molding (for implant abutments).

Digital twin operation and maintenance: Mold life prediction system (vibration + temperature sensing) warns of wear in advance, reducing maintenance costs by 40%.

Summary

The technical core of dental injection molds lies in the triple balance of **"precision × safety × customization"**. From antibacterial coating to AI detection, each link must comply with the medical device GMP specifications (such as FDA 21 CFR 820). Future technology will break through biofunctional integration and intelligent flexible manufacturing, such as directly generating occlusal surface mold parameters through brain-computer interface data to achieve a seamless closed loop of "diagnosis-treatment-manufacturing".

Dental injection moulding die

We are a dental injection moulding die manufacturer, providing high-quality dental injection moulding die manufacturing. As long as you want to customize/develop dental injection moulding die products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Shaver Moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.