- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

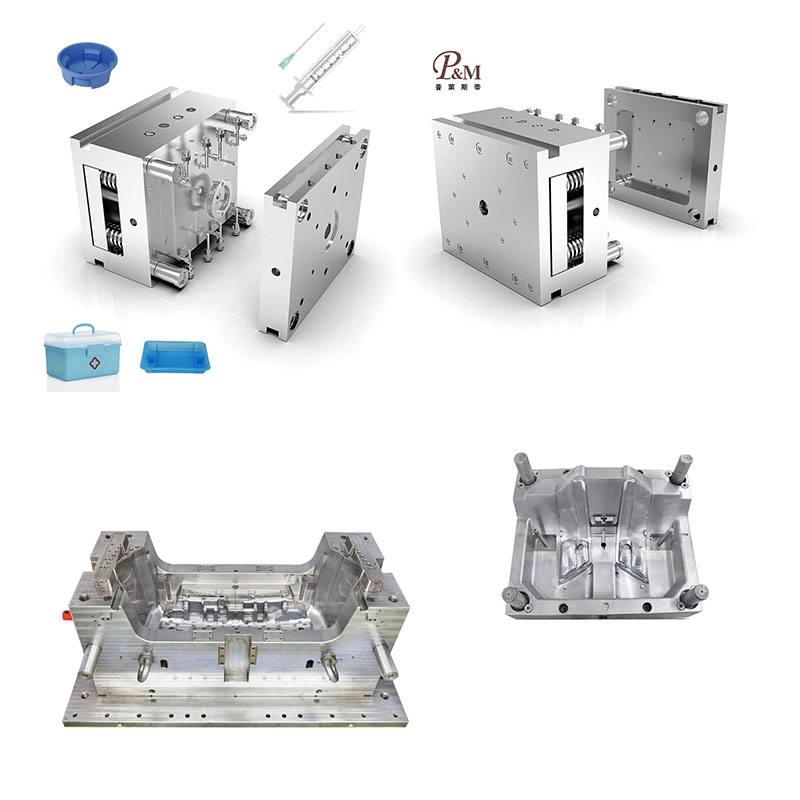

Hot sale custom plastic injection molded parts Moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize hot sale custom plastic injection molded parts. We provide professional customized hot sale custom plastic injection molded parts services, and we are a professional hot sale custom plastic injection molded parts manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing hot sale custom plastic injection molded parts, our factory can provide one-stop service. We have design and production capabilities related to hot sale custom plastic injection molded parts, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized hot sale custom plastic injection molded parts products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For hot sale custom plastic injection molded parts products, we can make corresponding plastic parts, which is mainly done through injection molds.

The core of creating "hot-selling" custom plastic injection molded parts has far exceeded the scope of a single technology. It is a systematic project integrating "rapid response, extreme cost, reliable quality and flexible supply". Best-selling products often face challenges such as tight time to market, large fluctuations in production volume, and high cost sensitivity.

The following are the core points for successfully manufacturing popular custom plastic parts, which is a set of manufacturing logic "born for the market".

Key points of hot-selling custom plastic injection molding parts forming

The First dimension: Strategy and Design - Designed for "Fast" and "Economical"

Parallel Engineering and Ultra-Fast Response

Key point: Mold manufacturers must be deeply involved from the product concept stage and work in parallel with the client's design and marketing teams.

Action: Conduct DFM analysis simultaneously to address all potential production issues during the 3D design stage and shorten the design modification cycle. The goal is that "the day the drawing is frozen is the day the mold starts to work."

Design for Manufacturing and assembly

Key points: Simplify the structure and maximize manufacturability.

Action

Part integration: Integrating multiple functions into a single part to reduce subsequent assembly processes and the number of parts.

Simplify the appearance: Avoid unnecessary complex curved surfaces and overhangs, and prioritize designs that are easy to demold and polish/etch.

Standardization: Use standard parts (such as screws and hinges) as much as possible to facilitate procurement and reduce costs.

The best cost-performance solution for material selection:

Key point: Under the premise of meeting the basic functions, always pursue the most cost-effective materials.

Action: Preferred bulk general-purpose plastics such as PP and ABS. Meet specific requirements by adding appropriate additives (color masterbatches, toughening agents, UV stabilizers), rather than directly choosing expensive high-performance engineering plastics.

The second dimension: Mold Engineering - The Balance between Efficiency and Investment

Molds are the largest single investment, and their design directly determines production efficiency and unit cost.

High cavity number molds and hot runners

Key point: This is the physical law for reducing the cost per unit.

Action: Adopt a single-cavity multi-chamber system (such as 64-hole, 128-hole) and a fully heated runner system (needle valve type). This can greatly increase the single output, shorten the cycle, and achieve a utilization rate of nearly 100% from scrap to waste and raw materials.

A stable rather than overly precise mold

Key point: For best-selling products with a potentially short life cycle, mold design should strike a balance between "lifespan" and "cost".

Action: Use standard formwork bases and cost-effective steel materials (such as high-quality domestic P20 and 718). The design of the cooling and exhaust systems must be efficient and reliable, but there is no need to overdesign in pursuit of ultimate theoretical perfection, which could lead to a sharp increase in mold costs.

Rapid mold testing and verification

Key point: Time is the lifeline of best-selling products.

Action: Utilize mold flow analysis to avoid major issues in advance. Arrange a tight mold trial plan and use the DOE method to quickly lock in the core process window during the mold trial, rather than pursuing the ultimate optimization of all parameters.

The third dimension: Production and Operation - Stability, Flexibility and visualization

Process standardization and stability

Key point: Ensure that every batch and every mold of products is consistent.

Action: Establish standard operating procedures and process parameter tables. Even if multiple injection molding machines are used to produce the same product, it is necessary to ensure the portability and stability of the process.

Supply chain and capacity elasticity

Key point: Orders for best-selling products may fluctuate sharply, and the supply chain must be flexible.

Action: Suppliers should have the ability to quickly adjust production lines and possess reliable raw material reserves and a secondary supplier network. It can provide full-cycle production support from "climbing uphill - peak - fall back".

Transparent communication and data sharing

Key point: Enable customers to have real-time access to the production status.

Action: Regularly provide production progress reports, quality data (such as SPC charts), and inventory status. Even open up visualization Windows for some production data to build mutual trust.

The fourth dimension: Quality and Delivery - The bottom Line for Building Trust

Key quality control

Key points: Focus on the quality characteristics that customers care about the most and have the most fatal impact.

Action: Clarify CTQ (Critical Quality Characteristics), such as flawless appearance, key assembly dimensions, and safety performance. Implement focused monitoring and full inspection of these characteristics rather than uneconomical over-inspection of all dimensions.

Efficient Packaging and Logistics

Key point: Prevent the product from being damaged at the final stage of delivery.

Action: Design packaging solutions that are quick to operate, highly protective, and have a high space utilization rate (such as blister trays + cartons). Optimize container loading to reduce logistics costs.

We are a hot sale custom plastic injection molded parts manufacturer, providing high-quality hot sale custom plastic injection molded parts manufacturing. As long as you want to customize/develop hot sale custom plastic injection molded parts products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.