- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Injection Molding Plastic Parts

Injection Molding Plastic Parts have become an indispensable cornerstone in modern manufacturing, driving the production of countless products that permeate our daily lives and industrial operations. As a professional injection mold manufacturer, P&M has long been deeply engaged in the field of Injection Molding Plastic Parts, accumulating rich experience and advanced technologies to provide high-quality solutions for global customers. The reason why Injection Molding Plastic Parts can occupy a core position in the manufacturing industry lies in their high efficiency, precision and stability, and these advantages can only be fully exerted with the support of high-quality injection molds. P&M has always taken the production of high-performance molds as its core, ensuring that every batch of Injection Molding Plastic Parts produced by customers using our molds meets strict quality standards. Whether it is small precision components or large structural parts, Injection Molding Plastic Parts produced with P&M molds can show excellent performance, winning wide recognition from customers in various industries.

Send Inquiry

For Injection Molding Plastic Parts, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 12 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

P&M Injection Molding Plastic Parts Introduction

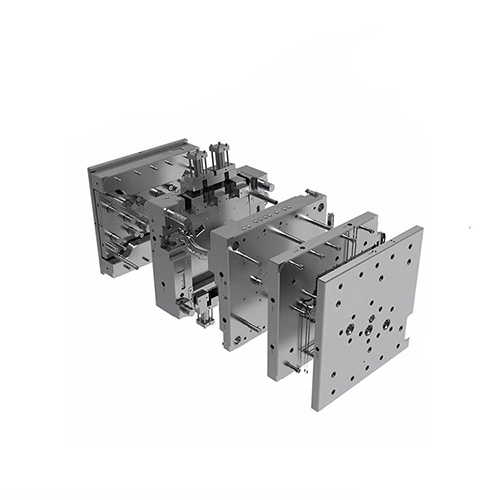

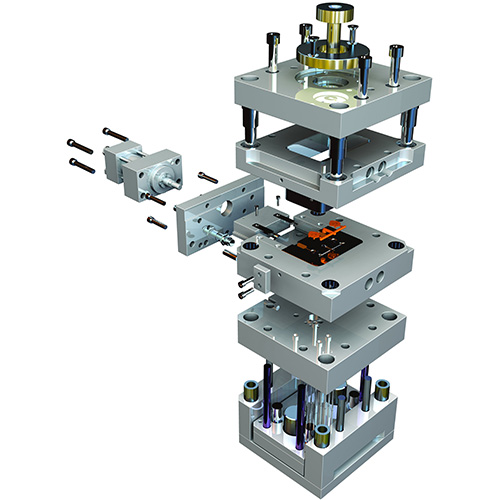

Injection Molding Plastic Parts refer to plastic products manufactured through the injection molding process, a technology that injects molten plastic material into a closed mold cavity under high pressure, and then cools and solidifies to form the required shape. This process involves multiple key links, including mold design, material selection, injection parameter setting, and post-processing, each of which has a direct impact on the quality and performance of Injection Molding Plastic Parts. As a professional injection mold manufacturer, P&M has a deep understanding of every link of the injection molding process, and integrates this understanding into mold design and manufacturing, providing a strong guarantee for the production of high-quality Injection Molding Plastic Parts. The injection molding process for producing Injection Molding Plastic Parts has the characteristics of high automation, high production efficiency and strong repeatability, which can realize mass production of plastic parts with consistent specifications. This is particularly important for industries with large demand for parts, such as automobiles, home appliances and electronics. P&M's molds are designed with fully automated production needs in mind, optimizing the mold structure to reduce molding cycles and improve production efficiency. At the same time, we will conduct in-depth communication with customers before mold manufacturing to clarify the performance requirements of Injection Molding Plastic Parts, such as strength, heat resistance, and corrosion resistance, and then select appropriate mold materials and design schemes to ensure that the molds can adapt to the production of specific Injection Molding Plastic Parts. In addition, the diversity of plastic materials also provides a broad space for the application of Injection Molding Plastic Parts. Common materials include polyethylene, polypropylene, ABS, polycarbonate, etc. Different materials have different properties, and P&M will provide professional material selection suggestions based on the use environment and functional requirements of Injection Molding Plastic Parts, helping customers achieve the best balance between product performance and cost. The production of Injection Molding Plastic Parts is a systematic project, and the quality of the mold is the core factor determining the final product quality. P&M has always adhered to strict quality control standards in mold manufacturing, from raw material procurement to mold processing, assembly and testing, every step is carefully controlled to ensure that each mold can stably produce high-quality Injection Molding Plastic Parts.

The development of Injection Molding Plastic Parts is also closely linked to technological progress. With the continuous advancement of technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM), the design and manufacturing accuracy of injection molds has been greatly improved, which has promoted the upgrading of Injection Molding Plastic Parts towards higher precision and more complex structures. P&M has always kept pace with the times, introducing advanced CAD/CAM systems and precision processing equipment, such as CNC machining centers, EDM machines and wire cutting machines, to realize the precise processing of mold parts. This not only improves the dimensional accuracy of Injection Molding Plastic Parts, but also enables the production of complex-shaped parts that were difficult to process in the past, expanding the application scope of Injection Molding Plastic Parts. For example, in the automotive industry, many complex structural parts and interior parts are produced as Injection Molding Plastic Parts, which require high precision and surface quality. P&M's precision molds can fully meet these requirements, ensuring that the assembled parts have good matching and stability. In the process of introducing new technologies, P&M also pays attention to the training of technical teams, establishing a team of engineers with rich experience and professional skills. They can quickly respond to customer needs, provide personalized mold design solutions, and solve various technical problems encountered in the production of Injection Molding Plastic Parts for customers. Whether it is the optimization of mold structure or the adjustment of injection parameters, P&M's technical team can provide professional guidance, helping customers improve production efficiency and product quality.

Another important aspect of Injection Molding Plastic Parts introduction is the environmental protection and sustainability of the production process. With the increasing awareness of global environmental protection, the manufacturing industry has put forward higher requirements for energy conservation and emission reduction. P&M actively responds to this call, integrating environmental protection concepts into mold design and manufacturing. For example, by optimizing the mold cooling system, we can shorten the cooling time of Injection Molding Plastic Parts, reduce energy consumption; at the same time, we promote the use of environmentally friendly plastic materials and recycling technologies, reducing the environmental impact of waste plastic. In addition, P&M's molds have a long service life, which can reduce the frequency of mold replacement, thereby reducing the waste of resources. The environmental protection advantages of Injection Molding Plastic Parts produced with P&M molds have won the favor of many environmentally conscious customers, helping them enhance their corporate social responsibility image.

P&M Injection Molding Plastic Parts(Specification)

|

Mould Name |

Injection Molding Plastic Parts |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Injection Molding Plastic Parts Feature And Application

Injection Molding Plastic Parts have a series of outstanding features that make them widely used in various industries. As a professional injection mold manufacturer, P&M's mold design and manufacturing technology fully taps and exerts these features, making Injection Molding Plastic Parts more competitive in the market. One of the core features of Injection Molding Plastic Parts is high precision. The mold manufactured by P&M adopts high-precision processing equipment and strict quality control, which can ensure that the dimensional tolerance of Injection Molding Plastic Parts is controlled within a very small range. This is crucial for products that require precise assembly, such as electronic components and automotive parts. For example, the plastic shells of mobile phones and computers have high requirements on size and flatness. Injection Molding Plastic Parts produced with P&M molds can perfectly meet these requirements, ensuring the appearance and assembly quality of products. Another important feature is good consistency. The injection molding process has strong repeatability, and under the same process parameters, the Injection Molding Plastic Parts produced by the same mold have almost the same specifications and performance. P&M optimizes the mold runner system and gate design to ensure uniform filling of molten plastic in the mold cavity, avoiding defects such as uneven wall thickness and bubbles, and further improving the consistency of Injection Molding Plastic Parts. This feature is particularly important for mass production industries, as it can reduce product rejection rates and improve production efficiency.

In addition to high precision and good consistency, Injection Molding Plastic Parts also have the characteristics of diverse shapes and strong material adaptability. With the support of P&M's professional mold design team, customers can realize the production of Injection Molding Plastic Parts with complex shapes and special structures, meeting the personalized needs of different products. For example, in the medical device industry, many plastic parts have complex internal channels and precise surface structures, which can be accurately manufactured through P&M's precision molds. In terms of material adaptability, Injection Molding Plastic Parts can use a variety of plastic materials, including thermoplastics, thermosetting plastics, and reinforced plastics. P&M will select appropriate mold materials and processing technologies according to the properties of different materials to ensure that the molds can adapt to the processing requirements of various materials. For example, when producing high-temperature resistant Injection Molding Plastic Parts, P&M will use high-temperature resistant mold steel and optimize the mold cooling system to prevent mold deformation and ensure product quality. The diverse shapes and strong material adaptability of Injection Molding Plastic Parts greatly expand their application scope, making them play an important role in various fields.

The application of Injection Molding Plastic Parts covers almost all fields of national economy, and P&M's molds have provided strong support for customers in various industries. In the automotive industry, Injection Molding Plastic Parts are widely used in automotive interiors (such as instrument panels, door panels, seat cushions), exteriors (such as bumpers, fenders, headlights) and engine parts (such as intake manifolds, valve covers). The automotive industry has strict requirements on the strength, heat resistance and impact resistance of Injection Molding Plastic Parts. P&M's molds are designed with these requirements in mind, using high-strength mold materials and optimizing the mold structure to ensure that the produced plastic parts can withstand harsh working environments. For example, the automotive bumper produced with P&M's molds has excellent impact resistance, which can effectively protect the safety of the vehicle and passengers. In the home appliance industry, Injection Molding Plastic Parts are essential components of various home appliances, such as the shells of refrigerators, air conditioners, washing machines, and the internal components of microwave ovens and rice cookers. The home appliance industry pays attention to the appearance quality and cost performance of Injection Molding Plastic Parts. P&M optimizes the mold surface treatment process to make the produced plastic parts have a smooth and beautiful surface; at the same time, by improving the mold production efficiency and extending the mold service life, it helps customers reduce production costs.

In the electronics industry, Injection Molding Plastic Parts are widely used in the production of electronic product shells, connectors, insulators and other components. The electronics industry has extremely high requirements on the precision and insulation performance of Injection Molding Plastic Parts. P&M uses precision processing equipment to ensure the dimensional accuracy of the mold, and selects appropriate mold materials and processing technologies to ensure that the produced plastic parts have good insulation performance. For example, the connector shell produced with P&M's molds has precise pin holes and good electrical insulation, ensuring the stable operation of electronic equipment. In the medical device industry, Injection Molding Plastic Parts are used in the production of medical catheters, syringes, surgical instruments and other products. The medical device industry has strict requirements on the biocompatibility and sterility of Injection Molding Plastic Parts. P&M uses medical-grade mold materials and adopts a clean production environment to ensure that the molds do not contaminate the plastic parts during the production process. At the same time, we will conduct strict testing on the molds to ensure that they meet the medical industry standards. In addition, Injection Molding Plastic Parts are also widely used in construction, toys, packaging and other industries. In the construction industry, they are used in pipes, fittings, decorative parts, etc.; in the toy industry, they are used in various toy bodies and accessories; in the packaging industry, they are used in plastic bottles, boxes, lids, etc.

As a professional injection mold manufacturer, P&M has unique advantages in providing support for the production of Injection Molding Plastic Parts. First of all, we have a professional R&D and design team. The team members have more than ten years of experience in mold design and are familiar with the characteristics and production processes of various Injection Molding Plastic Parts. They can provide customers with one-stop solutions from product design optimization to mold design and manufacturing. Secondly, we have advanced production equipment and strict quality control system. We have introduced a full set of precision processing equipment from abroad and established a complete quality control process from raw material inspection to mold testing, ensuring that each mold meets high-quality standards. Thirdly, we have a perfect after-sales service system. After the mold is delivered, we will send professional technicians to provide on-site guidance, help customers debug the mold and solve various problems encountered in the production process of Injection Molding Plastic Parts. In addition, we have strong cost control capabilities, which can provide customers with high-quality molds at competitive prices, helping customers reduce production costs and improve market competitiveness. Injection Molding Plastic Parts are an important part of modern manufacturing, and high-quality injection molds are the key to producing high-performance Injection Molding Plastic Parts. If you are looking for a reliable injection mold manufacturer to support your Injection Molding Plastic Parts production, please feel free to contact P&M. We will provide you with professional solutions and preferential quotes to help you achieve greater success in the market.

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.