- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Injection moulded magnets

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize injection moulded magnets. We provide professional customized injection moulded magnets services, and we are a professional injection moulded magnets manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing injection moulded magnets, our factory can provide one-stop service. We have design and production capabilities related to injection moulded magnets, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized injection moulded magnets products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For injection moulded magnets products, we can make corresponding plastic parts, which is mainly done through injection molds.

Key points and process analysis of injection molded magnets

(Based on magnetic materials and intelligent molding technology in 2025)

1. Material selection and pretreatment

Magnetic powder system optimization

NdFeB base material:

Powder particle size D50 = 5-8μm (distribution width ≤ 1.5), oxygen content < 800ppm

Surface silane coupling treatment (KH550: magnetic powder = 1.5:100), improve the bonding strength with PA12 to > 25MPa

Ferrite (SrFe12O19) solution:

Anisotropic powder orientation > 92% (pulse magnetic field assistance required)

Add 1-2% nano Al₂O₃ to improve temperature resistance (working temperature → 180℃)

Binder system

Nylon 12, 85-92wt%, excellent fluidity (MFI = 15g/10min)

PPS, 88-93wt%, temperature resistance 240℃ (preferred for automotive grade)

Bio-based PLA, 80-85wt%, carbon footprint↓50% (toughening modification required)

II. Magnetic field assisted mold design

1. Magnetic circuit topology (2025 breakthrough technology)

graph LR

A[pulse magnetic field generator] --> B[multipolar orientation module]

B --> C[magnetic field strength 0.8-1.5T]

C --> D[gradient magnetic field design]

D --> E[magnetic powder orientation > 95%]

Innovative design:

Programmable electromagnetic pole array (128 independent control units)

Real-time magnetic field compensation algorithm (fluctuation <±2%)

2. Wear-resistant protection system

Mold cavity adopts WC-Co hard alloy coating (thickness 50μm, HV≥1800)

Diverter plate is coated with diamond-like carbon (DLC) film (friction coefficient <0.1)

III. Intelligent injection molding process

Key process and parameter control

Magnetic powder mixing, Twin-screw temperature control segment (feeding segment → mixing segment → homogenization segment), temperature gradient: 160℃→200℃→180℃

Injection filling, AI prediction of magnetic powder motion trajectory (pressure-speed self-adjustment), filling time deviation <0.1s

Magnetic field orientation, dynamic frequency modulation (20-100Hz pulse), orientation angle error <0.5°

Cooling and shaping, ultrasonic assisted crystallization (frequency 28kHz), residual stress ↓40%

Post-magnetization, Multi-pole synchronous magnetization (peak magnetic field 3.0T), surface magnetic flux density ≥450mT

IV. Defect prevention and control and detection standards

Solutions for high-incidence defects

Magnetic powder agglomeration:

Supercritical CO₂ dispersion is introduced during the mixing process (pressure 15MPa, temperature 40℃)

Online particle size monitoring (laser diffraction method) feedback adjustment of screw speed

Orientation deviation:

Implanted magnetic domain sensor (TMR element) to correct magnetic field direction in real time

Deep learning to compensate for mold deformation (deformation prediction accuracy ±3μm)

Quality inspection system

Magnetic properties: BH curve test (B_r≥0.6T, H_cj≥600kA/m)

Durability: 85℃/85%RH 1000h aging magnetic loss <8% (IEC 60404-8 standard)

Structural integrity: Industrial CT scanning (resolution 5μm) detects internal porosity <0.3%

V. 2025 Technology Frontiers and Applications

4D magnet printing:

Magnetic field programming + shape memory polymer to achieve variable magnetic pole distribution (medical robot application)

Quantum magnetic sensing:

Diamond NV color center sensor embedded in mold, nanoscale magnetic domain monitoring

Green recycling technology:

Hydrogen crushing method (HPMS) to recycle magnetic powder, performance recovery rate >90% (UL 2809 certified)

Cost-performance balance formula

Comprehensive performance index = (magnetic energy product × life) / (cost × carbon footprint)

injection moulded magnets

We are a injection moulded magnets manufacturer, providing high-quality injection moulded magnets manufacturing. As long as you want to customize/develop injection moulded magnets products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Shaver Moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

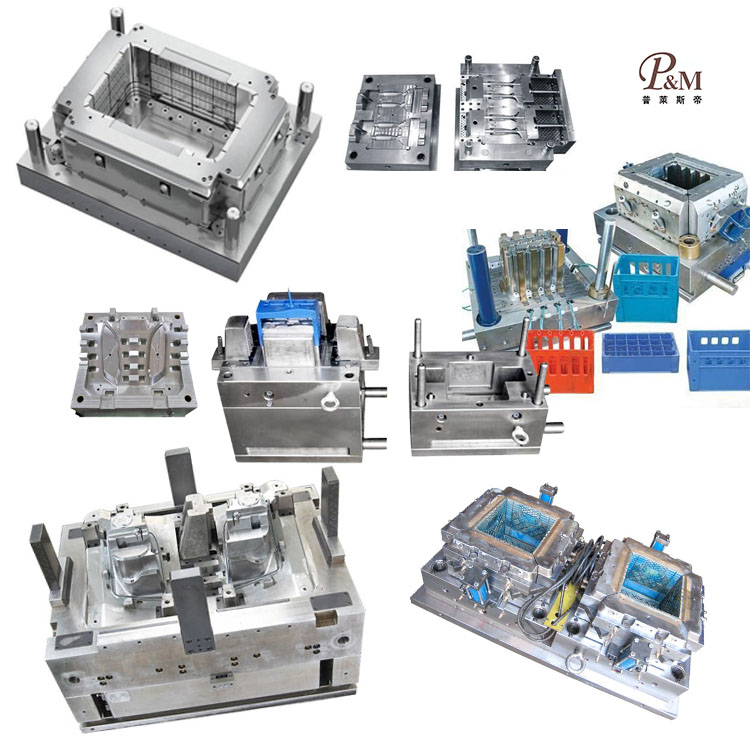

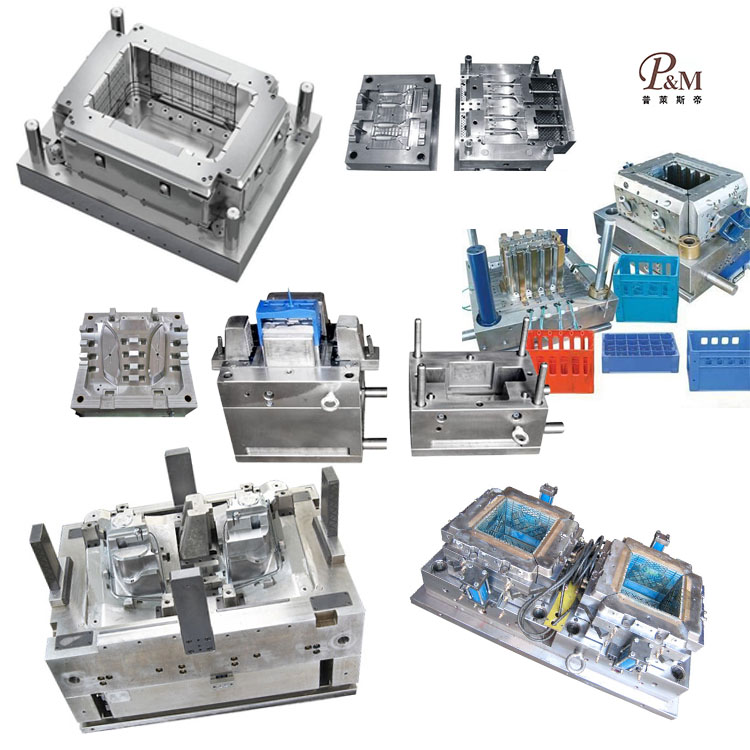

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.