- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

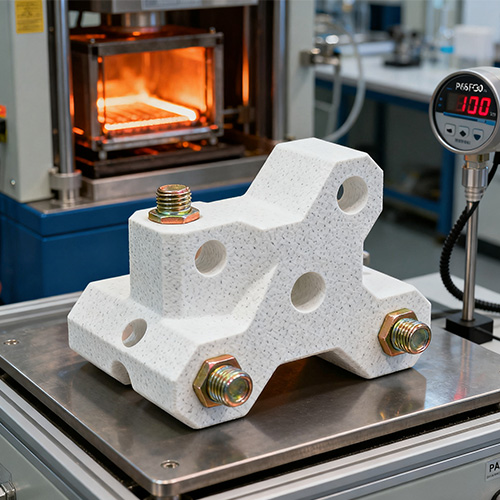

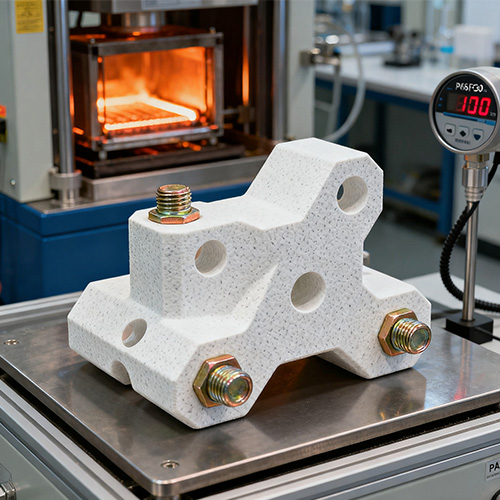

Injection Moulding PaGf30

For Injection Moulding PaGf30, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

Send Inquiry

30% Glass Fiber Reinforced Polyamide (abbreviated as PaGf30) refers to a composite injection molding material formed by uniformly adding 30% mass ratio of glass fiber (GF) to a polyamide (PA, commonly known as nylon, with common models PA6 and PA66) base material. Through the synergistic effect of glass fiber and PA base material, its mechanical properties (such as strength, rigidity, wear resistance) are 2-3 times higher than that of pure PA, while retaining the advantages of PA materials such as good chemical corrosion resistance and temperature resistance. It is one of the core injection materials used in the industrial field to replace metals (such as aluminum alloy, cast iron) for manufacturing structural parts. Injection Moulding PaGf30 specifically refers to the technology of producing high-precision, high-strength structural parts through the injection molding process using this composite material, which is widely used in automotive, electronics, machinery, home appliance and other fields.

P&M Injection Moulding PaGf30 Introduction

A、Core Material Properties of PaGf30

1. High Strength and Rigidity

The mechanical properties of PaGf30 are significantly improved due to the reinforcing effect of glass fiber: taking Pa66Gf30 as an example, its tensile strength can reach 150-180MPa (2.5 times that of pure PA66), flexural strength reaches 200-230MPa (pure PA66 is about 80MPa), and flexural modulus reaches 8000-10000MPa (pure PA66 is only 2500MPa). It can withstand long-term static loads or dynamic impacts without deformation; even in high-temperature environments (such as 100℃), its strength retention rate is still above 80%, far better than pure PA (strength attenuation of 40%-50% at high temperatures), making it suitable for manufacturing load-bearing structural parts such as automotive engine peripherals and mechanical transmissions.

2. Excellent Wear Resistance and Fatigue Resistance

The addition of glass fiber reduces the friction coefficient of PaGf30 to 0.2-0.3 (pure PA is about 0.4-0.5), and the wear rate is ≤0.001mm³/(N・m), which is 1/3-1/2 of pure PA. It can be used for sliding or rotating parts (such as gears, bearings, sliders) for a long time, and can reduce wear without additional lubrication; at the same time, its bending fatigue life is more than 10⁷ cycles (pure PA is about 10⁶ cycles). In high-frequency stress scenarios (such as automotive door hinges, mechanical connecting rods), the service life is 3-5 times longer than that of pure PA, reducing the frequency of part replacement.

3. Good Temperature Resistance and Chemical Resistance

PaGf30 retains the temperature resistance advantage of the PA base material, with a long-term service temperature range of -40℃ to 120℃ (Pa6Gf30) and -40℃ to 150℃ (Pa66Gf30), and can withstand short-term high temperatures of 180℃ (Pa66Gf30). It can still maintain structural stability in high-temperature scenarios such as automotive engine compartments (temperature often reaches 120-140℃) and around home appliance ovens; in terms of chemical resistance, it can withstand common industrial chemicals (such as engine oil, gear oil, dilute acid, dilute alkali) without obvious corrosion or performance attenuation after contact, and is only easily damaged in strong oxidizing solutions (such as concentrated nitric acid), making it suitable for scenarios involving oil pollution such as chemical machinery and automotive transmission systems.

4. Dimensional Stability and Molding Characteristics

The molding shrinkage rate of PaGf30 is significantly lower than that of pure PA: the shrinkage rate of pure PA66 is about 1.5%-2.5%, while that of Pa66Gf30 is only 0.4%-0.8%, and the shrinkage is uniform (longitudinal and transverse shrinkage difference ≤0.2%), which can reduce the risk of warping and deformation of injection molded parts, and ensure that the dimensional tolerance of high-precision structural parts (such as electronic connectors, precision gears) is controlled within ±0.02mm; however, it should be noted that the addition of glass fiber will reduce the material fluidity (melt flow rate MFR is 30%-50% lower than that of pure PA), and injection molding processes (such as increasing temperature and pressure) need to be optimized to ensure complete cavity filling.

B、Key Injection Molding Process Points for PaGf30

1. Raw Material Pretreatment

PaGf30 is hygroscopic (PA base material easily absorbs moisture in the air). If the moisture content is too high (>0.1%), bubbles, silver streaks or degradation are likely to occur during injection molding, so strict drying is required:

Drying Equipment: Use a hot air circulation dryer or a dehumidifying dryer (preferred, which can control the dew point ≤-40℃);

Drying Parameters: Pa6Gf30 drying temperature 80-90℃, time 4-6 hours; Pa66Gf30 drying temperature 100-120℃, time 6-8 hours;

Testing Standard: The moisture content of the material after drying must be ≤0.05% (tested by a moisture meter), and direct exposure to air should be avoided (it must be put into the injection molding machine within 30 minutes after taking it out to prevent secondary moisture absorption).

2. Injection Molding Machine and Mold Requirements

(1) Injection molding machine selection

Locking force: It needs to be 20% -30% higher than pure PA injection molding. The calculation formula is "Locking force (kN)=product projection area (cm ²) × injection pressure (MPa) × safety factor (1.2-1.5)". For example, for Pa66Gf30 injection molded parts with a projection area of 100cm ² and an injection pressure of 120MPa, the locking force needs to be ≥ 100 × 120 × 1.3=1560kN (choose an injection molding machine with 1600kN or above);

Screw: Special fiberglass reinforced material screw (such as nitride steel material, hardness ≥ HRC60, groove depth 10% -15% shallower than ordinary screw) is used to avoid fiberglass wear on the screw; The anti reverse ring should be made of wear-resistant alloy (such as tungsten steel) to prevent melt reflux.

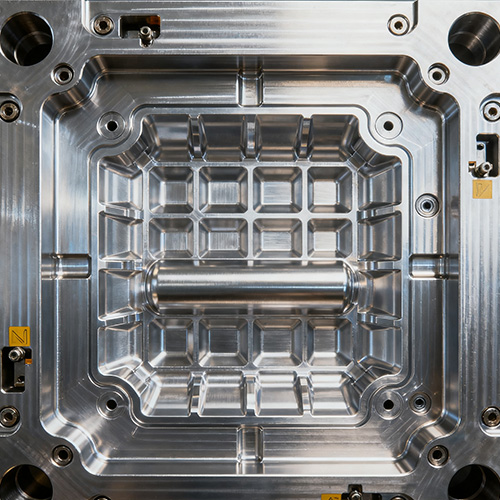

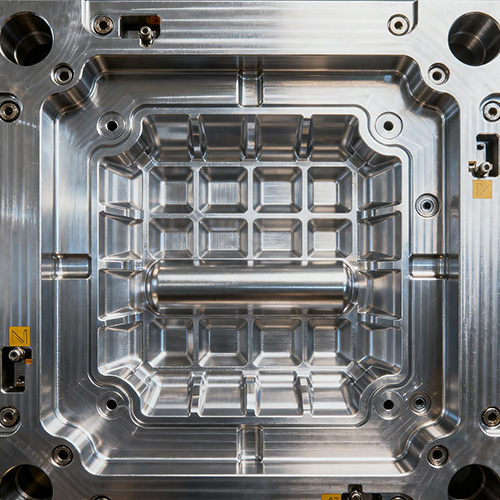

(2) Mold Design

Pouring system: using large-diameter main channels (diameter 8-12mm) and short gates (such as side gates, point gates, length ≤ 5mm) to reduce melt flow resistance; The gate position should avoid the stress area (to avoid local strength reduction caused by glass fiber orientation);

Cooling system: Arrange cooling water channels evenly according to the thickness of the product (spacing 20-30mm, diameter 8-10mm), control the cooling time within 20-40s (adjust according to the thickness, such as cooling 5mm thick products for 30s), ensure uniform cooling of the product, and reduce internal stress;

Exhaust groove: depth 0.03-0.05mm, width 5-10mm, located at the last filling point of the melt (such as the end of the mold cavity or the root of the rib), to exhaust the gas inside the mold cavity and avoid bubbles or material shortage.

P&M Injection Moulding PaGf30(Specification)

|

Mould Name |

Injection Moulding PaGf30 |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Injection Moulding PaGf30 Feature And Application

1. Automotive Industry

Application Parts: Engine peripheral parts (such as intake manifolds, water pump housings), chassis parts (such as suspension brackets, brake pedal brackets), interior structural parts (such as seat frames, instrument panel brackets);

Performance Requirements: Withstand high temperatures of 120-150℃ (engine compartment environment), resist engine oil/gear oil corrosion, static load-bearing ≥500N;

Case Description: Automotive intake manifolds are injection-molded with Pa66Gf30, replacing traditional aluminum alloy materials. The weight is reduced by 40% (from 2.5kg to 1.5kg), the cost is reduced by 30%, and the molding cycle is shortened from 2 hours for aluminum alloy to 20 minutes for injection molding, greatly improving production efficiency.

2. Electronics and Electrical Industry

Application components: electronic connector housing (such as industrial plug socket), motor end cover, transformer frame, internal structural components of new energy vehicle charging piles;

Performance requirements: dimensional accuracy ± 0.02mm (suitable for precision pins), temperature resistance ≥ 120 ℃ (motor heating environment), excellent insulation performance (volume resistivity ≥ 10 ¹⁴Ω· cm);

Advantages: The low shrinkage rate (0.4% -0.8%) of PaGf30 ensures that the coaxiality of the connector housing holes is ≤ 0.01mm, avoiding poor contact of the pins; The temperature resistance meets the long-term heating requirements of the motor, without the need for additional heat dissipation structures.

3. Mechanical and Home Appliance Industry

Mechanical field: gears (such as transmission gears, reducer gears), bearing seats, sliders, mechanical arm structural components; Relying on the high wear resistance of PaGf30 (wear rate ≤ 0.001mm ³/(N · m)), the service life of gears can reach over 10000 hours, far exceeding the 3000 hours of pure PA gears;

Home appliance field: washing machine inner tube bracket, air conditioning compressor bracket, oven door frame reinforcement ribs; PaGf30 needs to withstand the centrifugal force of high-speed rotation of washing machines (≥ 1000rpm) or high temperature of ovens (150 ℃), and its rigidity and temperature resistance can ensure long-term use without deformation.

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.