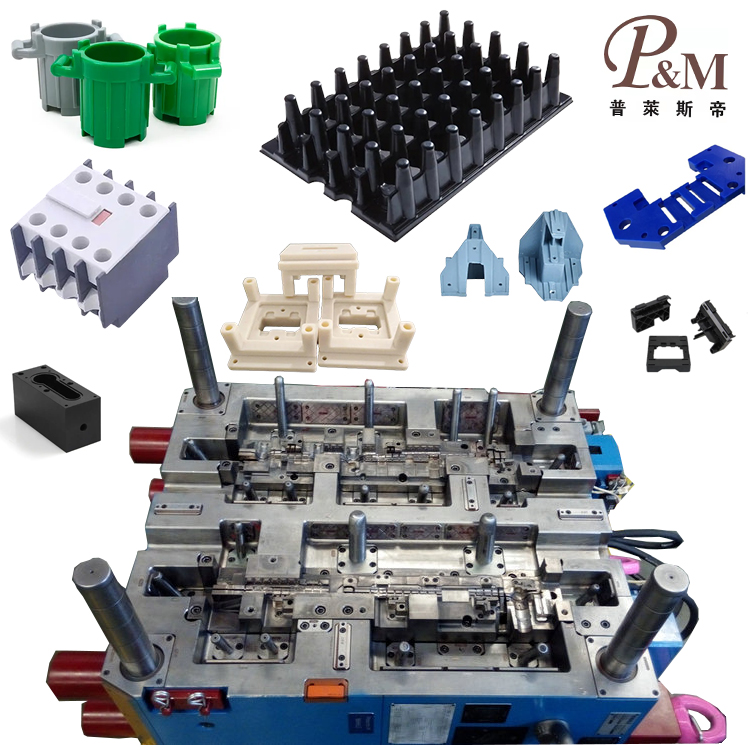

- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Medical injection moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize medical injection moulding. We provide professional customized medical injection moulding services, and we are a professional medical injection moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing medical injection moulding, our factory can provide one-stop service. We have design and production capabilities related to medical injection moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies..

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized medical injection moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For medical injection moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

Medical injection molding needs to meet the requirements of zero defects, biocompatibility, and traceability. The following are systematic technical points and innovative practices

1. Material science breakthroughs (clinical-grade polymers in 2025)

1. High-end material selection matrix

Medical-grade PEEK, orthopedic implants, nano-hydroxyapatite enhancement (bone fusion rate ↑40%)

Gamma-irradiation-resistant COP, prefilled syringes, transparency retention rate after irradiation > 98%

Antibacterial TPE, respiratory mask, silver-loaded zeolite long-term antibacterial (> 99.99% efficiency)

Degradable PLGA, drug sustained-release microsphere carrier, degradation rate AI controllable (error ± 3 days)

2. Ultra-clean environment control (Class 5 clean room standard +)

1. Double revolution of particle control

graph LR

A [environment] --> B (0.3μm particles <100/m³)

C [equipment] --> D (in-mold cleanliness ISO 3 level)

Innovative solutions:

Electrostatic adsorption wind wall (particle sedimentation rate ↓90%)

Mold nitrogen positive pressure protection (oxygen content <50ppm)

2. Dynamic monitoring of microorganisms

Online ATP bioluminescence detection (automatic sampling every 2 hours)

Disinfection upgrade: hydrogen peroxide plasma sterilization (instead of ethanol wiping)

III. Precision mold technology (micron-level precision guarantee)

1. Core design standards

Parting surface flatness, ≤0.005mm, ≤0.02mm

Conformal cooling water channel accuracy, ±0.01mm, ±0.05mm

Demolding slope compensation algorithm, AI real-time deformation correction, fixed compensation value

2. 2025 innovative process

Micro injection molding: embedded production in a Class 100 clean room (minimum part 0.1mg)

Laminar mold technology: production capacity increased by 80% (insulin syringe 24-cavity mold)

IV. Key points of process control (zero-defect production core)

1. Closed-loop control of key parameters

Melt temperature, ±0.5℃, infrared thermal imaging online feedback

Packaging pressure, ±0.2%, cavity pressure sensor array

Cooling uniformity, ΔT≤1.5℃, mold embedded thermocouple

2. Defect prevention technology

Black spot control: supercritical CO₂ barrel cleaning (once per shift)

Internal stress elimination: multi-stage annealing process (temperature control accuracy ±0.3℃)

V. Quality and compliance system (full life cycle traceability)

1. Smart detection system

graph TB

A[First article inspection] --> B(AI visual 100% size comparison)

C[Process sampling] --> D(Micro CT porosity analysis)

E[Finished product test] --> F(Cytotoxicity automatic incubator)

2. Blockchain traceability

Material batch → process parameters → sterilization records are fully chained (compliant with FDA UDI 2.0)

Real-time warning: Deviation data triggers the smart contract to automatically stop production

VI. Green smart manufacturing practice

Energy use, electromagnetic induction heating, energy consumption ↓45%

Waste, supercritical water oxidation recovery, carbon footprint ↓70%

Clean room, ion membrane dehumidification and recycling system, water and electricity consumption ↓60%

VII. Risk control list

Silicone oil migration, ≤0.6μg/cm² (ISO 10993-18), plasma spraying fluorinated release layer

Extractables, USP<665> new standard, accelerated solvent extraction pre-inspection

Data integrity, 21 CFR Part 11 electronic signature, quantum encryption process database

medical injection moulding

We are a medical injection moulding manufacturer, providing high-quality medical injection moulding manufacturing. As long as you want to customize/develop medical injection moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Shaver Moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.