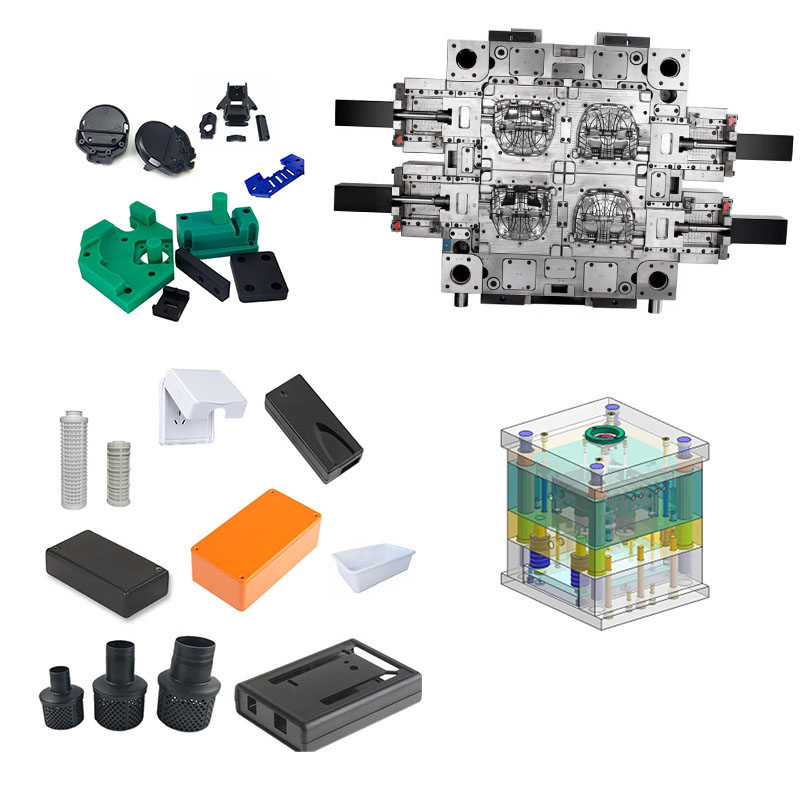

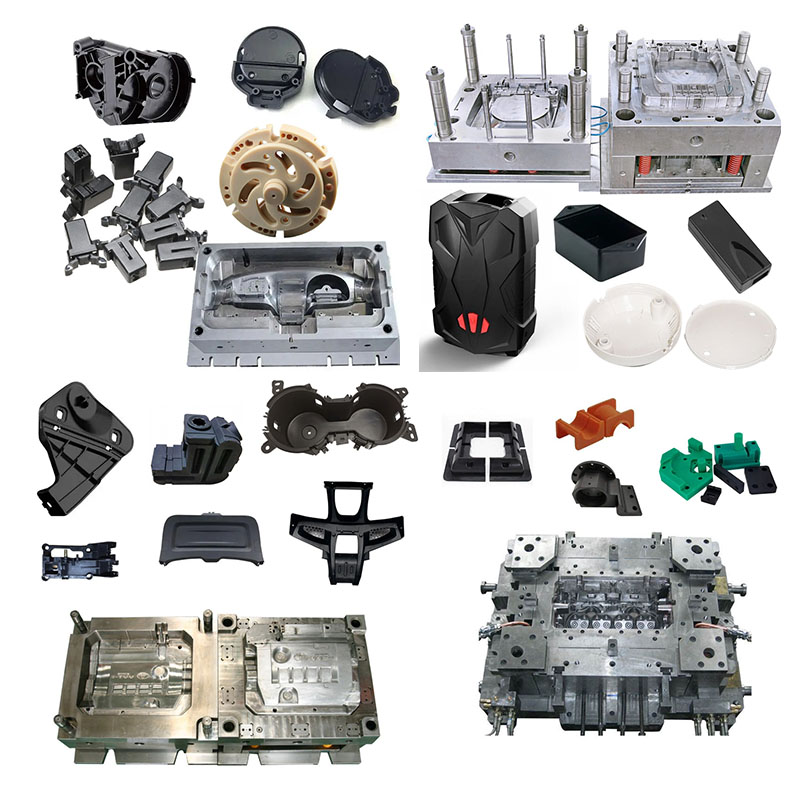

- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Nail parts customization moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize nail parts customization moulding. We provide professional customized nail parts customization moulding services, and we are a professional nail parts customization moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing nail parts customization moulding, our factory can provide one-stop service. We have design and production capabilities related to nail parts customization moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized nail parts customization moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For nail parts customization moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

"Customized nail parts" usually refer to the customized production of wearable nail pieces, decorative accessories (such as diamond jewelry, stickers, metal parts, etc.) or tool accessories in the nail art industry. Whether it is an individual creator, a manicurist or a brand owner, the following core points should be noted when customizing to ensure that the finished product meets expectations and has market competitiveness:

I. Key Points of the Design Stage

Clarify the demand positioning

Target users: Daily consumers, professional manicurists or special occasions (such as weddings, stages)?

Style and theme: Simple, luxurious, cartoon, Chinese style, etc. A clear design direction is required.

Functional requirements: Is it necessary to be waterproof, scratch-resistant, lightweight or reusable?

Design drawings and technical details

Precise dimensions: Provide data on the arc (C arc), width, and length of the nail plate (common sizes such as S/M/L or specific millimeters).

Material selection

The material of the nail plate: ABS plastic (firm), PET (flexible and thin), resin (high transparency), etc.

Decorative materials: crystal diamonds, acrylic diamonds, metal fittings, glass tiles, etc. Indicate whether the gold plating is rust-proof.

Process marking: Details such as hand-painted, spray-painted, embossed, laser-engraved, and inlaid should be indicated in the design drawing.

Ii. Key Points of Production Communication

Sample confirmation

Be sure to make a sample first: confirm that the color, texture and size of the actual product are consistent with the design drawing.

Test compatibility: Try on the armor pieces to see if they fit the armor and whether the accessories are easy to fall off.

Adjustment cycle: Reserve time for modification to avoid direct investment in mass production.

Supplier screening

Qualification review: Examine the factory's past cases, production environment, and compliance certifications (such as environmental protection test reports).

Minimum Order Quantity (MOQ) : Confirm whether to accept small-batch customization to reduce initial inventory pressure.

Communication efficiency: Ensure that the other party can understand the demands of the nail art industry and avoid misunderstandings of terms.

Iii. Quality and Cost Control

Material safety and durability

Environmental protection standards: The nail glue that comes into contact with the skin must comply with safety standards such as RoHS/REACH.

Adhesion test: Decorative components need to pass wear resistance and water resistance tests (such as alcohol wiping).

Packaging protection: Fragile accessories should be packaged independently to prevent damage during transportation.

Cost accounting

Clear quotation sheet: Distinguish mold fees (if any), material fees, processing fees, and packaging fees.

Stepped quotation: Strive for quantity discounts during mass production, but balance inventory risks.

Iv. Practical Suggestions

Intellectual property protection: Original designs should sign confidentiality agreements with suppliers to prevent them from being misappropriated.

Market differentiation: Focus on trends (such as skin-feel nails, dynamic accessories), but avoid over-reliance on popular and outdated elements.

After-sales feedback: After the first batch of customers tried it out, collect the wearing experience and optimize the subsequent batches.

V. Common Pitfalls Avoidance Guide

Preventive measures for potential problems

If the color difference is severe, provide Pantone color codes or physical color cards to avoid screen color differences.

Test the toughness of the material when the nail plate breaks or deforms. Avoid materials that are too thin or prone to aging.

If there is residual or easily peeling glue on the jewelry, the factory is required to provide a bonding test report to confirm the type of glue (it is recommended to use special glue for nail plates).

Dimensional deviation leads to non-conformity. Provide multi-finger module data or request the factory to provide a size chart for verification.

Summary

The core of customizing nail parts lies in "detail control" and "effective communication". From design to production, each link needs to have clear standards and be verified physically. It is recommended that the initial cooperation start with a small batch and gradually establish a reliable supply chain. If there are any special process requirements (such as detachable design, magnetic adsorption, etc.), it is essential to have in-depth communication with technicians about feasibility to ensure that both creativity and practicality are taken into account.

We are a nail parts customization moulding manufacturer, providing high-quality nail parts customization moulding manufacturing. As long as you want to customize/develop nail parts customization moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

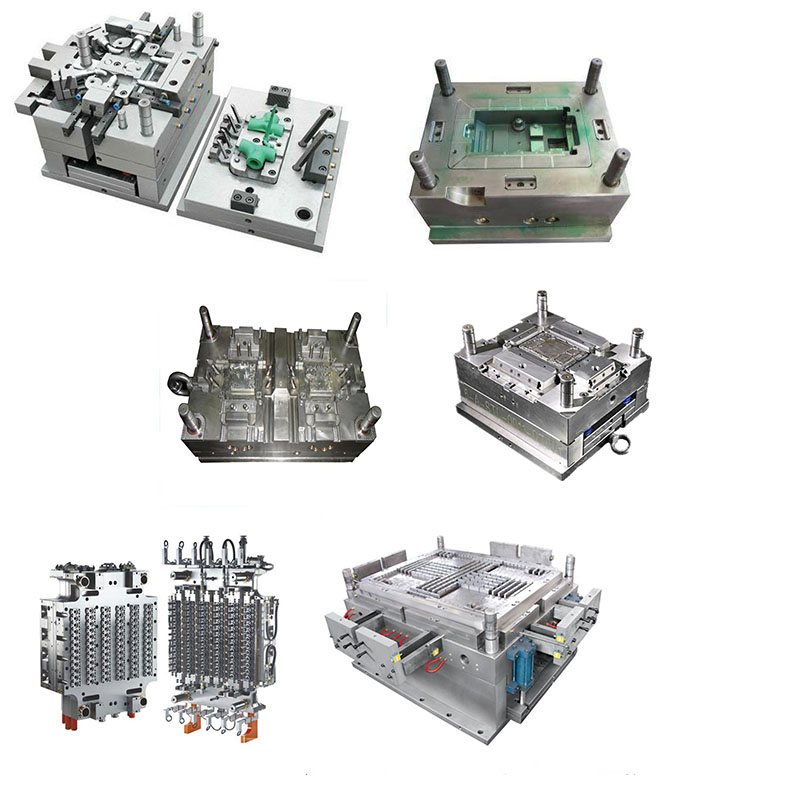

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

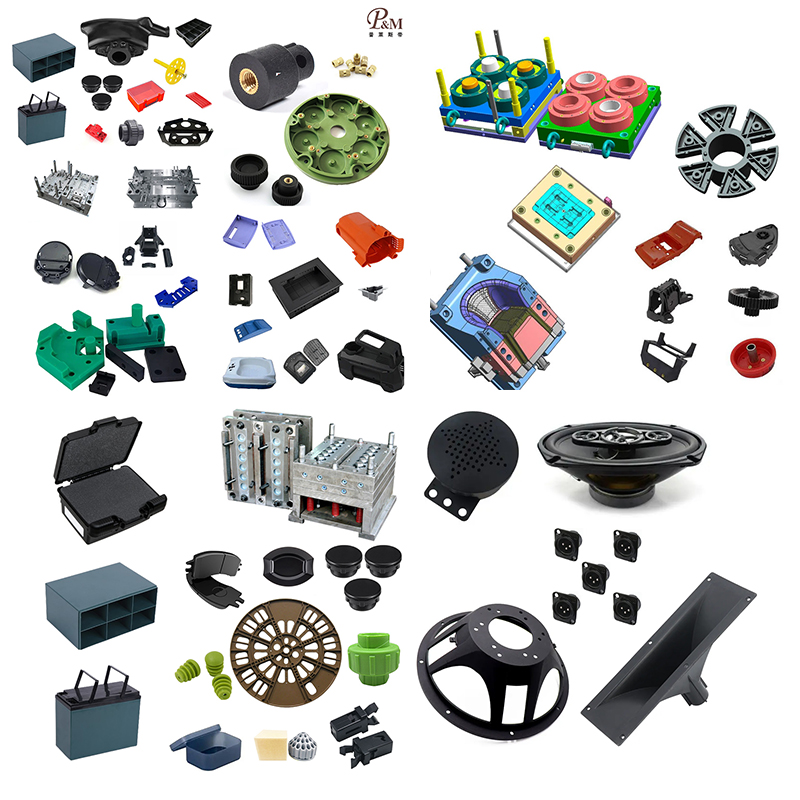

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

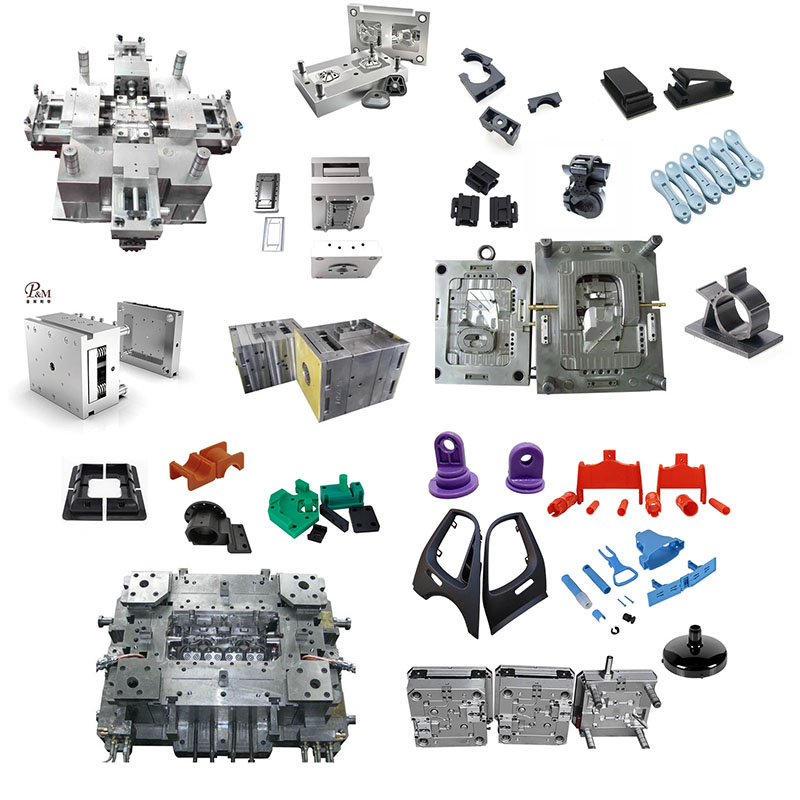

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.