- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Nylon (PA) component molding service

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Custom Injection molded parts. We have ISO 9001 certificates. We provide professional Nylon (PA) component molding service and we are professional custom Nylon (PA) component molding service . We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.

Send Inquiry

We are a specialized manufacturer and technical partner for engineering-grade Nylon (PA) component molding. We produce custom plastic parts and sub-assemblies where strength, wear resistance, and thermal performance are critical. As a dedicated manufacturer, we provide complete in-house expertise—from material science and precision tooling to controlled molding and secondary assembly—delivering components that perform reliably in demanding mechanical and thermal environments.

Our Service: Engineered PA Components & Integrated Assemblies

We manufacture the durable, functional plastic parts that drive mechanisms, bear loads, and withstand friction. Our core service is producing custom nylon components designed for specific mechanical, thermal, and chemical challenges. We add significant value through secondary operations such as machining, press-fitting of bearings or bushings, and assembly, delivering robust, ready-to-install sub-assemblies that simplify your production.

Custom Design for Nylon's Mechanical Demands

Designing for nylon requires engineering that anticipates its unique combination of strength, flexibility, and moisture-sensitive behavior. We optimize every part for long-term performance:

Ribs, Gussets & Wall Thickness: Strategically designed to provide structural reinforcement while managing uniform cooling to minimize warpage caused by semi-crystalline shrinkage.

Bosses & Mounting Points: Reinforced to withstand high pull-out and shear forces from fasteners, often incorporating metal inserts for maximum strength in threaded applications.

Gear & Bearing Design: A core specialty. We engineer tooth profiles, backlash, and hub designs to leverage PA's low friction and high wear resistance for smooth, long-life operation.

Snap-fits & Living Hinges: Designed with calculated strain limits to utilize PA's excellent fatigue resistance and flexibility for secure, repeated assembly/disassembly.

Draft & Shrinkage Allowances: Precisely calculated based on the specific PA grade and reinforcement, ensuring dimensional accuracy and easy part ejection.

Nylon Material Science: Selecting the Right Polyamide for the Application

Nylon is a family of materials, each with distinct properties. We guide you to the optimal type and formulation:

PA6 (Nylon 6): Excellent balance of toughness, wear resistance, and surface finish. The most common grade for gears, rollers, snap-fits, and general mechanical components. It has a lower melt temperature but higher moisture absorption than PA66.

PA66 (Nylon 66): Offers higher strength, stiffness, and heat resistance (HDT ~250°C) compared to PA6. Ideal for high-load structural parts, under-hood automotive components, and electrical connectors.

Glass-Reinforced Nylon (PA6-GF, PA66-GF): The addition of glass fiber dramatically increases stiffness, dimensional stability, and heat deflection temperature while reducing creep. Used for brackets, housings, fan blades, and components requiring metal-like strength.

MoS2 (Molybdenum Disulfide) or Oil-Filled Nylon: Provides enhanced lubricity, lower friction, and improved wear resistance for gears, bearings, and sliding components without external lubrication.

Heat-Stabilized & UV-Stabilized Grades: Formulated to withstand prolonged high-temperature exposure or outdoor weathering, suitable for under-hood automotive parts and outdoor equipment.

Key PA Properties Driving Selection:

High Strength & Toughness: Excellent load-bearing capacity and impact resistance, even at low temperatures.

Outstanding Wear & Abrasion Resistance: Superior performance in moving contact applications, often eliminating the need for lubrication.

Good Chemical Resistance: Withstands oils, fuels, and many solvents, making it ideal for automotive and industrial environments.

High Heat Resistance: Performs reliably in elevated temperature environments where many plastics fail.

The Precision Nylon Molding Process: Mastering a Hygroscopic, Crystalline Material

Molding nylon successfully requires strict discipline and control over moisture and crystallization. Our process is engineered for consistency and optimal properties.

Critical Pre-Process: Drying. Nylon is extremely hygroscopic. We enforce mandatory, precise drying in dehumidifying hopper dryers to reduce moisture to a level (<0.2%) that prevents steam voids, splay, and molecular degradation during processing.

Process Specifics: We utilize higher melt temperatures and fast injection speeds to properly fill molds before the material begins to crystallize. Precise mold temperature control is critical: a hot mold (often 80°C+) promotes crystallization for maximum chemical resistance and dimensional stability, while a cooler mold yields a tougher, more flexible part.

Key Advantages of Our PA Molding Expertise:

Dimensional Stability & Predictable Shrinkage: Through expert mold design and controlled processing, we manage the significant and directional shrinkage of semi-crystalline nylons, especially glass-filled grades, to hit tight tolerances.

Optimized Mechanical Properties: Proper drying and controlled crystallization ensure parts achieve their full potential in tensile strength, stiffness, and impact resistance.

Superior Surface Finish & Appearance: Our process minimizes defects like splay or voids, producing parts with excellent surface quality, critical for gears and visible components.

Post-Molding Conditioning Management: We understand and can advise on the effects of moisture absorption on dimensions and performance, ensuring parts are fit for purpose in their end-use environment.

Why Partner With Us for Nylon Components?

Our differentiation lies in our deep, practical understanding of polyamide behavior—both in the mold and in the field. We provide essential Design for Manufacturability (DFM) analysis focused on nylon's shrinkage and strength characteristics. We own the entire process from moisture-controlled material handling to high-precision tooling and post-molding QA. We are the partner you need for components that must survive stress, heat, and wear.

Choose us for your nylon parts when you need more than just a shape—you need a reliable, high-performance mechanical component. We deliver engineered solutions built to move, bear, and last.

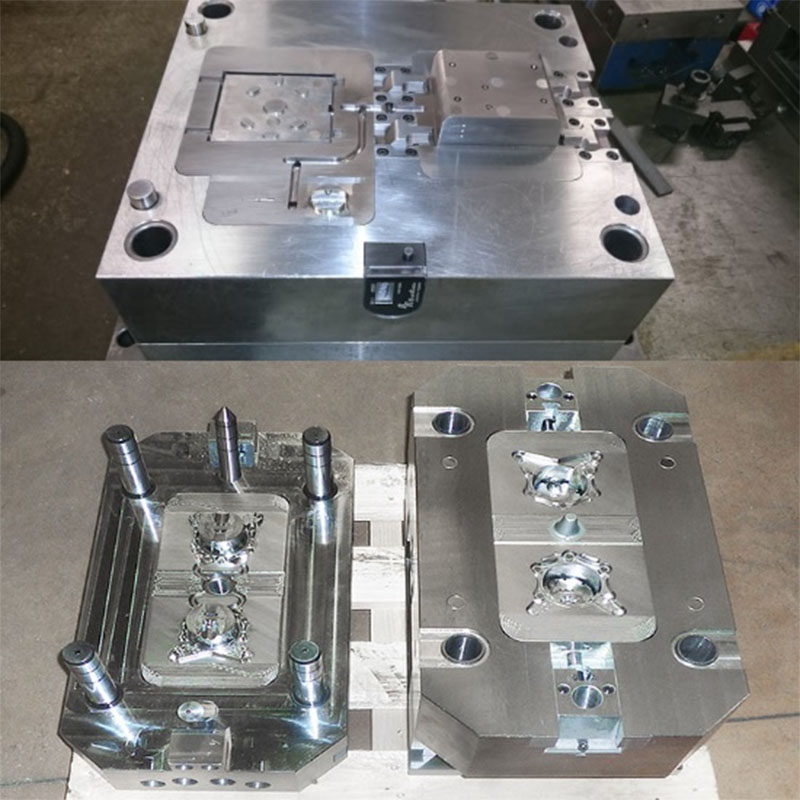

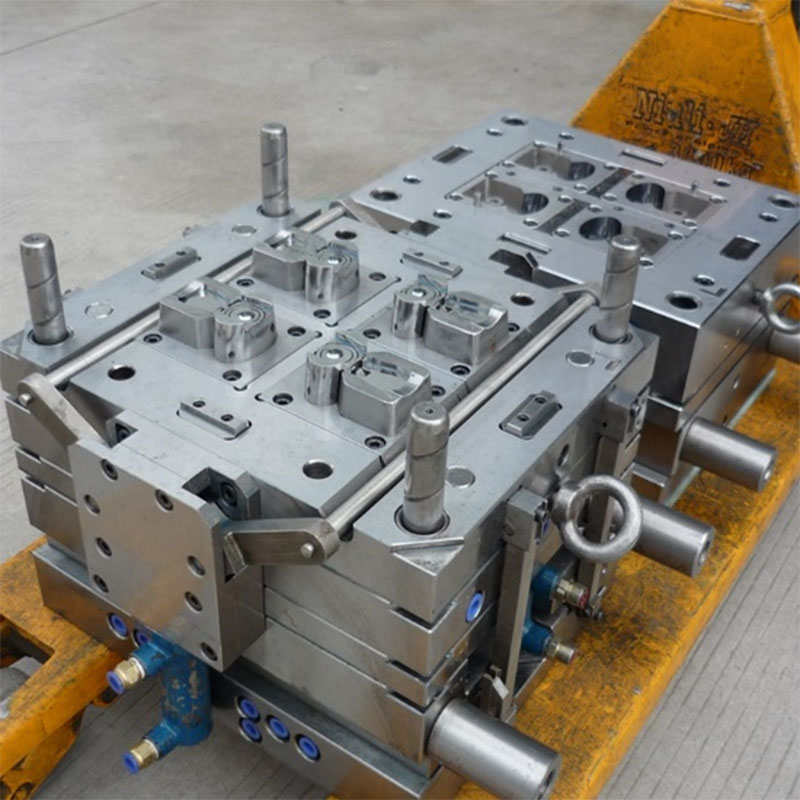

We are plastic mold maker and can provide custom mold service, we can make injection molds, blow molds, rotational molds and die-casting molds.

For custom injection molds, we can provide professional custom injection molding services. Usually Plastic injection mold manufacturing Molding are manufactured using injection molding technology. The mold materials for injection molds can be chosen from P20, 718, S136, H13 and so on. The mold material reflects the mold life and product material requirements.

For parts that require blow molding production, we can also provide professional custom blow molding services.

|

Product Name |

PVC custom molding services

|

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic injection mold manufacturing Injection Mould making

1.We communicate product design according to samples/drawings and your requirements.

2.After the product design is confirmed, we carry out the mold design, we provide all kinds of injection molds, blow molds, silicone molds, die-casting molds services.

3.Material procurement, steel cutting and mold basic tools.

4.Mold assembly

5.Mold inspection, tracking and controlling mold processing.

6. We will inform you the date of mold trial and send you the sample inspection report and injection parameters together with the sample.

7.Your instruction and confirmation of shipment.

8.Prepare the mold before packing.

Plastic injection mold manufacturing molding Specification

1. Professional manufacturer, design, production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Transaction process:

Mold testing:

Once the mold is complete, I do a mold test. It usually takes about 3-5 days to complete. We need to assemble the mold, adjust the pressure data of the machine, and try production. We need to check whether there are problems during the normal production of the mold and make modifications.

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

Factory

Video-1: (Factory Video)

Video-2: (Injection Molding)

Video-3: (Blow molding)

Video-4: (Blow molding)

Video-5: (Roll molding)

Customer satisfaction is our most important goal. We focus on communication and cooperation with our customers, always pay attention to their needs and provide quick response and quality customer service. Our injection production mold factory is committed to establishing long-term relationships and ensuring that our customers receive the best after-sales service during the purchase and use of our products, and we will definitely do our best to solve any problems for our customers.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us?

Mould,Plastic Product, Metal Product,Dental Product,CNC machining.

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6. What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.