- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Plastic Chair Parts Molding

Plastic Chair Parts Molding is the core process that defines the quality, durability, and cost-effectiveness of plastic chair components, serving as the backbone of the furniture manufacturing industry. For manufacturers and buyers alike, mastering or partnering with experts in Plastic Chair Parts Molding is non-negotiable to ensure products meet market demands. As P&M, a professional injection molding manufacturer with years of experience, we have honed our expertise in Plastic Chair Parts Molding to deliver solutions that balance precision and efficiency. Our commitment to excellence in Plastic Chair Parts Molding starts from the initial design phase, where we collaborate closely with clients to optimize part structures for molding feasibility. Unlike generic service providers, we understand that every detail in Plastic Chair Parts Molding—from material selection to mold temperature control—impacts the final product’s performance. Whether it’s armrests, seats, or leg supports, our tailored Plastic Chair Parts Molding processes ensure consistent quality across batches, making us a trusted partner for furniture brands worldwide. This focus on the core process has not only strengthened our market position but also enabled us to build long-term relationships with clients who value reliability in Plastic Chair Parts Molding

Send Inquiry

For Plastic Chair Parts Molding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 12 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

P&M Plastic Chair Parts Molding Introduction

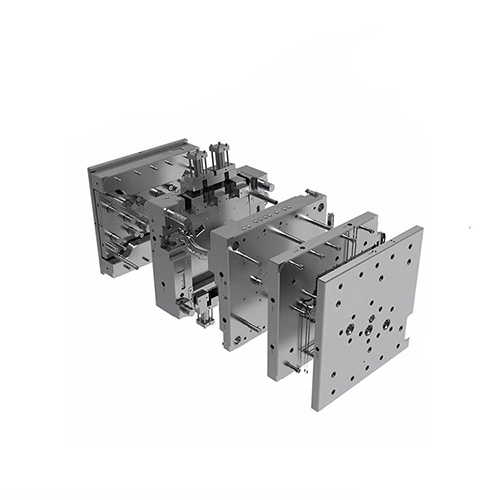

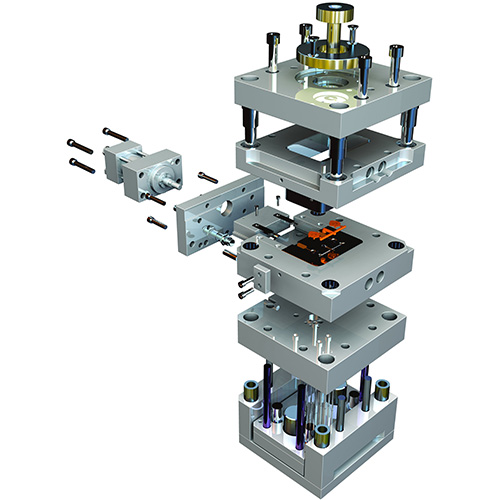

Plastic Chair Parts Molding, at its essence, is an injection molding process that transforms raw plastic materials into precise, functional components for plastic chairs. This process involves feeding plastic pellets into an injection molding machine, where they are heated to a molten state, then injected under high pressure into a custom-designed mold cavity. Once cooled and solidified, the mold opens to release the finished plastic chair part—be it a seat panel, backrest, leg, or connecting bracket. What makes Plastic Chair Parts Molding stand out is its ability to produce high-volume, consistent parts with complex geometries, a key requirement for the mass production of plastic chairs.

As a leading injection molding manufacturer, P&M brings unique insights to Plastic Chair Parts Molding that set us apart from competitors. First, our mold design team specializes in creating molds tailored explicitly for Plastic Chair Parts Molding. We leverage 3D modeling and simulation tools to test mold designs before production, identifying potential issues such as uneven cooling or material flow that could compromise part quality. This proactive approach reduces mold rework and shortens lead times, a critical advantage for clients looking to launch products quickly.

Material selection is another cornerstone of effective Plastic Chair Parts Molding, and P&M’s expertise here is unparalleled. We work with a wide range of thermoplastics, including PP (polypropylene), HDPE (high-density polyethylene), and ABS, each chosen based on the specific requirements of the chair part. For example, PP is ideal for seat and backrest parts due to its durability and flexibility, while ABS is used for structural components like leg supports thanks to its high impact resistance. Our team guides clients through material selection, ensuring that each part produced via Plastic Chair Parts Molding meets the desired strength, weight, and aesthetic standards.

The equipment we use for Plastic Chair Parts Molding further reinforces our capabilities. P&M has invested in a fleet of advanced injection molding machines with clamping forces ranging from 50 to 500 tons, capable of handling parts of all sizes—from small connecting pins to large seat panels. Each machine is equipped with precision temperature control systems and automated part ejection, ensuring that every part produced through Plastic Chair Parts Molding adheres to tight tolerances. Our quality control team also conducts rigorous inspections at every stage of Plastic Chair Parts Molding, using coordinate measuring machines (CMMs) and visual inspection tools to verify dimensions and surface quality.

Moreover, P&M’s approach to Plastic Chair Parts Molding is rooted in sustainability, a growing concern for modern manufacturers. We optimize material usage to minimize waste, recycling excess plastic from the molding process and incorporating recycled materials where possible without sacrificing quality. This not only reduces environmental impact but also lowers material costs for our clients, making our Plastic Chair Parts Molding services more cost-effective in the long run. By combining technical expertise, advanced equipment, and a focus on sustainability, P&M has redefined what clients can expect from a partner in Plastic Chair Parts Molding.

P&M Plastic Chair Parts Molding(Specification)

|

Mould Name |

Plastic Chair Parts Molding |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Plastic Chair Parts Molding Feature And Application

Plastic Chair Parts Molding boasts a suite of features that make it the preferred process for producing plastic chair components, and P&M’s execution of these features elevates our services to meet the most demanding client needs. One of the primary features of Plastic Chair Parts Molding is high precision and consistency. Injection molding technology allows for tight tolerances—often within 0.01mm—ensuring that every chair part fits together seamlessly during assembly. For P&M, this precision is not just a technical specification but a promise: our Plastic Chair Parts Molding processes deliver parts that require minimal post-processing, reducing assembly time and costs for our clients.

Another key feature of Plastic Chair Parts Molding is versatility. The process can accommodate a wide range of part designs, from simple flat seats to complex, ergonomic backrests with integrated lumbar support. P&M leverages this versatility to support clients across various market segments, including residential furniture, commercial office furniture, and outdoor patio furniture. For example, outdoor chair parts require resistance to UV radiation and moisture, so we adjust our Plastic Chair Parts Molding parameters—such as material additives and cooling times—to enhance these properties. Similarly, office chair parts need to withstand repeated use, so we optimize mold design to reinforce stress points, ensuring long-term durability.

Cost-effectiveness at scale is a third defining feature of Plastic Chair Parts Molding. While the initial investment in custom molds may seem significant, the low per-unit cost of injection molding makes it ideal for high-volume production. P&M maximizes this cost advantage by optimizing mold cycles—reducing the time it takes to produce each part through efficient heating and cooling systems. Our automated production lines also minimize labor costs, allowing us to offer competitive pricing for Plastic Chair Parts Molding without compromising quality. For clients producing tens of thousands of chairs annually, this translates to substantial cost savings that boost their bottom line.

The applications of Plastic Chair Parts Molding are vast and varied, spanning nearly every type of plastic chair on the market, and P&M’s expertise covers them all. Residential plastic chairs, such as dining chairs and kids’ chairs, rely on Plastic Chair Parts Molding for safe, lightweight, and affordable components. We produce rounded, burr-free parts for kids’ chairs to ensure safety, and use food-grade materials for dining chair parts that may come into contact with food. Commercial settings, such as restaurants and conference halls, demand chairs that are durable and easy to clean—our Plastic Chair Parts Molding processes deliver parts with smooth surfaces and high chemical resistance, meeting these requirements.

Outdoor furniture is another key application area for Plastic Chair Parts Molding, and P&M has developed specialized solutions for this segment. Outdoor chairs are exposed to harsh weather conditions, so we use UV-stabilized materials and modify our molding processes to prevent cracking or fading. Our Plastic Chair Parts Molding for outdoor chairs also includes features like drainage holes in seats, designed during the mold design phase to enhance functionality. Additionally, we cater to the hospitality industry, producing custom-designed chair parts via Plastic Chair Parts Molding that align with brand aesthetics—from colored armrests to branded backrests.

What truly sets P&M apart in the application of Plastic Chair Parts Molding is our customer-centric approach. We don’t just produce parts; we partner with clients to understand their unique needs and tailor our Plastic Chair Parts Molding services accordingly. Whether a client needs a prototype for a new chair design or high-volume production for a global launch, we have the capabilities to deliver. Our dedicated account managers ensure clear communication throughout the process, from initial design to final delivery, and our after-sales support team addresses any issues promptly. We also offer competitive pricing and flexible lead times, making us the go-to choice for Plastic Chair Parts Molding.

In conclusion, Plastic Chair Parts Molding is an indispensable process for the plastic furniture industry, and P&M’s expertise in this field makes us the ideal partner for manufacturers worldwide. Our focus on precision, versatility, and cost-effectiveness, combined with our commitment to sustainability and customer service, ensures that every project we undertake meets the highest standards. Whether you’re looking to optimize your existing Plastic Chair Parts Molding processes or launch a new product, we invite you to contact P&M today to discuss your needs and request a quote. Let us help you bring your plastic chair designs to life with exceptional Plastic Chair Parts Molding solutions.

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.