- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Plastic crib parts moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize plastic crib parts moulding. We provide professional customized plastic crib parts moulding services, and we are a professional plastic crib parts moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing plastic crib parts moulding, our factory can provide one-stop service. We have design and production capabilities related to plastic crib parts moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized plastic crib parts moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For plastic crib parts moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

Crib parts are directly related to the safety of infants and toddlers, so their production process has extremely high requirements for safety, environmental protection and quality consistency. The entire process is based on the general injection molding process and has stricter control standards.

The following is the detailed forming process:

Phase One: Safety Compliance and Design

This is the foundation of all work and is more crucial than ordinary products.

Safety standard confirmation: Firstly, it is necessary to clearly define the safety standards for cribs in the target market (such as China GB, the United States ASTM F1169, the European Union EN 716, etc.). These standards have mandatory regulations on the mechanical and physical properties (strength, durability), flame retardancy, and the content of chemical substances (such as phthalates, heavy metals) of parts.

Material selection

Preferred material: It must be food-grade or medical-grade plastic, such as PP (polypropylene), HDPE (high-density polyethylene). These materials are non-toxic, odorless, chemically stable, impact-resistant and easy to clean.

Core requirements: Only brand new materials must be used. The use of recycled materials or waste of unknown origin is strictly prohibited. Raw material suppliers are required to provide relevant food safety certifications (such as FDA, LFGB) and material certificates.

Product and Mold Design

Safety structure: When designing, any sharp edges and points that may cause pinching or scratching should be avoided. All corners and edges should be rounded.

Structural strength: Ensure the strength of load-bearing components such as guardrails and bed plates through reasonable reinforcement rib design, and simulate the force conditions through CAE analysis.

Mold design: The design of the runner, cooling and exhaust systems of the mold should aim at minimizing defects to the greatest extent. The steel for molds must be of high quality to ensure the stability of long-term production and the smoothness of the parts' surfaces, and to prevent dirt and grime from accumulating.

Phase Two: Strict pre-production preparations

Raw material pretreatment

Strict drying of materials: Even new materials must be dried strictly in accordance with the material supplier's recommendations (for example, PP should be dried at 80-100℃ for 2-3 hours) to remove trace amounts of moisture and prevent the product from developing bubbles or silver streaks.

Specialized barrel: The equipment should be dedicated or thoroughly cleaned to prevent contamination by raw materials of different colors or types.

Equipment and Environmental preparation

Injection molding machine cleaning: Ensure that the injection molding machine's barrel and screw are extremely clean, free of any residual materials from previous production.

Cleanroom: The production environment is best to meet the standards of a dust-free workshop to prevent dust from settling on the product surface.

Phase Three: Core injection Molding process

This stage is similar to the general process, but the parameter control is more precise.

Feeding: Feed the dried pure raw materials into the hopper of the injection molding machine.

Plasticizing: Solid particles are transformed into a molten state through heating and screw shearing. Temperature control must be precise to prevent material degradation due to excessively high temperatures.

Injection and pressure holding: Molten plastic is injected into the mold cavity and subjected to sufficient pressure holding to prevent product shrinkage and ensure dimensional stability and structural compactness.

Cooling and mold opening: After cooling and setting in the mold, the mold is opened.

Automated pick-up: Use mechanical arms to pick up items to avoid product contamination or scratches caused by manual contact.

Phase Four: Post-processing and secondary processing

Gate removal: Remove the sprue material from the part. After removal, it must be ensured that there are no burrs or sharp edges. Usually, special fixtures or equipment are required for trimming.

Necessary assembly: If the crib is composed of multiple plastic parts, ultrasonic welding or mechanical snap-on assembly may be carried out. Welding must ensure strength and the welding area should be smooth without sharp corners.

Phase Five: Comprehensive Quality Inspection (Extremely important!)"

This is the core link to ensure the safety of the crib, usually involving online inspection and offline spot checks.

First piece inspection: After each shift starts up or changes the mold/material, conduct a comprehensive measurement and inspection of the products from the first few molds produced.

Online inspection: Quality inspectors regularly (such as every hour) take products from the production line for inspection.

Inspection content

Appearance inspection: Whether the surface is smooth, whether the color is uniform, and whether there are defects such as shrinkage, bubbles, scratches, stains, and burrs.

Dimensional inspection: Tools such as calipers and three-coordinate measuring machines are used. Critical dimensions must 100% conform to the tolerances of the drawings.

Functional inspection: Check whether the clips, sliding parts, etc. are assembled smoothly and function normally.

Special safety inspection

Sharp point and edge test: Use professional instruments (such as sharp point and edge testers) to inspect all accessible parts.

Small component test: Simulate a child pulling to ensure no small components fall off and prevent the risk of suffocation.

Strength testing: Regularly conduct load-bearing, impact and durability tests on the products (such as simulating children jumping and shaking guardrails multiple times).

Traceability: Each batch of products and even parts should have traceable labels (such as date codes, batch numbers), so that in case of problems, the raw materials, production machines and shifts can be quickly traced back.

Phase 6: Packaging and Warehousing

Cleaning: The parts may need to be cleaned before packaging to remove the dust adsorbed by static electricity.

Individual packaging: Each important part is usually individually packaged in a PE bag or bubble wrap to prevent scratches during transportation.

Marking and Warehousing: The product name, part number, production date, material and other information should be clearly marked on the packaging box. Qualified products should be wareited for shipment.

We are a plastic crib parts moulding manufacturer, providing high-quality plastic crib parts moulding manufacturing. As long as you want to customize/develop plastic crib parts moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

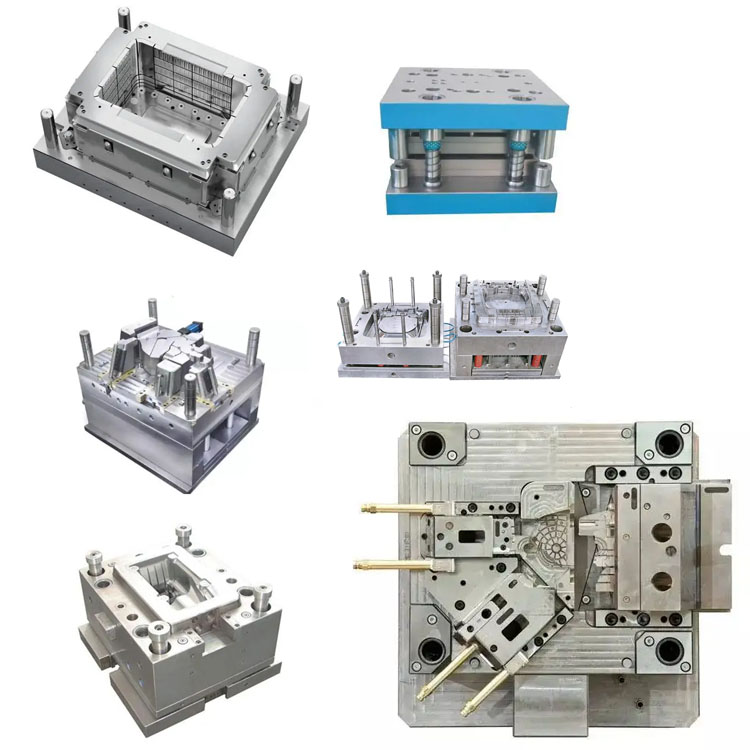

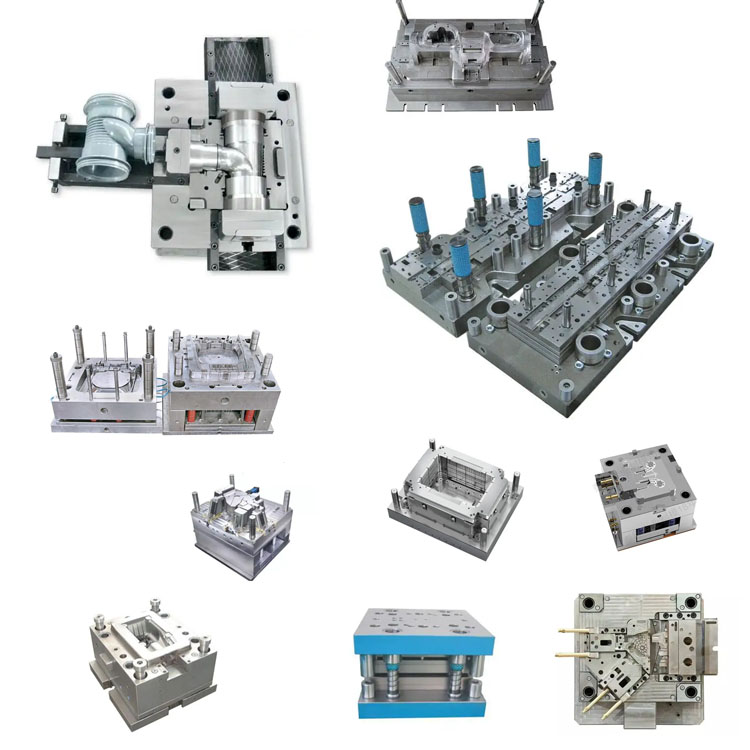

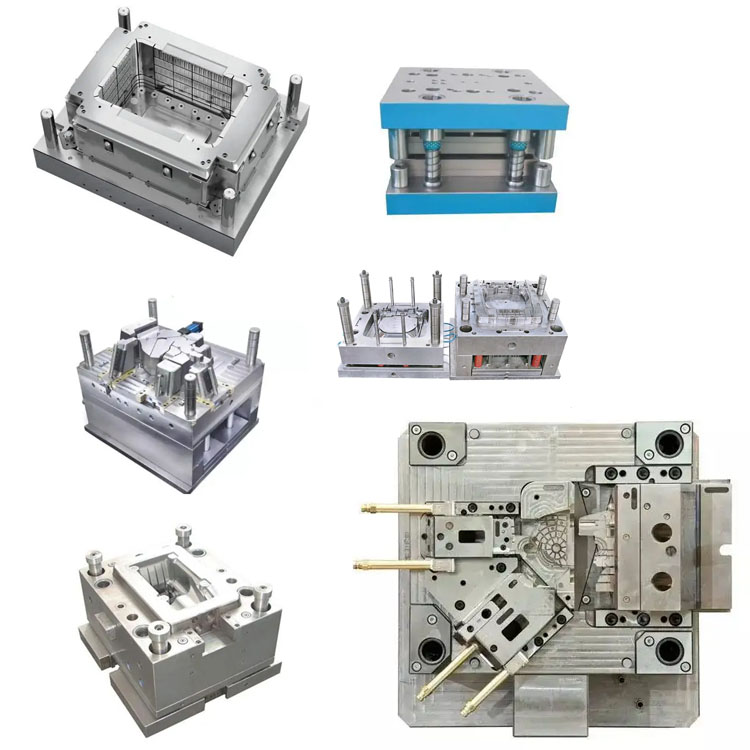

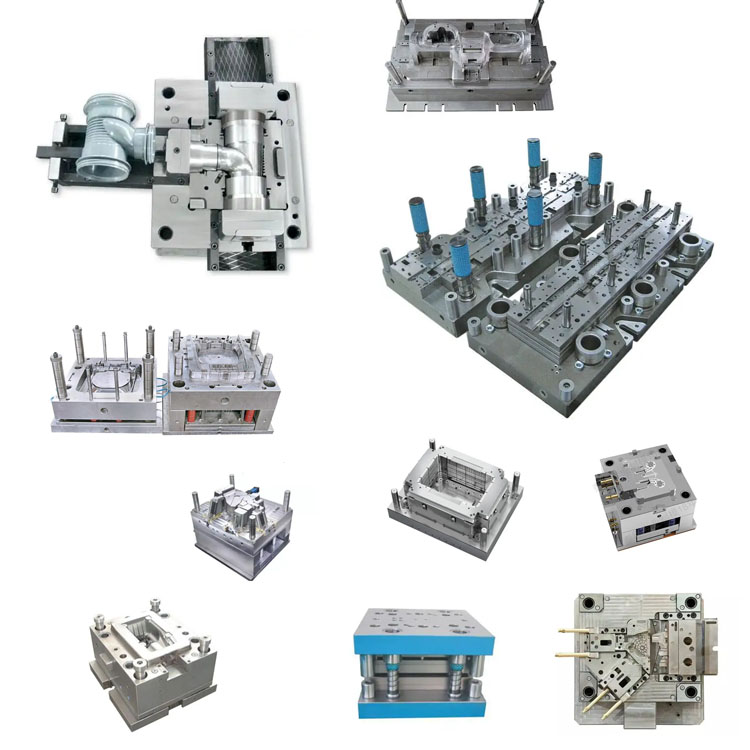

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.