- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

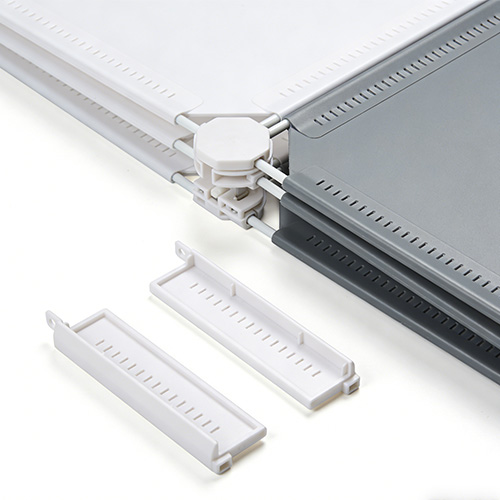

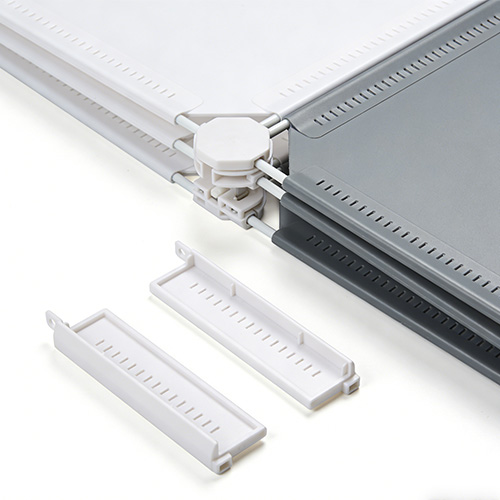

Plastic Foldable Wardrobe Parts Molding

Plastic Foldable Wardrobe Parts Molding is the core process that determines the quality, durability and usability of plastic foldable wardrobe parts, and it is also a key field where P&M, as a professional injection mold manufacturer, has concentrated its strengths for years. For customers who focus on the production of plastic foldable wardrobes, the precision and stability of Plastic Foldable Wardrobe Parts Molding directly affect the final product's market competitiveness. P&M has always taken optimizing Plastic Foldable Wardrobe Parts Molding as its core goal, integrating advanced mold design concepts and mature injection molding technologies to provide customers with one-stop solutions from mold development to parts molding. Whether it is the molding of load-bearing components or the shaping of connecting parts, P&M's Plastic Foldable Wardrobe Parts Molding technology ensures that each part meets strict quality standards, laying a solid foundation for customers to create high-quality wardrobes. With rich experience in this field, P&M has become a trusted partner for many wardrobe manufacturers, relying on excellent Plastic Foldable Wardrobe Parts Molding capabilities to help customers reduce production costs and improve market response speed

Send Inquiry

For Plastic Foldable Wardrobe Parts Molding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 12 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

P&M Plastic Foldable Wardrobe Parts Molding Introduction

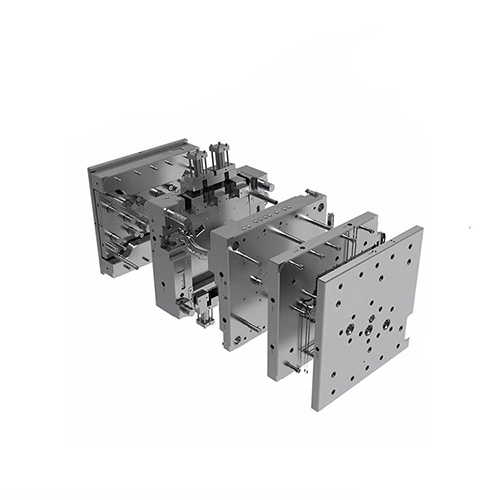

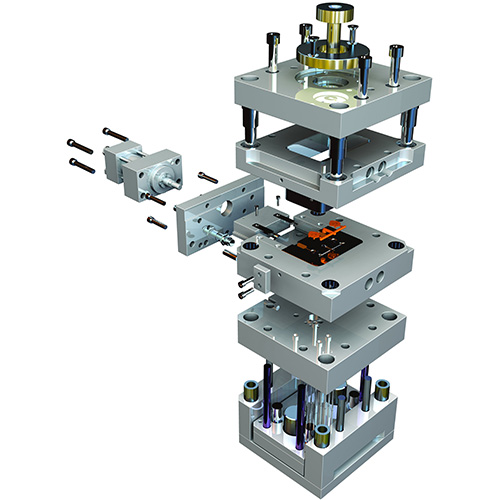

Plastic Foldable Wardrobe Parts Molding is a specialized injection molding process tailored for the production of various components of plastic foldable wardrobes, covering the entire process from raw material selection, mold design and manufacturing to injection molding production, quality inspection and post-processing. As a professional injection mold manufacturer, P&M has a deep understanding of the technical connotations of Plastic Foldable Wardrobe Parts Molding and has built a complete process system around it. The first step of Plastic Foldable Wardrobe Parts Molding is raw material customization. P&M does not adopt a one-size-fits-all approach but selects high-quality polypropylene (PP) or ABS materials with appropriate toughness and strength according to the functional requirements of different parts (such as load-bearing shelves, foldable brackets, and connecting buckles). These materials are not only environmentally friendly and non-toxic but also have excellent impact resistance and wear resistance, ensuring that the molded parts can withstand repeated folding and long-term use. The core link of Plastic Foldable Wardrobe Parts Molding lies in mold design and manufacturing, which is also the core advantage of P&M. The company's R&D team has more than 15 years of experience in mold design for plastic furniture parts. They use 3D modeling software (such as UG and SolidWorks) to carry out precise design for Plastic Foldable Wardrobe Parts Molding. According to the structural characteristics of foldable parts, they reasonably set the gate position, cooling system and demolding mechanism to avoid problems such as warping, shrinkage and uneven wall thickness of the molded parts. In the mold manufacturing process, P&M adopts high-precision CNC machining centers and EDM equipment, with a machining accuracy of up to ±0.005mm, ensuring that each mold cavity meets the design requirements of Plastic Foldable Wardrobe Parts Molding. After the mold is completed, P&M will conduct a trial molding test to adjust parameters such as injection speed, temperature and pressure to optimize the Plastic Foldable Wardrobe Parts Molding process. During the formal production stage, the company uses fully automated injection molding production lines, which can realize continuous production of 24 hours a day. The production process is monitored in real time by IoT technology, and key parameters such as temperature and pressure are recorded in real time to ensure the consistency of each batch of parts. In addition, P&M has established a strict quality inspection system for Plastic Foldable Wardrobe Parts Molding. Each batch of parts will undergo dimensional inspection (using a three-coordinate measuring instrument), impact resistance test and folding fatigue test to ensure that the products meet international quality standards. Compared with other manufacturers, P&M's Plastic Foldable Wardrobe Parts Molding process has obvious advantages in customization. The company can quickly respond to customers' personalized needs, whether it is adjusting the size of parts, changing the color of materials or optimizing the folding structure, it can complete the mold modification and process adjustment in the shortest time, helping customers launch new products faster. This flexible response capability is based on P&M's deep accumulation in Plastic Foldable Wardrobe Parts Molding and the perfect collaboration between the R&D team and the production team.

Another key point of Plastic Foldable Wardrobe Parts Molding is the integration of environmental protection concepts, which is also an important part of P&M's development strategy. In the process of raw material procurement, P&M strictly selects suppliers that meet environmental protection standards and uses recyclable materials as much as possible to reduce environmental pollution. In the Plastic Foldable Wardrobe Parts Molding process, the company optimizes the injection molding parameters to reduce material waste and energy consumption. The waste generated during production will be recycled and processed through professional equipment, and then reused after meeting the quality requirements, realizing the recycling of resources. This environmentally friendly production method not only conforms to the global green development trend but also helps customers reduce raw material costs, enhancing the market competitiveness of their products. For customers who pay attention to environmental protection, P&M's environmentally friendly Plastic Foldable Wardrobe Parts Molding solution is undoubtedly a key factor in choosing cooperation. In addition, P&M provides customers with technical support throughout the entire process of Plastic Foldable Wardrobe Parts Molding. From the early stage of product design, the company's technical team will communicate with customers in depth to put forward reasonable suggestions on the structural optimization of parts to improve the moldability of parts and reduce production risks. During the production process, if customers encounter technical problems, P&M's after-sales service team can respond within 24 hours and provide on-site guidance or remote technical support to ensure the smooth progress of customers' production. This full-process service model makes P&M's Plastic Foldable Wardrobe Parts Molding service more comprehensive and humanized, winning the trust of a large number of long-term customers.

P&M Plastic Foldable Wardrobe Parts Molding(Specification)

|

Mould Name |

Plastic Foldable Wardrobe Parts Molding |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Plastic Foldable Wardrobe Parts Molding Feature And Application

Plastic Foldable Wardrobe Parts Molding, as a specialized injection molding process, has a series of unique features that make it highly adaptable to the production needs of plastic foldable wardrobe parts, and these features are fully exerted and optimized in P&M's production system. The first prominent feature of Plastic Foldable Wardrobe Parts Molding is high precision and good consistency. Due to the foldable nature of the wardrobe, the matching accuracy between parts (such as the connection between the bracket and the panel, the fit between the hinge and the side plate) is extremely high. If the dimensional error is too large, it will lead to difficult folding, loose connection or even inability to assemble. P&M's Plastic Foldable Wardrobe Parts Molding uses high-precision molds and automated production lines to control the dimensional error of each part within ±0.01mm, ensuring that the parts can be perfectly matched during assembly. At the same time, the automated production process avoids the influence of human factors on product quality, making the pass rate of each batch of parts reach more than 99.5%, greatly reducing the rework rate and waste of customers. The second feature is strong customization and good flexibility. Different customers have different market positioning and product design requirements, such as wardrobes of different sizes, styles and colors, which require corresponding adjustments to the parts. P&M's R&D team can quickly design and manufacture molds suitable for different needs according to customers' drawings or samples, and adjust the Plastic Foldable Wardrobe Parts Molding process in a targeted manner. For example, for customers who need to produce small foldable wardrobes for dormitories, P&M will choose lighter and more flexible materials and optimize the mold structure to reduce the weight of parts; for customers who focus on outdoor foldable wardrobes, the company will use materials with better weather resistance and adjust the injection molding temperature to enhance the UV resistance of parts. This strong customization capability enables P&M's Plastic Foldable Wardrobe Parts Molding service to meet the personalized needs of different customers. The third feature is high production efficiency and low cost. P&M has introduced more than 50 sets of advanced injection molding machines with clamping forces ranging from 50T to 500T, which can meet the molding needs of parts of different sizes. The automated production line can realize automatic feeding, injection molding, demolding and inspection, and the production cycle of a single part is shortened by 30% compared with the traditional manual operation mode. At the same time, the high-precision molds manufactured by P&M have a long service life, with an average service life of more than 1 million shots, which greatly reduces the mold replacement cost of customers. In addition, the company's large-scale procurement of raw materials and optimized production process also help reduce the unit cost of parts. Therefore, P&M's Plastic Foldable Wardrobe Parts Molding can provide customers with high-quality products while effectively controlling production costs, enhancing the price advantage of customers' products in the market.

The application scope of Plastic Foldable Wardrobe Parts Molding is closely related to the components of plastic foldable wardrobes, and P&M's molding technology covers all core parts, providing comprehensive support for customers' production. One of the main application areas is the molding of load-bearing parts, such as wardrobe shelves, bottom brackets and vertical poles. These parts need to have sufficient strength to bear the weight of clothes and other items. P&M's Plastic Foldable Wardrobe Parts Molding uses reinforced materials and optimizes the mold's gating system to ensure that the materials are evenly filled in the mold cavity, improving the structural strength of the parts. The load-bearing shelves molded by this process can bear a weight of more than 30kg without deformation, meeting the practical needs of customers. The second application area is the molding of foldable connecting parts, such as hinges, rotating shafts and buckles. These parts are the core of the wardrobe's foldable function, requiring good flexibility and wear resistance. P&M's R&D team has specially designed a multi-cavity mold for the molding of these parts, and adjusted the injection molding speed and pressure to ensure that the surface of the parts is smooth and the rotation is flexible. After 10,000 folding tests, the connecting parts still maintain good performance without damage or jamming. The third application area is the molding of decorative and auxiliary parts, such as wardrobe panels, door handles and edge strips. These parts have high requirements for appearance and texture. P&M's Plastic Foldable Wardrobe Parts Molding uses high-gloss molds and adds color masterbatches to the raw materials to realize one-time molding of parts with different colors and textures, avoiding the need for subsequent painting or printing processes, reducing production links and improving production efficiency. The decorative panels molded by this process have a smooth surface, uniform color and no burrs, enhancing the overall aesthetics of the wardrobe. In addition to the above application areas, P&M's Plastic Foldable Wardrobe Parts Molding technology can also be extended to the production of parts for other foldable plastic furniture, such as foldable shoe racks, foldable storage boxes and other products, providing customers with a broader cooperation space.

As a professional injection mold manufacturer, P&M's advantages in Plastic Foldable Wardrobe Parts Molding are not only reflected in technology and process but also in the overall service and market support for customers. The company has a professional sales team that can communicate with customers in multiple languages, understand customer needs in a timely manner and provide detailed project plans. In terms of delivery time, P&M has a complete production scheduling system, which can ensure that the mold manufacturing and parts production are completed on time and delivered to customers through cooperative logistics companies with global coverage. For customers who have urgent orders, the company can start the emergency production mechanism to shorten the delivery cycle as much as possible. In addition, P&M regularly provides customers with technical training on Plastic Foldable Wardrobe Parts Molding, introducing the latest process technologies and quality control methods to help customers improve their own production levels. Whether you are a large-scale wardrobe manufacturer with mass production needs or a small and medium-sized enterprise with personalized customization requirements, P&M's Plastic Foldable Wardrobe Parts Molding service can meet your needs. We sincerely invite you to contact us to consult the quotation and cooperate to create high-quality plastic foldable wardrobe products that are popular in the market.

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.