- Core Customization Service

- Health Care

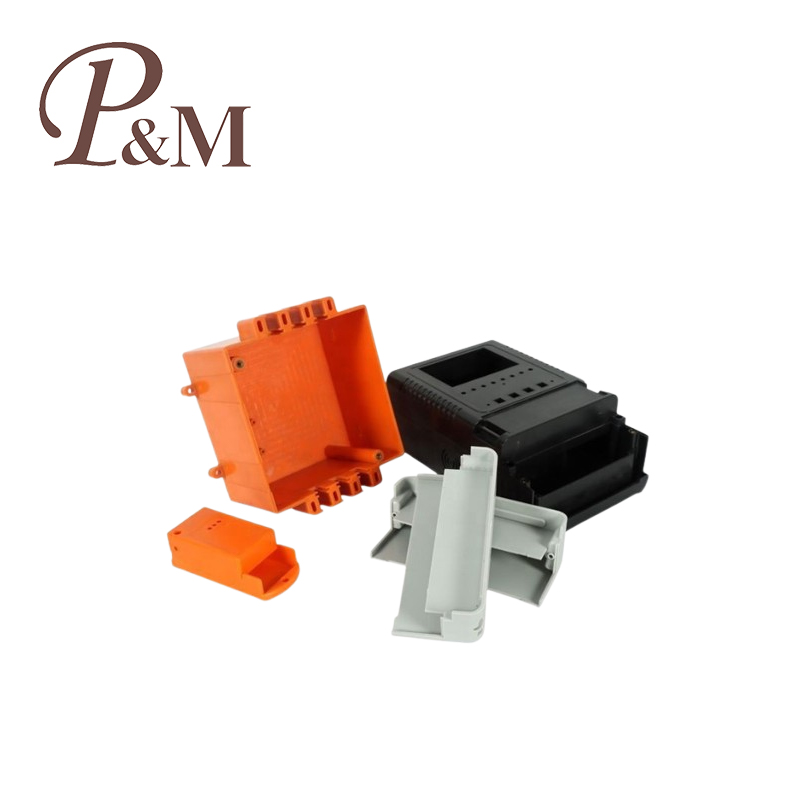

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Plastic injection molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Plastic injection molding. We have ISO 9001 certificates. We provide professional Plastic injection molding service and we are professional Plastic injection molding manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.

Send Inquiry

As a professional service provider focusing on high-precision Plastic injection molding (plastic forming), we are dedicated to delivering cost-effective custom plastic component manufacturing solutions to clients across global industries, while offering complementary professional component assembly services. With decades of technical proficiency refined in Plastic injection molding processes, precise mastery of plastic material properties, and a customer-oriented customization philosophy, we accurately address the complex production demands of sectors including automotive, electronics, medical devices, household appliances, and industrial equipment. Spanning from product structural design optimization, material selection consultation, and mass Plastic injection molding production to post-production component assembly, we construct a full-process, efficient, and collaborative service ecosystem for clients, empowering them to elevate their product competitiveness in the global market.

In the Plastic injection molding industry, customization capability serves as the paramount benchmark for evaluating a service provider’s core competitiveness. Our distinctive strength lies in delivering all-dimensional customization services—from product structural decomposition to precise material matching—tailored to clients’ specific application scenarios and performance indicators. We possess profound insights into the structural characteristics of products across diverse industries. Whether it involves electronic components with intricate internal cavities and precision snap-fit structures, industrial machinery plastic parts engineered to withstand high-strength loads, or household appliance exterior components demanding superior surface finish, we guarantee that the Plastic injection molding components align perfectly with client requirements through professional structural analysis and process optimization.

For the structural design and optimization of customized Plastic injection molding products, we have developed a sophisticated service workflow. In the preliminary phase of a project, our senior structural engineers engage in in-depth consultations with clients to comprehensively collate core parameters, such as the product’s operating environment, stress-bearing capacity, and assembly specifications. Integrating the technical characteristics of Plastic injection molding, we offer professional structural optimization proposals. For example, for spliced plastic components requiring tight assembly tolerances, we precisely design fitting clearances and positioning structures. By rationally setting draft angles and avoiding undercut structures, we not only ensure the assembly precision of the final product but also enhance production efficiency in the Plastic injection molding process. For plastic components of hydraulic systems featuring complex internal flow channels, we employ advanced simulation technology to optimize the flow channel structure, ensuring uniform melt filling during Plastic injection molding and eliminating defects like air bubbles and shrinkage marks. Furthermore, we support customized development of various structural modules, including main body structures, connection structures, reinforcing rib configurations, and sealing structures. Whether it is a complex integral-formed component or a multi-module part requiring post-molding assembly, we can tailor a targeted Plastic injection molding solution.

Accurate material selection is the cornerstone of ensuring the performance of Plastic injection molding products. Leveraging our extensive knowledge of the properties of various plastic materials and their compatibility with different Plastic injection molding processes, we provide clients with cost-effective material selection guidance. Currently, the plastic materials we support for Plastic injection molding cover general-purpose plastics, engineering plastics, special engineering plastics, and modified plastics, capable of meeting the diverse performance requirements of products in different application scenarios.

In the realm of general-purpose plastics for Plastic injection molding, we frequently utilize materials such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS). These materials exhibit advantages including low cost, excellent moldability, and high production efficiency in Plastic injection molding, making them ideal for products with relatively moderate performance demands, such as daily necessities, packaging components, and basic household appliance casings. For instance, polypropylene (PP) is widely employed in manufacturing food-contact plastic components due to its outstanding chemical resistance and heat resistance, which are well-suited to the high-temperature processing conditions of Plastic injection molding. Polyethylene (PE), with its superior toughness and impact resistance, is an optimal choice for producing packaging containers and daily-use plastic parts through Plastic injection molding. Polyvinyl chloride (PVC) boasts excellent chemical stability and flame retardancy, making it a preferred material for pipe fittings and decorative plastic components in Plastic injection molding production. Polystyrene (PS), characterized by good transparency and moldability, is suitable for manufacturing plastic toys and packaging trays via Plastic injection molding.

For engineering plastics, which are extensively applied in high-performance Plastic injection molding scenarios, we have accumulated rich practical experience with materials such as acrylonitrile-butadiene-styrene (ABS), polycarbonate (PC), nylon (PA), and polyoxymethylene (POM). Compared to general-purpose plastics, these materials offer superior mechanical properties, heat resistance, and chemical stability, making them suitable for manufacturing core components in automotive, electronics, and industrial equipment industries through Plastic injection molding. ABS plastic, with its excellent impact resistance and surface gloss, is a top choice for producing automotive interior parts and electronic product casings via Plastic injection molding. Polycarbonate (PC) exhibits exceptional impact resistance and high-temperature resistance, and is widely used in manufacturing electronic product housings and medical device components that require high transparency and strength through Plastic injection molding. Nylon (PA), renowned for its excellent wear resistance and mechanical strength, is ideal for producing gears, bearings, and other transmission components in industrial equipment via Plastic injection molding. Polyoxymethylene (POM), with its good fatigue resistance and dimensional stability, is commonly used in manufacturing precision mechanical parts such as fasteners and sliding components through Plastic injection molding.

For special engineering plastics designed to withstand extreme environments in Plastic injection molding applications, we also provide professional adaptation services, covering materials such as polytetrafluoroethylene (PTFE), polyetheretherketone (PEEK), and polysulfone (PSU). These materials possess exceptional high-temperature resistance, corrosion resistance, and mechanical properties, making them suitable for key components in aerospace, medical, and high-end industrial fields produced via Plastic injection molding. For example, polytetrafluoroethylene (PTFE) features excellent high-temperature resistance and chemical inertness, and is used in manufacturing sealing components for high-temperature and corrosive environments through Plastic injection molding. Polyetheretherketone (PEEK) can maintain stable performance at temperatures up to 260°C and has good biocompatibility, making it a critical material for manufacturing medical implant components and aerospace parts via Plastic injection molding. Polysulfone (PSU) offers excellent transparency and high-temperature resistance, and is suitable for manufacturing high-precision electronic components and medical equipment housings through Plastic injection molding.

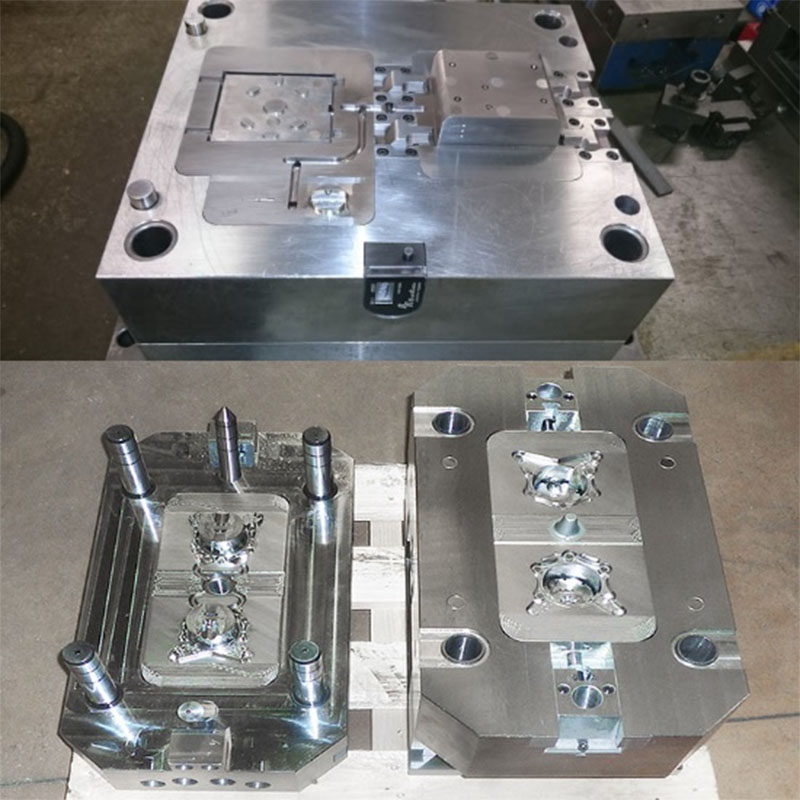

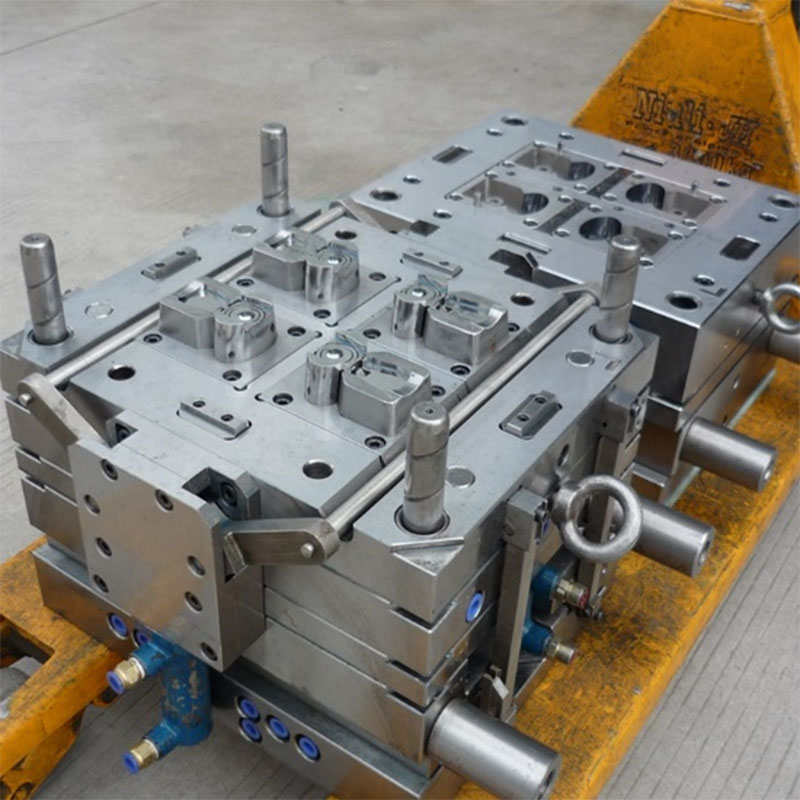

Our professional Plastic injection molding process system is the key to ensuring product quality and production efficiency. We adhere to stringent process standards and implement full-process quality control, spanning from mold design and manufacturing to finished product inspection. In the mold design stage for Plastic injection molding, we utilize advanced 3D modeling and simulation software to conduct mold flow analysis, predicting potential issues such as melt filling, cooling, and warpage during the Plastic injection molding process. This enables us to pre-optimize the mold structure, including runner design, gate position, and cooling system layout, ensuring mold rationality and laying a solid foundation for subsequent production. Our mold manufacturing team comprises experienced technicians who use high-precision processing equipment to fabricate mold cores, cavities, and other key components, ensuring that mold precision meets the requirements of customized Plastic injection molding products. Typically, the mold precision we can achieve reaches ±0.01mm, fully satisfying the production needs of precision plastic components via Plastic injection molding.

In the Plastic injection molding production phase, we are equipped with a comprehensive range of injection molding machines with clamping forces ranging from 50 tons to 1000 tons, capable of meeting the production needs of plastic components of varying sizes and weights. All Plastic injection molding machines are equipped with advanced intelligent control systems that can precisely regulate key process parameters, such as injection speed, injection pressure, holding pressure, and cooling time. During production, our technicians monitor these parameters in real-time to ensure consistent product quality. For example, when producing thin-walled plastic components via Plastic injection molding, we appropriately increase the injection speed to ensure rapid melt filling of the mold cavity; when manufacturing thick-walled components, we optimize holding pressure and cooling time to avoid defects like sink marks and shrinkage. Simultaneously, we implement a strict raw material management system for Plastic injection molding. Prior to production, all raw materials undergo rigorous inspection, including material composition, moisture content, and melt flow rate, to ensure they meet Plastic injection molding requirements. For moisture-absorbent materials such as nylon (PA) and polycarbonate (PC), we perform pre-drying treatment to prevent defects like bubbles in the final Plastic injection molding products.

Beyond Plastic injection molding production, we also offer professional component assembly services to fulfill clients’ one-stop production needs. Our assembly workshop is equipped with specialized assembly equipment and testing tools, and has established standardized assembly processes tailored to the characteristics of Plastic injection molding components. Based on the assembly requirements of different products, we provide services such as screw fastening, snap-fit assembly, adhesive bonding, and terminal crimping. During the assembly process, we implement strict process inspections to ensure assembly precision and product performance meet client specifications. For example, when assembling electronic components produced via Plastic injection molding, we use anti-static tools and work environments to prevent damage to sensitive electronic parts; when assembling mechanical components, we use precision testing instruments to inspect assembly gaps and rotational flexibility, ensuring the reliability of the assembled components. It is crucial to emphasize that our core focus is on providing high-quality Plastic injection molding components and supporting assembly services, rather than finished product manufacturing. This positioning allows us to concentrate our technical resources on enhancing the precision and performance of Plastic injection molding components, better catering to the professional needs of clients across various industries.

Quality control is an indispensable part of our Plastic injection molding service system. We have established a comprehensive quality management system covering the entire lifecycle from raw material incoming inspection, in-process inspection during Plastic injection molding, to finished product outgoing inspection. We are equipped with advanced testing equipment, including coordinate measuring machines (CMM) for dimensional inspection of Plastic injection molding products, tensile testing machines for evaluating material mechanical properties, melt flow rate testers for assessing material processability, and surface roughness testers for inspecting product surface quality. During production, our quality inspectors conduct random sampling and full inspections in accordance with sampling plans to ensure each batch of Plastic injection molding products meets quality standards. For non-conforming products, we implement a strict traceability system to analyze root causes and adopt corrective and preventive measures to avoid recurrence of similar issues.

We also prioritize the sustainability of our Plastic injection molding production and actively promote green manufacturing processes. We optimize Plastic injection molding processes to reduce energy consumption and material waste; simultaneously, we actively utilize recyclable plastic materials and promote the recycling and reuse of production scraps. We have obtained ISO9001 Quality Management System certification and ISO14001 Environmental Management System certification, demonstrating our unwavering commitment to quality and environmental protection in Plastic injection molding operations.

With years of experience in the Plastic injection molding industry, we have served hundreds of clients across diverse sectors and accumulated extensive project cases and technical expertise. Whether it is small-batch prototype trial production or large-scale mass production of Plastic injection molding components, we can provide flexible and efficient solutions. Our professional technical team and customer service team offer 24/7 technical support and after-sales service, promptly addressing any issues clients encounter during the cooperation process related to Plastic injection molding and assembly.

If you are seeking a reliable Plastic injection molding service provider specializing in custom plastic components and supporting assembly services, we are your ideal partner. Contact us today to share your product requirements, and our professional team will provide you with a customized Plastic injection molding solution and quotation. Let us collaborate to create high-quality plastic components and enhance your product’s competitiveness in the global market.

We are plastic mold maker and can provide custom mold service, we can make injection molds, blow molds, rotational molds and die-casting molds.

For custom injection molds, we can provide professional custom injection molding services. Usually Plastic injection mold manufacturing Molding are manufactured using injection molding technology. The mold materials for injection molds can be chosen from P20, 718, S136, H13 and so on. The mold material reflects the mold life and product material requirements.

For parts that require blow molding production, we can also provide professional custom blow molding services.

|

Product Name |

Plastic injection molding

|

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic injection mold manufacturing Injection Mould making

1.We communicate product design according to samples/drawings and your requirements.

2.After the product design is confirmed, we carry out the mold design, we provide all kinds of injection molds, blow molds, silicone molds, die-casting molds services.

3.Material procurement, steel cutting and mold basic tools.

4.Mold assembly

5.Mold inspection, tracking and controlling mold processing.

6. We will inform you the date of mold trial and send you the sample inspection report and injection parameters together with the sample.

7.Your instruction and confirmation of shipment.

8.Prepare the mold before packing.

Plastic injection mold manufacturing molding Specification

1. Professional manufacturer, design, production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Transaction process:

Mold testing:

Once the mold is complete, I do a mold test. It usually takes about 3-5 days to complete. We need to assemble the mold, adjust the pressure data of the machine, and try production. We need to check whether there are problems during the normal production of the mold and make modifications.

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

Factory

Video-1: (Factory Video)

Video-2: (Injection Molding)

Video-3: (Blow molding)

Video-4: (Blow molding)

Video-5: (Roll molding)

Customer satisfaction is our most important goal. We focus on communication and cooperation with our customers, always pay attention to their needs and provide quick response and quality customer service. Our injection production mold factory is committed to establishing long-term relationships and ensuring that our customers receive the best after-sales service during the purchase and use of our products, and we will definitely do our best to solve any problems for our customers.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us?

Mould,Plastic Product, Metal Product,Dental Product,CNC machining.

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6. What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.