- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

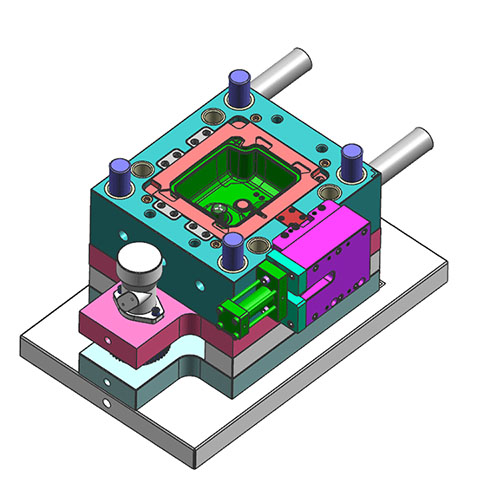

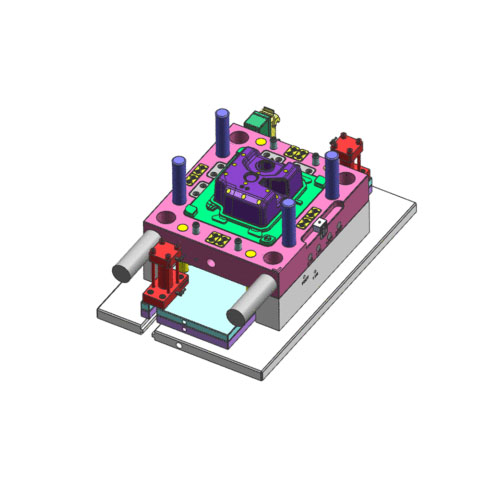

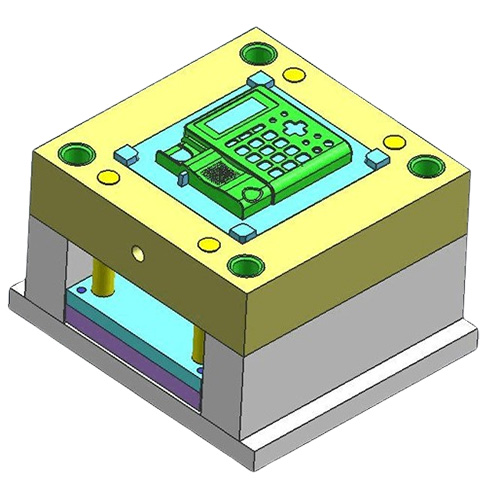

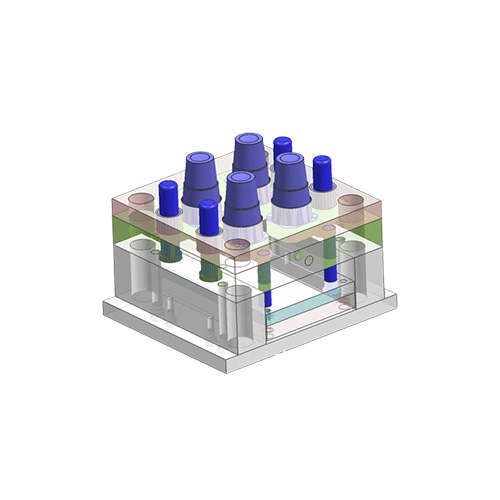

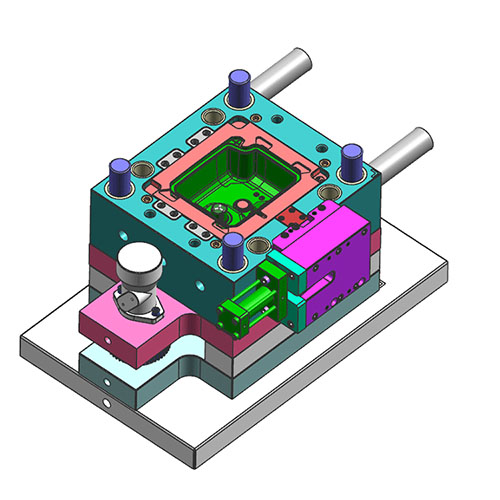

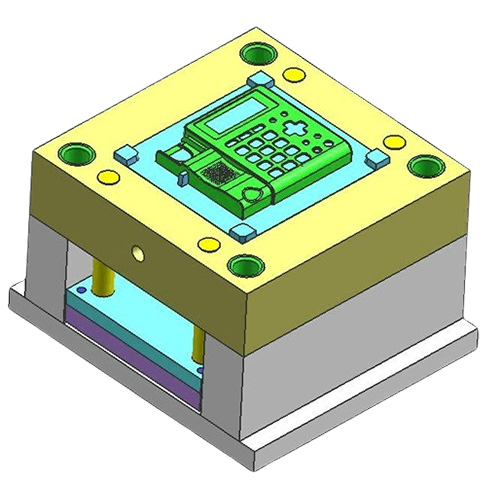

Plastic Injection Moulding Design

For Plastic Injection Moulding Design, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

Send Inquiry

In the field of plastic manufacturing, "design determines the upper limit of products", and plastic injection molding design, as the core link connecting product demand and mass production realization, directly affects the appearance, performance, cost, and production efficiency of products. It is not a single "mold design", but a systematic engineering that covers product structure design, mold structure design, and process parameter design - by avoiding molding defects (such as shrinkage marks, warping, and burrs) in advance, optimizing material and process matching, balancing functionality and manufacturability, and transforming abstract product concepts into high-quality plastic parts that can be mass-produced. Whether it is precision casings for consumer electronics or large structural components for automobiles, their mass production feasibility and quality stability depend on scientific and rigorous injection molding design.

Plastic injection molding design refers to the systematic planning and optimization of the structure of plastic products, the cavity/pouring system/cooling system/ejection system of injection molds, and injection process parameters (temperature, pressure, time) based on the characteristics of plastic materials (such as fluidity, shrinkage rate, thermal stability), injection molding process principles (heating and melting, high-pressure injection, cooling and solidification), and mass production requirements (efficiency, cost, consistency). Its core goal is to ensure that the product can be formed smoothly and without defects while meeting the requirements of product functionality (such as strength and sealing) and appearance, while maximizing mold life and optimizing production efficiency.

P&M Plastic Injection Moulding Design Introduction

1. Design confirmation and mold manufacturing: core preparation before production

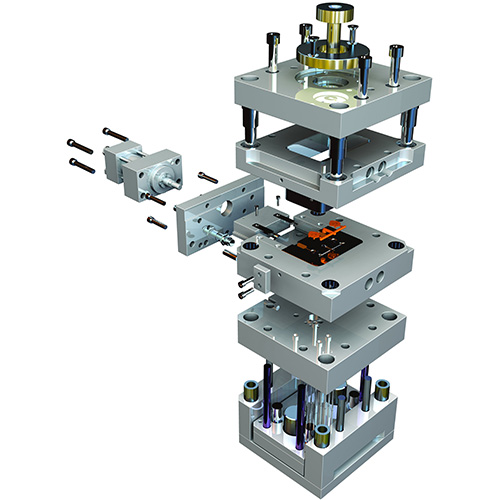

Before formal production, it is necessary to complete the three-step preparation of "design verification - mold manufacturing - trial mold optimization" to ensure that the design can be implemented:

Design review: The design scheme is jointly reviewed by product designers, mold designers, and process engineers, with a focus on checking whether the wall thickness is uniform, whether there is reverse buckling, and whether the pouring system is reasonable. If necessary, CAE software is used for simulation analysis (predicting filling time, shrinkage mark position, and warpage), and design defects are modified in advance (such as adding reinforcement bars or adjusting wall thickness if simulation shows shrinkage marks in a certain area);

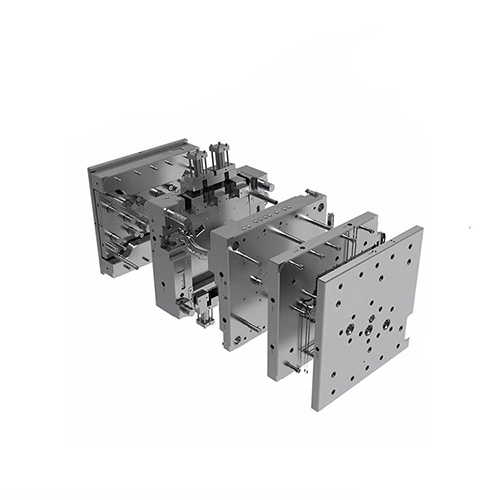

Mold manufacturing: Processing molds based on the final design drawings, with core processes including:

Mold cavity processing: CNC milling or electrical discharge machining are used to ensure that the mold cavity size is consistent with the design;

Surface treatment: polishing the surface of the mold cavity and coating if necessary;

Component assembly: Assemble the mold cavity, pouring system, cooling system, ejector system, and other components to ensure smooth operation of moving parts such as sliders and ejector pins;

Trial mold optimization: For the first trial mold (using a small amount of raw materials, such as 50-100 pieces), check for defects in the product (such as missing materials, flying edges, and shrinkage marks), and adjust the design based on the trial mold results:

If there is a shortage of materials: increase the gate size or increase the injection pressure;

If there are flying edges: reduce injection pressure or decrease mold clearance;

If there is warping: adjust the mold temperature (if one side is warped, increase the water temperature on that side) or optimize the wall thickness;

Trial molding usually requires 1-2 times until the product meets the quality requirements.

2. Raw material preparation: Material pretreatment adapted to the design

According to the designated plastic materials (such as PP, ABS, PMMA) in the design, targeted pretreatment is carried out to ensure stable material properties.

3. Injection molding: strictly following the core process of design parameters

The injection molding machine executes the "melting injection holding cooling demolding" process according to the designed process parameters, with the core being "precise control of parameters to ensure consistency in each product".

4. Post processing and testing: Ensure that design requirements are implemented

Perform post-processing and comprehensive testing on the demolded products, screen for non-conforming products, and ensure delivery quality.

P&M Plastic Injection Moulding Design(Specification)

|

Mould Name |

Plastic Injection Moulding Design |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Plastic Injection Moulding Design Feature And Application

1. In the field of consumer electronics: the ultimate pursuit of precision and appearance

Consumer electronic products (such as mobile phones, headphones, and computers) have extremely high requirements for "size accuracy, appearance texture, and lightweight", and injection molding design needs to focus on breakthroughs.

2. Automotive field: dual guarantee of weather resistance and structural strength

Automotive plastic parts (interior, exterior, functional parts) need to withstand "high and low temperatures, ultraviolet radiation, and impact", and the design core is "structural strength and weather resistance".

3. In the field of home appliances: balancing cost and functionality

Home appliances such as washing machines, air conditioners, and small appliances need to be "low-cost, easy to clean, and functionally practical", with the design core being "simplifying structure and controlling costs".

4. Medical field: strict standards for safety and precision

Medical plastic parts (such as syringes, infusion sets, and equipment casings) need to be "sterile, non-toxic, and high-precision", with the design core being "biocompatibility and sterilization".

5. Packaging field: Ultimate control of lightweight and cost

Packaging products (such as bottle caps, food boxes, and turnover boxes) need to be "mass produced, low-cost, and lightweight", with the design core being "simplifying processes and increasing output".

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.