- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

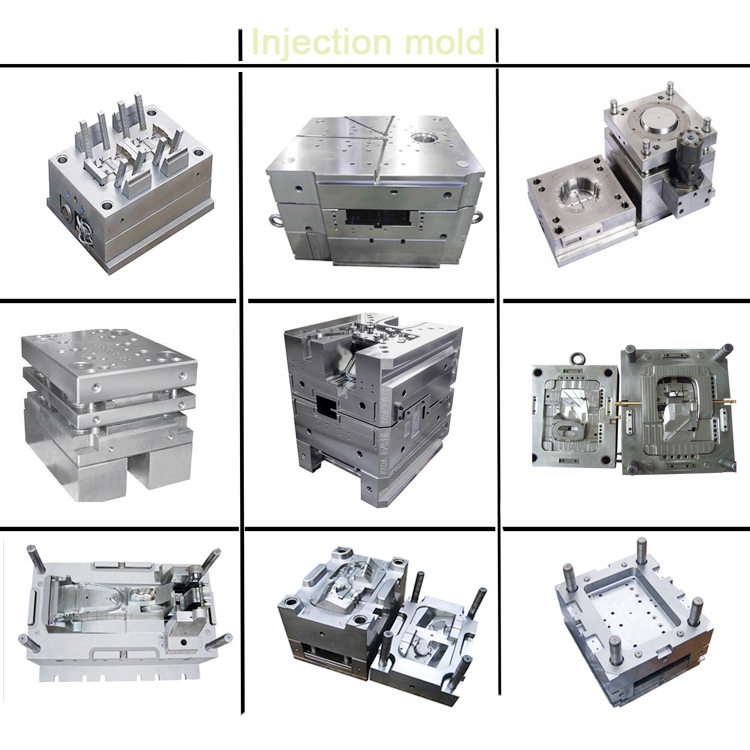

Plastic injection parts moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize plastic injection parts moulding. We provide professional customized plastic injection parts moulding services, and we are a professional plastic injection parts moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing plastic injection parts moulding, our factory can provide one-stop service. We have design and production capabilities related to plastic injection parts moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized plastic injection parts moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For plastic injection parts moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

Injection molding of plastic parts is an efficient and widely applied manufacturing process. Its core lies in rapidly and precisely replicating plastic raw materials into parts of the required shape through injection molding machines and molds. A complete and mature injection molding process is far more than just the "injection" step. It is a comprehensive system covering project management, engineering design, production and manufacturing, and quality management.

A complete and high-quality injection molding process follows a clear path from concept to delivery

Stop Two: Mold Design & Manufacturing

This is the core link in transforming design into physical tools. The quality of the mold directly determines the quality of the product.

Mold design

Moldflow analysis (Moldflow): Before mold opening, CAE software is used to simulate the filling, cooling, shrinkage and warpage of plastic in the mold. This can predict and address potential defects (such as cavitation, weld marks, and shrinkage) in advance, optimize the gate position, cooling system, and holding pressure strategy, and significantly reduce the cost and risk of mold testing.

Structural design: Design the mold base, cavity/core, slider (to handle lateral overturning), inclined top (to handle internal overturning), cooling water circuit, exhaust system, etc.

Mold processing and assembly

Precision machining: Core components such as mold cores and inserts are processed using processes like CNC (Numerical Control Milling), EDM (Electrical Discharge Machining), and wire cutting.

Surface treatment: Perform the required treatments on the cavity surface, such as mirror polishing (for transparent parts), VDI etching (such as leather texture, orange peel texture), or fire patterns.

Mold assembly (Fitting): Precisely assemble all parts into a complete set of molds to ensure that all moving components (sliders, inclined tops) operate smoothly and without error.

Stop 3: Trial Run & Process Optimization

This is a crucial step in verifying the mold and formulating the production process.

First mold trial (T0): Install the mold on the injection molding machine, conduct initial debugging with production materials, and produce the first batch of samples.

Sample evaluation and debugging

Dimensional measurement: Use equipment such as a three-coordinate measuring machine (CMM) and a two-dimensional image measuring instrument to inspect key dimensions.

Visual inspection: Check for defects such as material shortage, flash, shrinkage, air streaks, and silver streaks.

Functional testing: Conduct tests such as assembly and strength.

Process adjustment: Based on the sample issues, adjust parameters such as injection speed, pressure, temperature, and time (DOE experimental design method is often used for efficient process optimization).

Engineering Confirmation (EVT) & Parameter Locking: Submit samples to the customer for confirmation and make mold modifications and process optimizations based on feedback. The final optimized parameters are recorded in the injection molding process condition table as the mass production standard.

Stop 4: Mass Production & Process Control

The stage of ensuring stable, efficient and high-quality output.

Molding cycle: mold closing → injection → pressure holding → cooling → mold opening → ejection → part removal (automatically completed by the mechanical hand).

Statistical Process Control (SPC):

Key process parameter monitoring: Monitor and record injection time, peak injection pressure, material temperature, etc., to ensure process stability.

First Article Inspection (FAI): At the beginning of each shift or after mold change, a comprehensive inspection of the first product is conducted.

Round-trip inspection: Regularly conduct random checks on products (appearance, size).

Quality control chart: Use control charts such as X-R to monitor the stability of key product dimensions, detect abnormal trends in advance, and achieve preventive quality control.

Stop 5: Quality Assurance & Delivery

Full inspection and packaging: Conduct 100% visual inspection on the products or have them inspected through AOI (Automatic Optical Inspection) equipment, and then package them as required.

Outgoing Inspection (OQC): Conduct sampling inspections on batches about to be shipped to ensure they meet customer specifications.

Document delivery: Provide necessary quality documents along with the goods, such as the Shipment Inspection Report (OQC Report), Material Certification (COC), etc.

We are a plastic injection parts moulding manufacturer, providing high-quality plastic injection parts moulding manufacturing. As long as you want to customize/develop plastic injection parts moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.