- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Plastic injection pen moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize plastic injection pen moulding. We provide professional customized plastic injection pen moulding services, and we are a professional plastic injection pen moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing plastic injection pen moulding, our factory can provide one-stop service. We have design and production capabilities related to plastic injection pen moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized plastic injection pen moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For plastic injection pen moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

The injection molding process for plastic pens is a classic and highly efficient mass production process. Its core characteristics are high automation, multi-component coordination, and an uncompromising pursuit of aesthetic quality.

The injection molding process for plastic pens is a classic and highly efficient mass production process. Its core characteristics are high automation, multi-component coordination, and an uncompromising pursuit of aesthetic quality.

The following is a detailed description of the plastic pen injection molding process, specifically highlighting the unique characteristics of pens.

Complete Plastic Pen Injection Molding Process

A typical plastic pen typically consists of multiple components, including the barrel, cap, and refill cap. Each component requires its own mold and injection molding process. The entire process can be divided into three stages: component injection molding → assembly → packaging.

Stage 1: Component Injection Molding (Key Manufacturing Step)

This is the stage in which the individual plastic parts of the pen are manufactured. Although the pen's structure is simple, it places high demands on appearance (color, finish) and dimensions (especially for compatibility with the refill).

1. Material Preparation

Common Materials:

ABS: Commonly used for barrels and caps. It offers high strength, good toughness, and is easily dyeable. The surface can be electroplated or spray-coated.

Polystyrene (PS): Commonly used for transparent pen barrels (such as highlighters), it offers low cost and sufficient rigidity, but is relatively brittle.

Polypropylene (PP): Commonly used for refill caps or some movable parts, it offers excellent wear resistance and hinge properties (resists repeated bending).

Modified Materials: Masterbatches, fluorescent agents, and toughening agents are often added to the base material to meet specific color and functional requirements.

Material Processing: The material must be dried to remove moisture to prevent "silver streaks" or bubbles in the molded product.

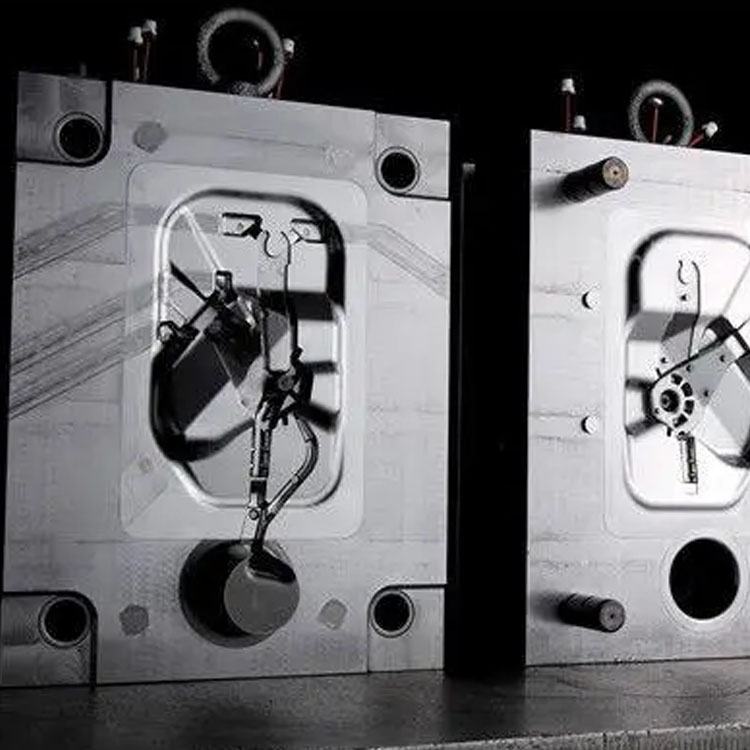

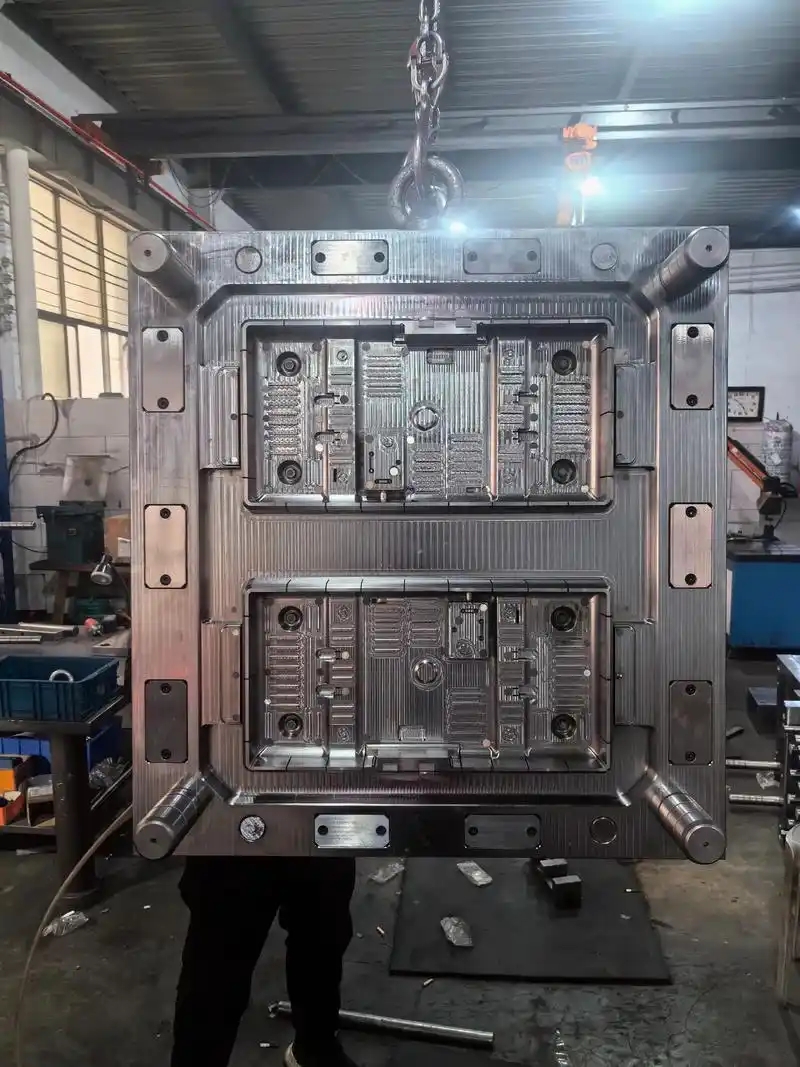

2. Mold Characteristics

Family Mold: Pen parts are small, so molds typically utilize a highly efficient design that can produce multiple or even dozens of parts from a single mold, greatly increasing production.

Hot Runner System: Standard configuration. This eliminates the need for sprue (sprue material), conserves raw materials, and enables fully automated production.

High-Finish Cavity: The cavity surface requires a mirror polish to ensure a smooth, glossy, and flawless surface.

Precision Ejection: Ejector pins are typically placed inside or hidden within the pen to ensure a flawless finish.

3. Injection Molding Process

Feeding and Drying: Plastic pellets are fed into a hopper via an automatic suction machine and dried.

Injection Molding: Molten plastic is injected into the mold cavity. The cycle time is extremely short, typically only a dozen to thirty seconds.

Drying and Cooling: After a brief holding period, the part cools and sets within the mold.

Mold Opening and Ejection: The mold opens, and the part is ejected by ejectors. A robot or automated device then removes it and places it in a bin or directly conveys it to the assembly line.

Second Stage: Assembly & Printing

After a brief rest period (for stress relief), the molded part enters the assembly stage.

Second Assembly:

Small metal parts such as the refill spring and nib may be assembled with the plastic parts to form the refill module.

The pen clip is snapped onto the pen cap.

Final Assembly:

The refill is installed into the pen barrel.

The pen cap is fitted onto the barrel.

The entire process is typically completed on an automated assembly line, including vibrating plate feeding, robotic gripping, and press assembly.

Surface Treatment/Printing:

Tampography: The most common process. Used to print brand logos, patterns, model numbers, etc. on the barrel. A soft silicone tip transfers ink from a pattern on a steel plate to the uneven surface of the barrel.

Painting: Applying color or a special feel to the barrel (e.g., rubberized paint).

Plating: Adding a metallic sheen (e.g., chrome or gold) to the cap or nib.

Stage 3: Quality Control & Packaging

Quality Control:

Appearance Inspection: Manual or machine vision inspection is used to check for scratches, shrinkage, color variations, and stains.

Functional Testing: Checks whether the pen writes smoothly, the clip is elastic, and the cap opens and closes smoothly.

Dimensional Inspection: Use tools such as calipers to check critical dimensions.

Packaging:

Automated packaging machines pack pens into blister packs or paper cards.

Packaging then proceeds to cartons and packaging for storage.

Core Flowchart:

Plastic granules + masterbatch → Drying → Melting in the injection molding machine → Injection into the mold → Cooling and molding → Robotic removal → (temporary storage) → Automated assembly → Pad printing of logo → Functional and appearance inspection → Blister packaging → Packing and storage

Unique Features of Pen Injection Molding:

Extreme Efficiency: Leveraging multi-cavity molds and hot runner technology, production efficiency is extremely high and costs are kept very low.

Appearance First: Surface defects (shrinkage, flash, air marks) are prohibited, and the molds require a mirror finish.

Highly Automated: From mold removal to assembly and packaging, the entire process requires virtually no human intervention, a typical application of a "dark factory."

Material Diversity: Flexible selection of different plastic materials is available based on the different parts and functions of the pens.

We are a plastic injection pen moulding manufacturer, providing high-quality plastic injection pen moulding manufacturing. As long as you want to customize/develop plastic injection pen moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

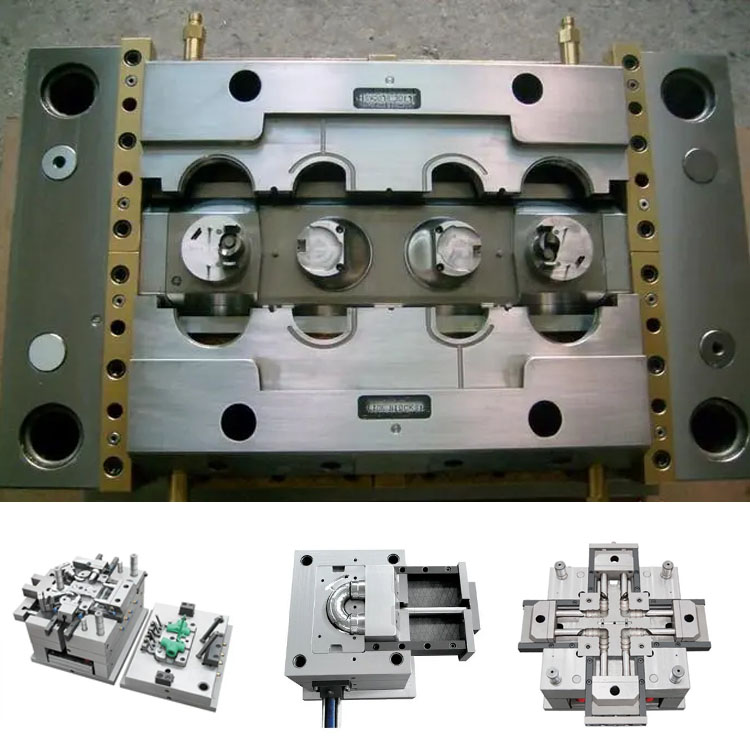

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

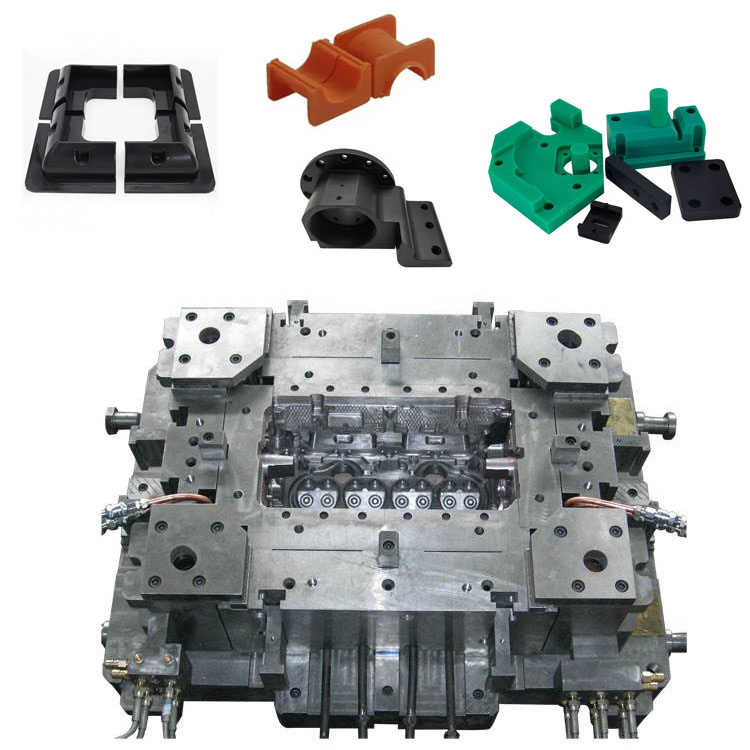

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

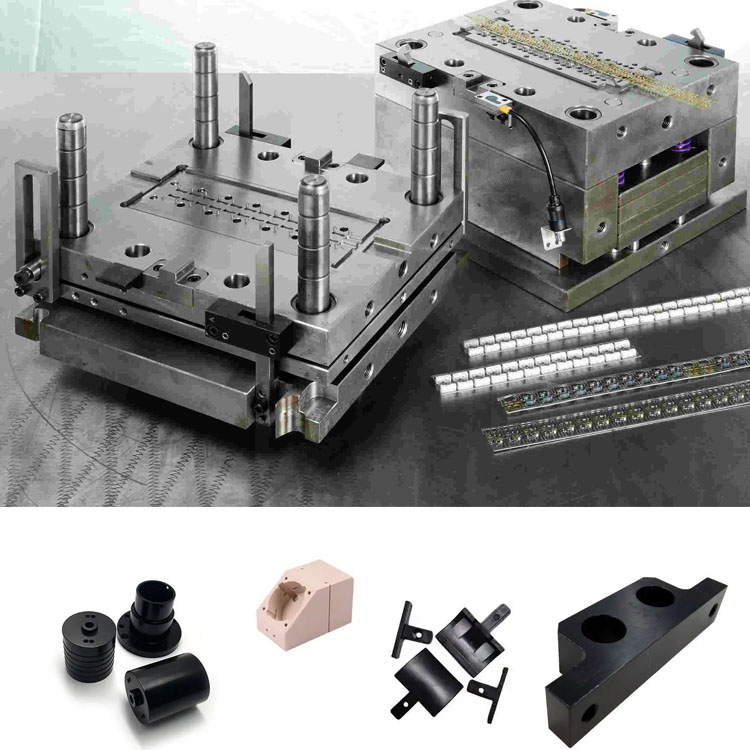

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.