- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

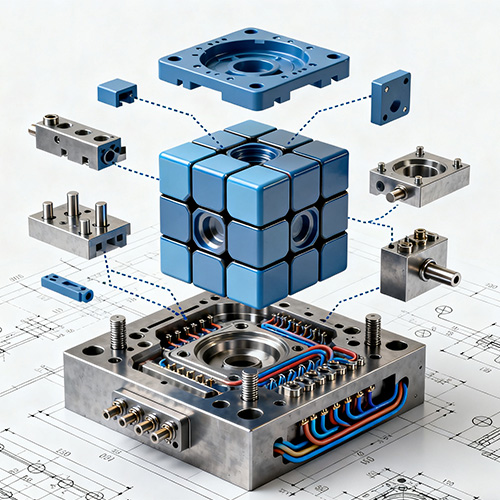

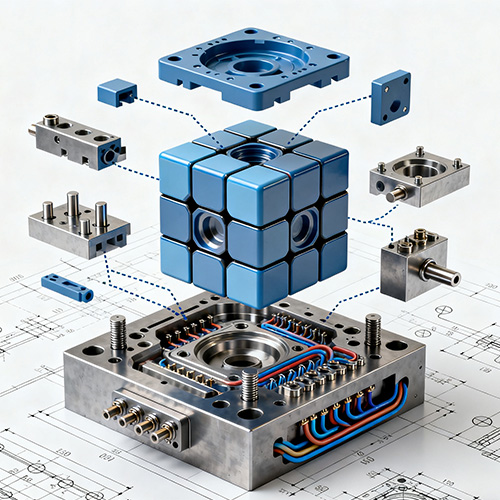

Plastic Rubik Cube Injection Moulding

For Plastic Rubik Cube Injection Moulding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

Send Inquiry

Plastic Rubik Cube Injection Moulding refers to a technology that produces core components of Rubik's cubes (such as cube blocks, central shaft sleeves, springs, positioning buckles) through customized injection molding processes, and finally assembles them into plastic Rubik's cubes that can rotate flexibly and have a restoration function. Its core feature is using the injection molding process to realize high-precision molding (dimensional tolerance within ±0.02mm) and structural adaptability of Rubik's cube components, ensuring smooth rotation of adjacent cube blocks (rotation resistance 50-100g) and precise positioning (misalignment deviation ≤0.1mm). Compared with traditional manual processing or 3D printing, Plastic Rubik Cube Injection Moulding can realize large-scale standardized production, balancing cost control and product consistency. It is widely used in toys, education, competitive sports and other fields, adapting to various Rubik's cube needs from entry-level to professional speed-solving levels.

P&M Plastic Rubik Cube Injection Moulding Introduction

A、Core Characteristics of Plastic Rubik Cube Injection Moulding

1. High-Precision Component Molding, Ensuring Smooth Rotation

Cube Block Molding: The side length tolerance of a cube Rubik's cube block must be controlled within ±0.01mm (e.g., for a standard 56mm Rubik's cube, the side length deviation ≤0.01mm), and the perpendicularity error of adjacent faces ≤0.05° to avoid jamming after assembly; the surface flatness of the block ≤0.02mm/m, ensuring tight fitting with adjacent blocks (gap ≤0.1mm) and no shaking during rotation;

Shaft Sleeves and Buckles: The inner hole diameter tolerance of the central shaft sleeve is ±0.005mm, and the fitting gap with the central shaft is 0.01-0.02mm, ensuring smooth rotation of the shaft sleeve around the shaft without jamming; the protrusion height tolerance of the positioning buckle is ±0.01mm, and the interference fit with the groove of the adjacent block is 0.02-0.03mm, realizing precise positioning and clear feedback during rotation (positioning feel error ≤10g).

2. Integrated Adaptation of Multiple Components, Simplifying Assembly Process

3. Precise Matching of Material Properties, Balancing Durability and Feel

B、Production Process of Plastic Rubik Cube Injection Moulding

1. Product Design and Mold Development

1) Product Design

Structural design: Draw a 3D model using CAD software (SolidWorks, UG), with a focus on designing the chamfer dimensions of the magic cube (R0.3-R0.5mm to reduce rotational lag), the step positioning of the central axis (ensuring that the coaxiality of the shaft sleeve is ≤ 0.01mm), and the guiding slope of the buckle (angle 15 ° -20 °, easy to assemble);

Simulation verification: Use CAE software (Moldflow) to simulate the injection filling process of Rubik's Cube blocks, optimize the wall thickness distribution (uniformly control within 1.5-2mm to avoid shrinkage marks); Verify the rotational resistance through motion simulation (set within the standard range of 50-100g), adjust the height of the positioning buckle to ensure consistent tactile sensation.

(2) Mold development

Mold material: The magic block mold is made of S136 stainless steel (with strong corrosion resistance and good polishing performance), and the shaft sleeve mold is made of H13 hot work mold steel (with good wear resistance and a service life of ≥ 500000 times);

Mold cavity design: The magic block mold cavity adopts mirror polishing (Ra ≤ 0.012 μ m) to ensure a smooth surface of the block; The multi cavity mold adopts a symmetrical layout (such as a circular distribution of 1 mold and 12 cavities) to ensure uniform filling of each cavity (filling time difference ≤ 0.5 seconds);

Cooling system: Arrange the water channels according to the thickness of the components (with a distance of 15-20mm between the water channels of the cube blocks and a cooling time of 15-20 seconds) to avoid dimensional deviations caused by uneven cooling; The shaft sleeve mold adopts conformal cooling to ensure the accuracy of the inner hole size (tolerance ± 0.005mm).

2. Raw Material Preparation and Injection Molding

(1) Raw material pretreatment

(2) Injection molding

3. Component Post-Processing and Assembly

(1) Post processing

(2) Assembly

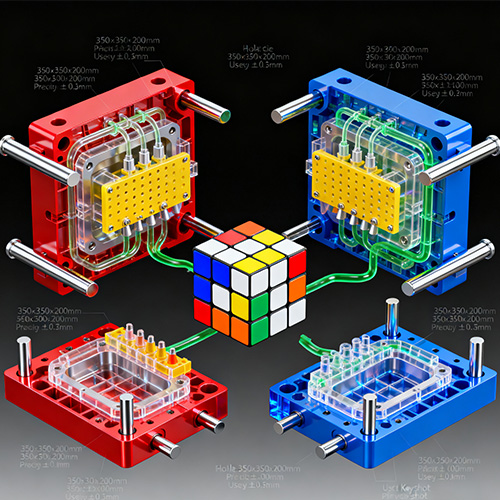

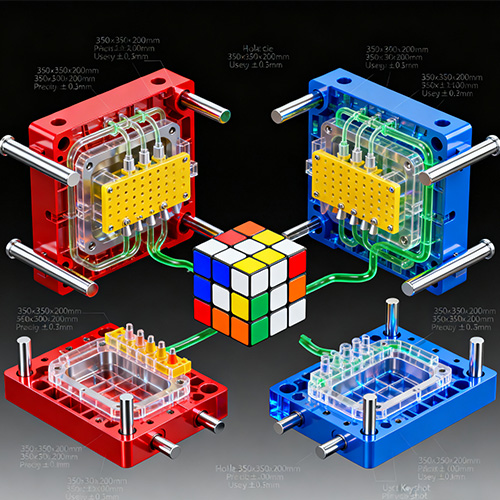

P&M Plastic Rubik Cube Injection Moulding(Specification)

|

Mould Name |

Plastic Rubik Cube Injection Moulding |

|

We promise |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

About 25 working days |

|

Product time |

7-15 Days |

|

Moud precision |

±0.1mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

Food grade plastic raw materials |

|

Origin |

Made in China |

P&M Plastic Rubik Cube Injection Moulding Feature And Application

1. Entry-Level Children's Rubik Cube

Core Requirements: High safety, low cost, easy operation, suitable for children aged 3-10.

Injection Molding and Material Features:

Cube blocks use ABS resin (low cost, good toughness, avoiding breakage when children drop it), and corners are rounded (R1.0-R1.5mm to prevent scratches);

Shaft sleeves and central shafts use ordinary POM (meeting basic smoothness requirements), and springs use elastic PP (low cost, elastic force 50-60g, suitable for children with small strength);

Molds adopt 24 cavities per mold (increasing output and reducing unit cost), and the surface is matte treated (avoiding strong light reflection to irritate children's eyes).

2. Professional Speed-Solving Rubik Cube

Core requirements: low rotational resistance, precise positioning, strong durability, suitable for racing athletes (10-30 years old), pursuing fast rotations of 5-10 times per second.

Injection molding and material characteristics:

The Rubik's Cube block is made of PC/ABS alloy (impact resistant, smooth surface, Ra ≤ 0.1 μ m, reducing rotational friction), with a uniform wall thickness controlled at 1.5mm (lightweight, overall weight ≤ 80g);

The shaft sleeve and central shaft are made of high wear-resistant POM (with 5% PTFE micro powder added, the friction coefficient is reduced to 0.15), combined with spring steel springs (elastic force of 80-100g, clear positioning feedback);

Using a needle valve hot runner mold (1 mold with 12 cavities to reduce the impact of gate residue on rotation), the component size tolerance is controlled within ± 0.005mm to ensure consistent rotation.

3. Educational and Customized Rubik Cube

Core requirements: Function integration (such as digital/graphic identification), personalized appearance, suitable for school teaching and corporate gift scenes.

Injection molding and material characteristics:

The Rubik's Cube block is made of PC/ABS alloy (with a surface that is easy to print and can add numbers, letters, or company logos through screen printing or water transfer printing);

Partial education Rubik's Cube integrated magnet positioning structure (pre embedded magnet slots in the cube block during injection molding, with an accuracy of ± 0.02mm to ensure magnet alignment);

The customized style adopts a dual color injection molding process (such as white body and red logo), and the mold design is a dual color mold (1 mold with 8 cavities), achieving personalized appearance and integrated functionality.

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Packing

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery.

The goods can be shipped by DHL , Fedex , UPS .

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days.

To Middle east countries takes about 18-25 days.

To European countries takes about 20-28 days.

To American countries takes about 28-35 days.

To Australia takes about 10-15 days.

To African countries takes about 30-35 days.

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1.Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould, Plastic Product, Metal Product, Dental Product, CNC machining.

4.Why should you buy from us not from other suppliers?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD, EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.