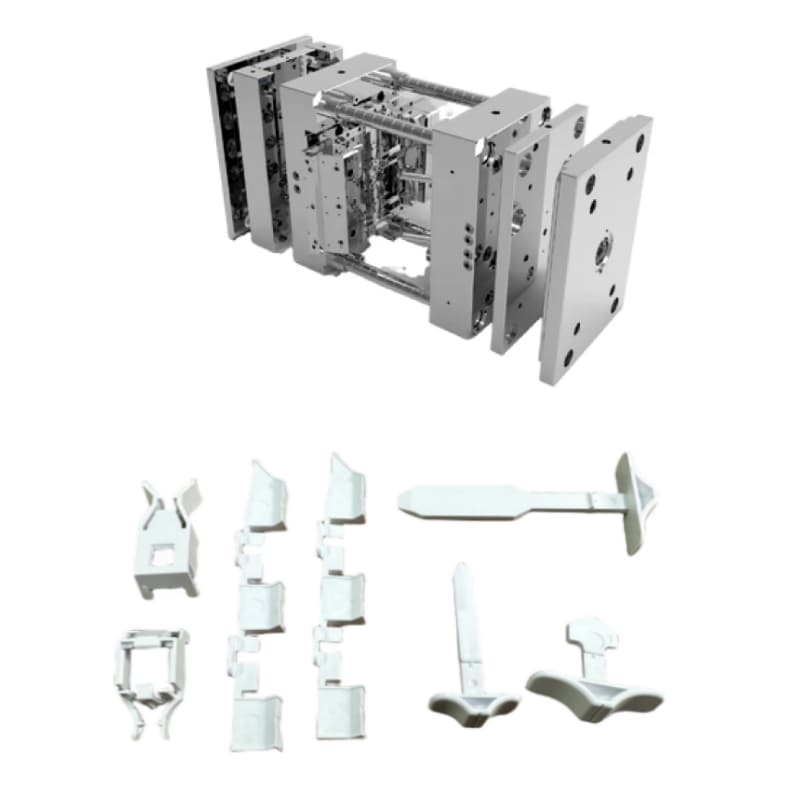

China Lifter Ejection System Molds Manufacturer, Supplier, Factory

We emphasize development and introduce new products into the market every year for Lifter Ejection System Molds, Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

Lifter Ejection System Molds, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

Hot Products

Baby Bottle Sterilizer Molding

With the increasing emphasis on the health of infants and young children, the market for baby bottle sterilizer molding is showing a thriving trend. Nowadays, the market for maternal and child products continues to expand, and consumers have increasingly high requirements for the safety and hygiene of baby products. Bottle sterilizer is an important tool for ensuring the safety of infant and toddler diet.Plastic Kids Dinner Plate Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Plastic Kids dinner plate molding. P&M are both a brand and a factory, with thousands of types of products, with high-quality service and quality as the first, Our main products is design and manufacturing of plastic mold, plastic product, metal product, We provide Plastic Kids dinner plate molding services. We have ISO 9001 certificates.Pencil Sharpener For Kids Molding

The children's pencil sharpener has rich and diverse functions, providing great convenience for children's learning. The automatic sharpening function is one of its most prominent features. Children only need to insert a pencil into the pencil sharpener and lightly press it, and the pencil sharpener can quickly sharpen the sharp tip of the pen. This not only greatly improves children's learning efficiency, but also eliminates the need for them to manually sharpen their pens.For more information on the Pencil Sharpener For Kids Molding, please feel free to contact us.Vision Improvement Equipment Moulding

As the professional manufacturer, we would like to provide you Vision Improvement Equipment Moulding. Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of custom Vision improvement equipment mould making technology. We provide professional custom mould services. We are a professional plastic mould manufacturer that can use injection moulding, blow moulding, die casting and rotational moulding. We have sufficient experience in product raw material selection and mould material selection. Pain massage equipment products have high requirements for the coordination between parts. Usually, the part structure of such products requires multiple mould sliders to assist in completion. We understand the advantages and disadvantages of part structure design and will provide customers with professional design suggestions.Plastic Sunglass Mold

Ningbo Plastic & Metal Products (P&M) is a distinguished plastic manufacturing facility located in Zhejiang Province, China, specializing in the production of top-of-the-line injection molds for plastic sunglass molds. With over 15 years of experience in the industry, we excel in the intricate art of designing and perfecting these molds.Plastic Beakers

Ningbo P&M specializes in the manufacturing of Plastic beakers and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic beaker solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic beakers sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic beakers. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.