China Mold for plastic cases Manufacturer, Supplier, Factory

The buyer pleasure is our primary concentrate on. We uphold a consistent level of professionalism, excellent, credibility and service for Mold for plastic cases, We are ready to cooperate with organization pals from at your home and abroad and make a great long term together.

Mold for plastic cases, For many years, we have now adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

Hot Products

Plastic Pet Toothbrush Molding

Ningbo (P&M) Plastic Hardware Products Co. boasts 15 years of expertise in crafting custom Plastic Pet Toothbrush Molding. We excel in professional mold customization services and are recognized as seasoned plastic mold manufacturers. Holding ISO 9001 certifications, we specialize in selecting optimal raw materials and mold materials. When crafting Plastic pet toothbrush, we prioritize material safety, utilizing food-grade plastics for utmost product hygiene. Proficient in material properties and mold design intricacies, we offer tailored material recommendations and expert design guidance to our clientele.Plastic Pet Water Bottle With Food Container Molding

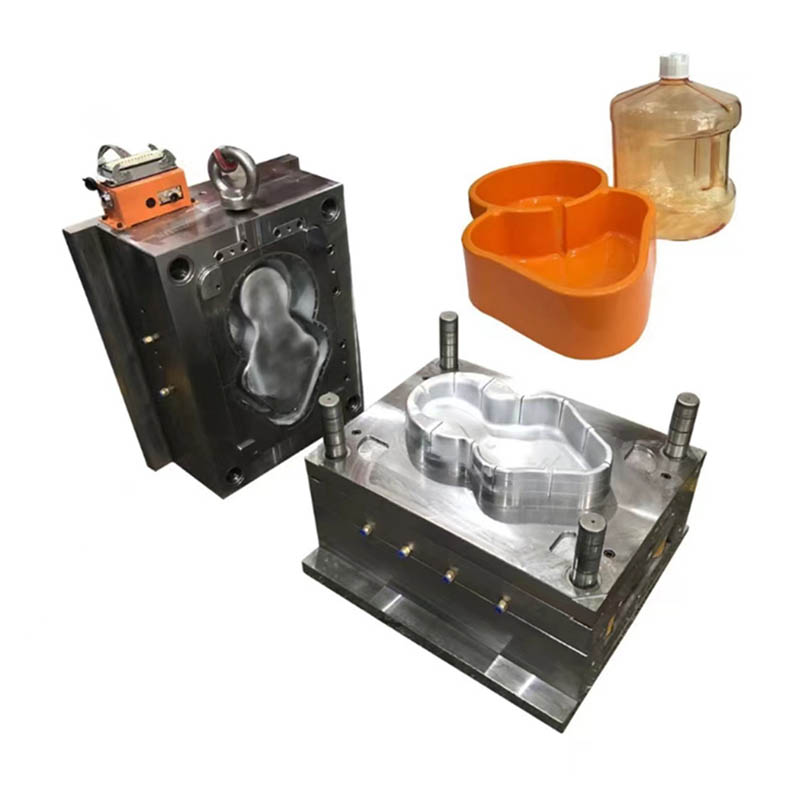

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Plastic pet water bottle with food container. We provide professional Plastic pet water bottle with food container molding service and we are professional Plastic pet water bottle with food container injection mold manufacturer. We have ISO 9001 certificates .Plastic Bath Mat Injection Mold

Ningbo Plastic & Metal Products (P&M) is a leading plastic manufacturing facility situated in Zhejiang Province, China. Specializing in the intricate craft of creating and refining Plastic bath mat injection molds, we boast over 15 years of industry expertise.Car Fender Mold

For car fender molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Car fender equipment includes: Front fender, rear fender, fender liner, fender extension, fender screws and fasteners.We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Blood Glucose Meter Moulding

For custom Blood glucose meter moulding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology. We provide professional custom mold services, and we are a professional plastic mold manufacturer. We can use injection molding, blow molding, die casting and rotational molding.Bike Parts Molding

As the professional manufacturer, we would like to provide you Bike Parts Molding. Injection molds are key tools for producing plastic parts for bicycles, from handlebar covers, seat cushions, mudguards, to various complex connectors and decorative parts, all of which cannot be separated from them. The quality of the mold directly determines the accuracy, strength, and appearance of the plastic parts. High precision molds can ensure the accuracy of component dimensions, making each part perfectly fit and improving the overall performance and stability of bicycles; Excellent mold making technology can endow components with better strength and durability, extending the service life of bicycles. The role of molds in shaping the appearance should not be underestimated. They can realize designers' creative ideas for bicycle shapes, from smooth lines to unique textures, adding unique beauty and personality to bicycles. It can be said that without advanced injection mold manufacturing technology, it is difficult to produce high-quality and diverse plastic parts for bicycles.