China POM (Acetal) plastic parts production Manufacturer, Supplier, Factory

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for POM (Acetal) plastic parts production, Our goods are strictly inspected before exporting , So we gain a excellent standing all around the planet. We wanting ahead to cooperation with you in the foreseeable future.

POM (Acetal) plastic parts production, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of ""human-oriented and faithful service"", with an aim to gain global recognition and sustainable development.

Hot Products

Sphygmomanometer Molding

For Customized sphygmomanometer molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 17 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding.Pacifier Brush Molding

The healthy growth of babies relies on clean and hygienic feeding tools, and pacifier brush molding plays a crucial role in their daily care. As a direct contact item for babies, the cleanliness of pacifiers directly affects their health. If the pacifier is not thoroughly cleaned, residual milk stains can breed bacteria and pose potential health risks to the baby.Car Roof Molding

For car roof molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Car roof equipment includes: Roof luggage rack, sunroof cover, antenna base cover, roof spoiler, roof wiper cover, roof antenna cover, roof windshield chrome strip, roof rail cover.We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Digital Abacus Game Toys Molding

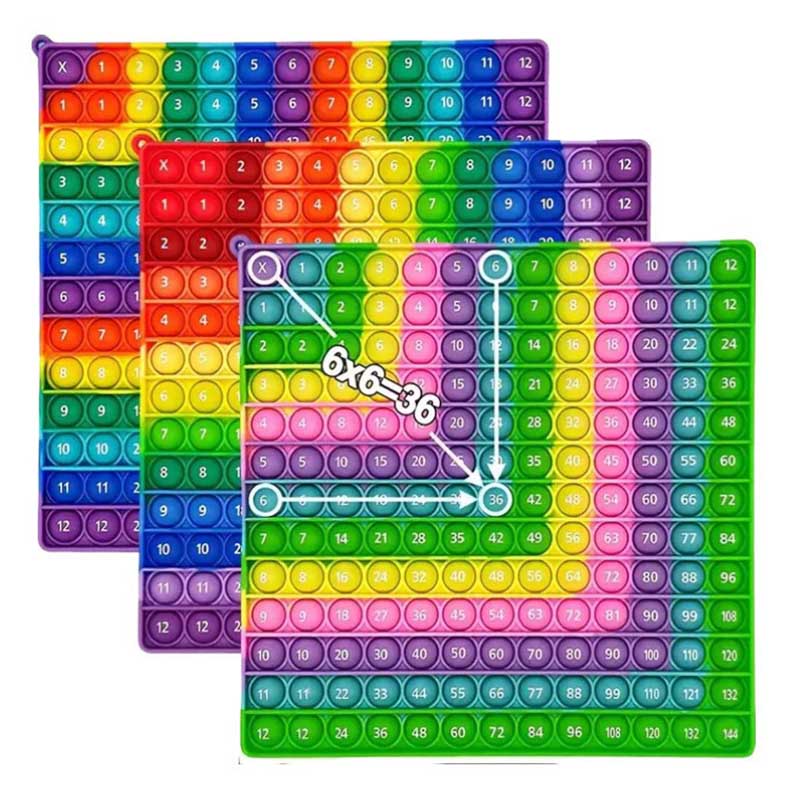

Digital abacus game toys occupy an important position in the children's toy market due to their unique puzzle solving ability. For children, digital abacus game toys can not only help them recognize numbers and learn simple calculations, but also exercise their hand eye coordination and logical thinking abilities. For more information on the Digital Abacus Game Toys Molding, please feel free to contact us.Bike Parts Molding

As the professional manufacturer, we would like to provide you Bike Parts Molding. Injection molds are key tools for producing plastic parts for bicycles, from handlebar covers, seat cushions, mudguards, to various complex connectors and decorative parts, all of which cannot be separated from them. The quality of the mold directly determines the accuracy, strength, and appearance of the plastic parts. High precision molds can ensure the accuracy of component dimensions, making each part perfectly fit and improving the overall performance and stability of bicycles; Excellent mold making technology can endow components with better strength and durability, extending the service life of bicycles. The role of molds in shaping the appearance should not be underestimated. They can realize designers' creative ideas for bicycle shapes, from smooth lines to unique textures, adding unique beauty and personality to bicycles. It can be said that without advanced injection mold manufacturing technology, it is difficult to produce high-quality and diverse plastic parts for bicycles.Skateboard Molding

The main function of skateboard molding is to inject molten plastic raw materials into specific mold cavities, cool and solidify them, and shape them into the skateboard surface we see. This process may seem simple, but it actually requires high-precision mold design and manufacturing processes. The quality of the mold directly affects the quality and performance of the skateboard, from the flatness and curvature of the board surface to the strength and durability of the skateboard, all of which are closely related to injection molds.