China Sanitary Ware Plastic Molds Manufacturer, Supplier, Factory

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Sanitary Ware Plastic Molds, We never stop improving our technique and high quality to maintain up with the enhancement trend of this industry and fulfill your pleasure effectively. For anyone who is fascinated within our solutions, you should get in touch with us freely.

Sanitary Ware Plastic Molds, So far our solutions have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We've 13years specialist sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality merchandise and excellent service.

Hot Products

Plastic Pet Comb Molding

Ningbo (P&M) Plastic Hardware Products Co. boasts 15 years of expertise in crafting custom Plastic pet comb molding. We excel in professional mold customization services and are recognized as seasoned plastic injection molding manufacturers. Holding ISO 9001 certifications, we specialize in selecting optimal raw materials and mold materials. Our Plastic pet comb molding is specially designed for grooming tools for cats, dogs and other pets. Made of high quality plastic material, it is lightweight and durable, not easy to damage pet skin and hair. The comb is well-designed and can effectively remove pet hair knots, promote blood circulation and keep pet hair smooth and silky. Suitable for all hair lengths and types of pets, all large and small dogs, cats and other pets, especially suitable for long-haired pets or pets prone to knots. We customize your own comb to match you and your pet.Plastic Pet Water Bottle With Food Container Molding

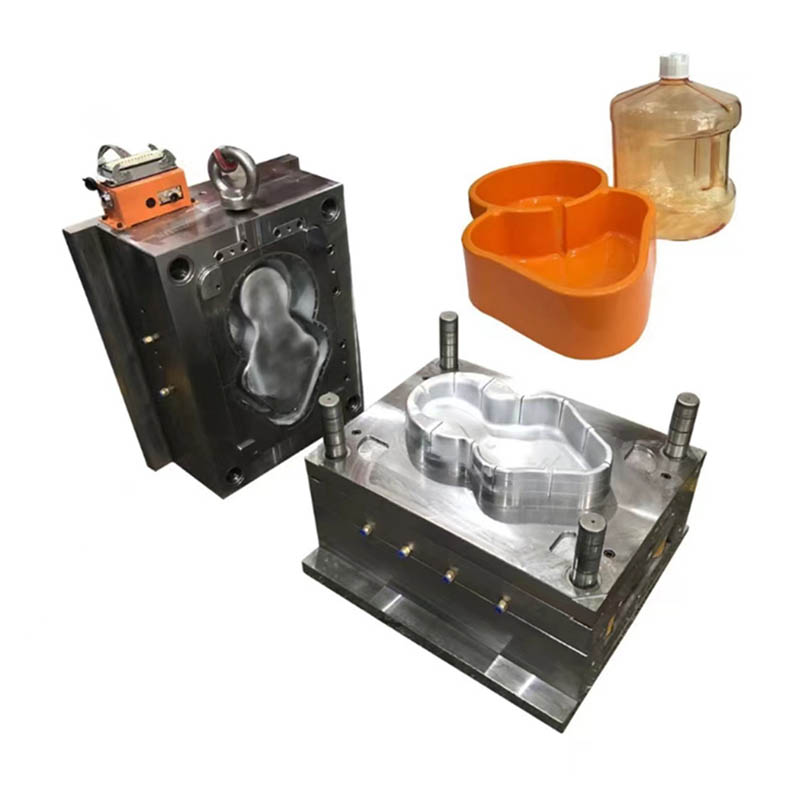

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Plastic pet water bottle with food container. We provide professional Plastic pet water bottle with food container molding service and we are professional Plastic pet water bottle with food container injection mold manufacturer. We have ISO 9001 certificates .Plastic Couplings Molding

Ningbo P&M specializes in the manufacturing of Plastic couplings molding and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic couplings solutions. Being a specialized manufacturer, we comprehend the distinct demands of the Plastic couplings sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic couplings. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.Plastic Scraper Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Plastic scraper molding. P&M are both a brand and a factory, with thousands of types of products, with high-quality service and quality as the first, Our main products is design and manufacturing of plastic mold, plastic product, metal product, We are a manufacturer providing Plastic scraper molding services. We have ISO 9001 certificates ,We have enough experience in product raw material selection and mold material selection.Plastic Measuring Cups Set Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for plastic measuring cups set molding. P&M are both a brand and a factory, with thousands of types of products, with high-quality service and quality as the first, Our main products is design and manufacturing of plastic mold, plastic product, metal product, We provide Plastic measuring cups set molding services. We have ISO 9001 certificates ,We have enough experience in product raw material selection and mold material selection. In terms of raw material selection, Custom plastic water cups are usually made of food-grade plastic materials, such as polyethylene (PE), polypropylene (PP), etc. to ensure safety and reliability.90% plastic water cups of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production.Electric Toy Molding

With the initial development of the plastic industry, injection molding technology has begun to be applied in the field of toy manufacturing. At this stage, injection molds are relatively simple, and the toys produced are mainly in a relatively simple shape and color, mainly to meet the basic play needs of children. Consumers' demand for toys is constantly increasing. During this period, injection molding technology continued to improve, and the precision of mold manufacturing significantly increased. The electric toy molding industry has experienced rapid development, producing toys with richer and more diverse shapes, brighter colors, and greatly improved quality.