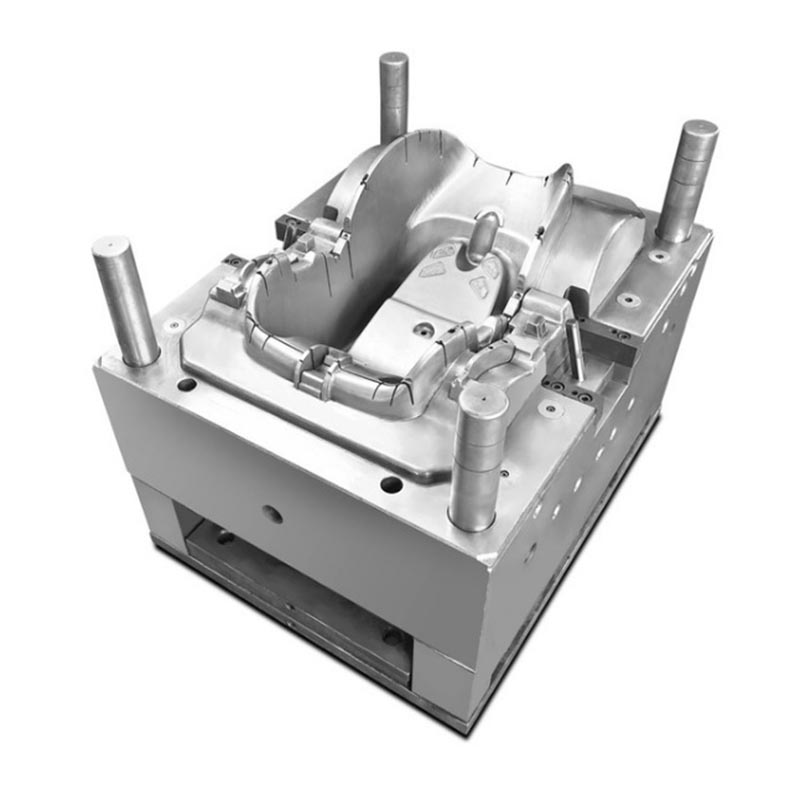

China Structural Part Injection Molds Manufacturer, Supplier, Factory

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for Structural Part Injection Molds, We often concertrating on creating new creative solution to meet request from our customers everywhere in the planet. Sign up for us and let's make driving safer and funnier with each other!

Structural Part Injection Molds, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Hot Products

Trolley Storage Rack Molding

This is P&M from China, P&M is a supplier of plastic injection molding, we would like to provide you with custom trolley storage rack molding service. We custom trolley storage rack mould, also help you making the other storage products. We provide you high-quality mold manufacturing mold services also the on-time transportation services. P&M is a mold manufacturing factory and a plastic product manufacturing factory, providing customers with one-stop services. Our factory has been in operation for over 15 years. we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding.Pet Plastic Cups Plastic Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized pet plastic cups. We provide professional custom mold service and we are professional Pet Plastic Cups Plastic Molding manufacturer. We have ISO 9001 certificates We have enough experience in product raw material selection and mold material selection. Pet plastic cups requires a higher level of material safety. Usually We use food-grade plastics to ensure safe and hygienic products. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.Multifunctional Therapeutic Instrument Moulding

P&M has 17 years of Multifunctional therapeutic instrument Moulding technology. We provide professional mold customization services. We are a professional plastic mold manufacturer. We can use injection molding, blow molding, die casting and rotational molding.Plastic Elbows Molding

Ningbo P&M specializes in the manufacturing of Plastic elbows molding and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic elbow solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic elbows sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic elbows. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.Round Shape Acrylic Jewelry Box Mold

Ningbo Plastic & Metal Products (P&M) is a distinguished plastic manufacturing facility situated in Zhejiang Province, China, specializing in crafting top-of-the-line injection molds for Round Shape Acrylic Jewelry Box Molds. With a wealth of experience exceeding 15 years in the industry, we have mastered the art of intricately designing and perfecting these molds.Musical Toy Molding

Musical Toy Molding, in simple terms, are specialized molds used for producing various types of music toys. The production process of music toys such as our common sound button music box and music flashing module cannot be separated from the key tool of injection molding. Its working principle is to heat plastic raw materials to a molten state, and then apply a certain pressure using an injection molding machine to inject the molten plastic into the mold cavity.