- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Small plastic parts specialist

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Custom Injection molded parts. We have ISO 9001 certificates. We provide professional Custom Small plastic parts and we are professional Small plastic parts specialist. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.

Send Inquiry

We are a dedicated small plastic parts specialist, delivering precision custom miniature plastic components and optional assembly solutions to clients across electronics, medical devices, automotive, robotics, and consumer goods sectors. Unlike finished product traders, we focus exclusively on the design and injection molding of small-scale plastic parts (0.1mm–50mm in size)—leveraging specialized micro-molding technology to meet the unique precision, miniaturization, and functionality requirements of your applications. Our core strength lies in translating complex small-part needs into high-quality solutions: from micro-gears for wearable devices to tiny medical connectors—ensuring every small plastic part offers consistent performance, dimensional accuracy, and seamless integration with your end products.

Custom Small Plastic Parts: Structural Design & Material Matching

Our expertise as a small plastic parts specialist is rooted in precision structural customization for miniaturized components, where even minute design details impact performance. Our engineering team collaborates closely with you to design small parts tailored to your installation space, load, and functional demands: For micro-electronic components (e.g., connector pins, sensor housings), we optimize thin-wall structures (0.1–1mm) with ultra-tight tolerances (±0.003mm) and precision mounting features; For small mechanical parts (e.g., micro-gears, tiny bearings), we refine tooth profiles, shaft diameters, and sliding surfaces to ensure smooth operation in compact spaces; For medical micro-parts (e.g., catheter components, surgical tool tips), we create crevice-free, biocompatible structures with micro-scale channels or openings; For automotive small parts (e.g., sensor pins, interior trim clips), we design lightweight, vibration-resistant structures that fit tight assemblies. Key custom structural features for small plastic parts: micro-scale precision features (e.g., 0.05mm diameter holes), reinforced micro-hubs (for shaft connection), snap-fit micro-interfaces (for tool-free assembly), and integrated micro-markings (for traceability). Every design undergoes micro-FEA simulation and prototype validation to ensure structural integrity and functionality.

Material selection is critical for small plastic parts, and as a specialist, we offer tailored material solutions optimized for miniaturization, strength, and application-specific demands. Small parts often require materials with excellent flowability (to fill tiny mold cavities) and dimensional stability (to maintain precision). Our material expertise covers a range of high-performance plastics suitable for small-scale molding: For general-purpose small electronic parts: ABS, PP, and PC (selected for good flowability and surface finish); For high-precision micro-parts: LCP (Liquid Crystal Polymer) and POM (Acetal) (offer exceptional dimensional stability and wear resistance); For medical small parts: FDA-approved PP, PEEK, and TPE (biocompatible, sterilizable, and suitable for micro-molding); For high-temperature small automotive parts: Heat-stabilized PPS and PEI (withstand 120–200°C in compact under-hood spaces); For lightweight small consumer parts: Modified PP and TPU (lightweight, flexible, and cost-effective). We also test material flowability and shrinkage rates specifically for small-part molding to avoid defects like short shots or warpage.

Key Plastic Materials for Small Parts & Their Applications

As a small plastic parts specialist, we leverage materials that excel in miniaturized molding and small-part performance. Below are our proven material solutions, tailored to specific small-part applications:

- LCP (Liquid Crystal Polymer): Ideal for high-precision micro-electronic parts (e.g., connector pins, micro-sensor housings). Offers exceptional dimensional stability (tolerance ±0.003mm), high flowability (critical for filling tiny mold cavities), and heat resistance (up to 260°C). Suitable for small parts requiring ultra-precision and compatibility with surface mount technology (SMT).

- POM (Acetal Copolymer): For small mechanical parts (e.g., micro-gears, tiny sliding components). Provides low friction coefficient (0.15), excellent wear resistance, and consistent dimensional stability (shrinkage rate ≤1%). Ideal for small parts with moving interfaces, ensuring smooth operation and long service life.

- Medical-Grade PP: For small medical components (e.g., catheter tips, syringe parts). FDA-approved, biocompatible, and easy to micro-mold. Offers good chemical resistance (suitable for sterilization) and cost-effectiveness, making it a top choice for disposable and reusable medical small parts.

- PC (Polycarbonate): For small high-impact parts (e.g., small electronic device casings, automotive sensor covers). Delivers exceptional impact resistance (20kJ/m²) and transparency (90% light transmittance) in miniaturized form. Operating temperature range: -40°C to 130°C, suitable for small parts in harsh environments.

- TPU (Thermoplastic Polyurethane): For small flexible parts (e.g., tiny gaskets, wearable device components). Flexible (Shore A 30–70), kink-resistant, and offers good adhesion to rigid plastics. Ideal for small parts requiring sealing, cushioning, or ergonomic flexibility.

Small Plastic Parts Molding Process: Specialist Features & Advantages

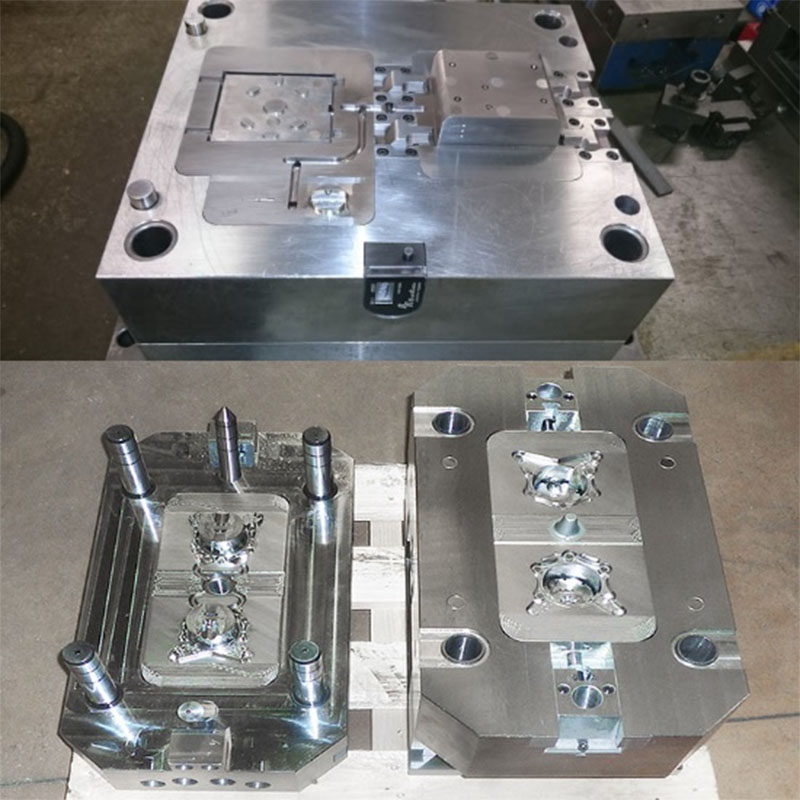

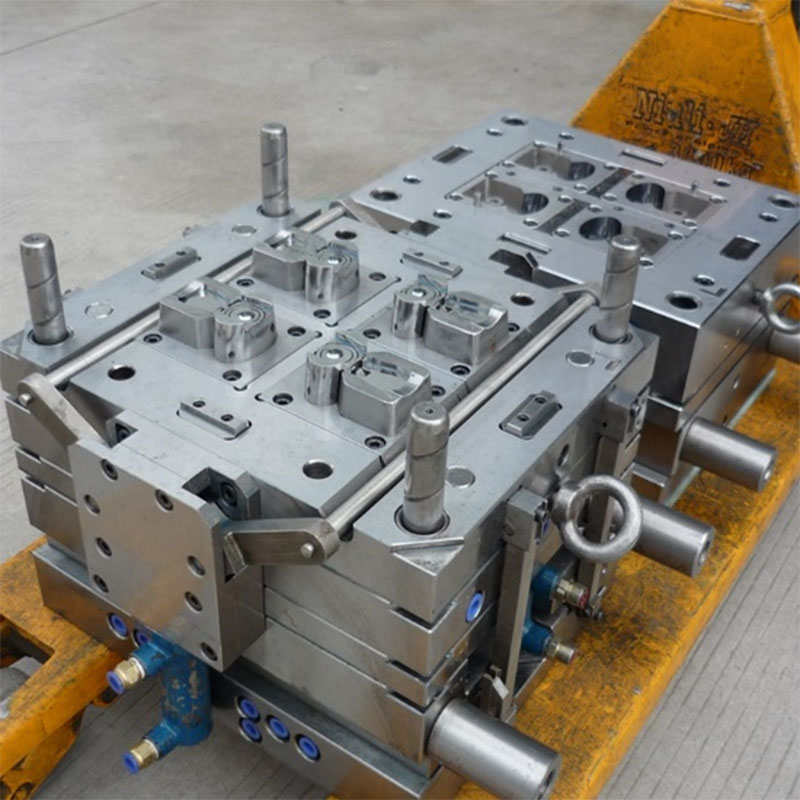

Our molding process as a small plastic parts specialist is engineered for micro-precision and consistency, leveraging specialized equipment and techniques to master the challenges of small-part production. Key process features include:Specialized micro-injection molding machines (5–50 tons clamping force) with high-precision screw and barrel systems for accurate material metering (±0.01g); Miniature mold engineering—hardened steel molds with CNC-machined micro-cavities (tolerance ±0.002mm), equipped with precision cooling systems to avoid warpage; Automated micro-handling—robotic systems with vision guidance to handle small parts without damage, ensuring consistent part transfer; In-line micro-inspection—100% dimensional testing via 3D micro-scanning, visual inspection with high-magnification cameras, and functional testing (e.g., micro-gear meshing, connector fit). We support both small-batch (50–1,000 units) prototyping and high-volume (100k+ units) production with multi-cavity micro-molds for cost efficiency.

The advantages of choosing us as your small plastic parts specialist include: Ultra-precision capability—tolerances as tight as ±0.003mm, ensuring small parts fit and function perfectly in compact assemblies; Miniaturization expertise—ability to mold complex small parts with micro-scale features (e.g., 0.05mm holes, 0.1mm ribs) that general molders cannot achieve;Consistent quality—strict process control and micro-inspection reduce defect rates to ≤0.1%, ensuring reliable supply; Design flexibility—ability to customize small parts in various shapes, sizes, and colors to match your exact requirements; Cost efficiency—specialized multi-cavity micro-molds and automated processes lower per-unit costs for high-volume small-part production.

Value-Added Assembly for Small Plastic Parts

To complement our small plastic parts specialist service, we offer custom micro-assembly solutions—integrating small plastic components into ready-to-install sub-assemblies. Small parts require delicate handling and precise alignment, and our assembly team uses specialized micro-fixtures and vision-guided systems to ensure accuracy. Examples include: assembling micro-gears with shafts and motors for wearable devices, integrating small medical connectors with tubing (sterile assembly in ISO 7 cleanrooms), and kitting small electronic components (connectors, pins) with hardware for automotive applications. We also offer post-molding value-added services for small parts: micro-deburring, surface coating, and laser marking—ensuring the final sub-assembly meets your exact functional and aesthetic requirements.

As your trusted small plastic parts specialist, we prioritize understanding your unique miniaturization needs—from ultra-precision tolerances to application-specific material demands. Whether you need micro-electronic components, tiny medical parts, or small mechanical components, our expertise ensures every small plastic part is engineered for optimal performance and seamless integration. Contact us today to discuss your small plastic part project and experience the difference of working with a specialized partner.

We are plastic mold maker and can provide custom mold service, we can make injection molds, blow molds, rotational molds and die-casting molds.

For custom injection molds, we can provide professional custom injection molding services. Usually Plastic injection mold manufacturing Molding are manufactured using injection molding technology. The mold materials for injection molds can be chosen from P20, 718, S136, H13 and so on. The mold material reflects the mold life and product material requirements.

For parts that require blow molding production, we can also provide professional custom blow molding services.

|

Product Name |

Small plastic parts specialist

|

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic injection mold manufacturing Injection Mould making

1.We communicate product design according to samples/drawings and your requirements.

2.After the product design is confirmed, we carry out the mold design, we provide all kinds of injection molds, blow molds, silicone molds, die-casting molds services.

3.Material procurement, steel cutting and mold basic tools.

4.Mold assembly

5.Mold inspection, tracking and controlling mold processing.

6. We will inform you the date of mold trial and send you the sample inspection report and injection parameters together with the sample.

7.Your instruction and confirmation of shipment.

8.Prepare the mold before packing.

Plastic injection mold manufacturing molding Specification

1. Professional manufacturer, design, production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Transaction process:

Mold testing:

Once the mold is complete, I do a mold test. It usually takes about 3-5 days to complete. We need to assemble the mold, adjust the pressure data of the machine, and try production. We need to check whether there are problems during the normal production of the mold and make modifications.

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

Factory

Video-1: (Factory Video)

Video-2: (Injection Molding)

Video-3: (Blow molding)

Video-4: (Blow molding)

Video-5: (Roll molding)

Customer satisfaction is our most important goal. We focus on communication and cooperation with our customers, always pay attention to their needs and provide quick response and quality customer service. Our injection production mold factory is committed to establishing long-term relationships and ensuring that our customers receive the best after-sales service during the purchase and use of our products, and we will definitely do our best to solve any problems for our customers.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us?

Mould,Plastic Product, Metal Product,Dental Product,CNC machining.

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6. What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.