- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

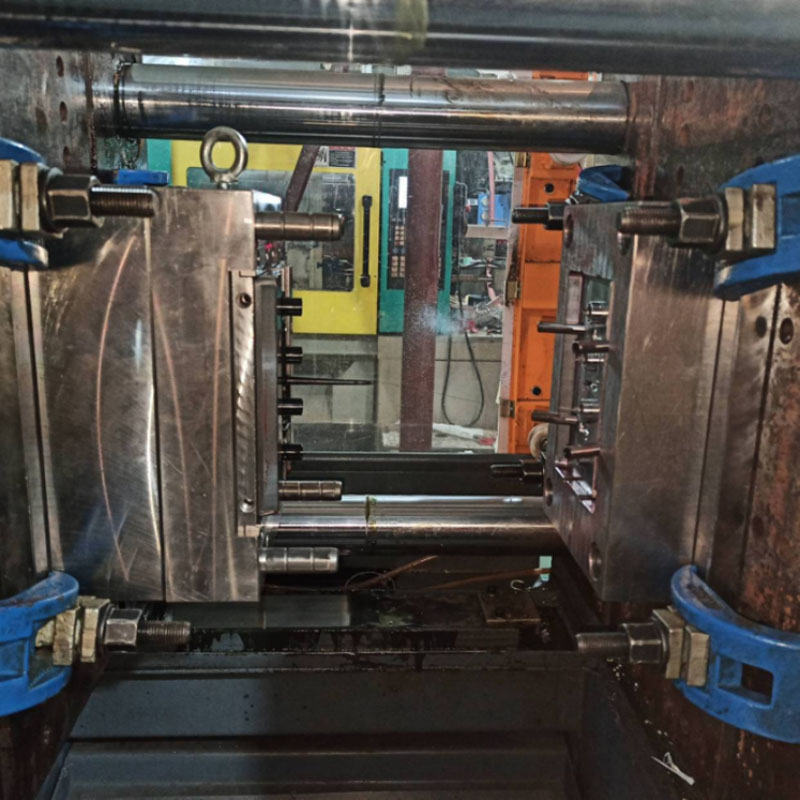

Sofa-leg-injection-moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize sofa-leg-injection-moulding. We provide professional customized sofa-leg-injection-moulding services, and we are a professional sofa-leg-injection-moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing sofa-leg-injection-moulding, our factory can provide one-stop service. We have design and production capabilities related to sofa-leg-injection-moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.

Send Inquiry

In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized sofa-leg-injection-moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For sofa-leg-injection-moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

Systematic technical analysis of sofa leg injection molding (updated in 2025), combined with structural load-bearing requirements, appearance requirements and cost control, from material selection to process innovation, it is summarized into five core modules:

I. Material selection and enhanced design

1. High-load-bearing substrate formula

Main material:

Glass fiber reinforced PP (GF30%): flexural strength > 85MPa, optimal cost (¥15/kg)

Engineering plastic solution: PA66+GF35% (flexural modulus > 10,000MPa), used for high-end sofas

Anti-scratch modification: Add 2% silicone micropowder (particle size 5μm), wear resistance increased by 40% (ISO 9352 test)

2. Key points of structural enhancement

Metal insert embedding:

Threaded steel sleeve (ISO 4017 standard) preheated to 120℃

Coating thickness ≥ 3mm (anti-crack design)

graph TB

A[main load-bearing column] --> B[radial reinforcement ribs]

B --> C[rib height = wall thickness 150%]

C --> D[demolding angle 1.5-2°]

II. Core strategy of mold design

1. Heavy-duty mold strengthening solution

Mold frame, LKM 5050 standard + reinforcement plate, rigidity increased by 30%

Ejection system, Ø20mm nitrided ejector pin (H-type layout), ejection force > 8 tons

Cooling system, 3D conformal water channel + beryllium copper insert, temperature difference ≤±3℃

2. Special surface treatment

Decorative surface: etched + hard chrome plating (Ra 0.05μm, HV1000)

Anti-slip bottom surface: spark pattern + nano-hydrophobic coating (contact angle > 110°)

III. Precise control of injection molding process

Process window and limit parameters

Melt temperature, 220-250℃ (PP), >270℃ degradation, infrared real-time monitoring + PID compensation

Injection pressure, 100-130MPa, <90MPa underfilling, multi-stage injection (3-speed variable speed)

Press holding pressure, 70-90MPa, >100MPa flash, closed loop of in-mold pressure sensor

Cooling time, wall thickness × 2.0s/mm, shortening deformation ↑ by 15%, pulsating cooling technology

Mold temperature, 60-80℃ (front mold), >85℃ mold sticking, dual-mold temperature machine partition control

Innovative process application:

Micro-foaming enhancement: supercritical N₂ injection (pressure 25MPa), 20% weight reduction and elimination of shrinkage marks (for non-visible areas).

In-mold assembly: metal connectors and plastics are molded synchronously, with positioning accuracy of ±0.1mm (saving post-process costs).

IV. Defect prevention and reliability assurance

1. Solutions to common problems

Stress cracking:

Pressure holding curve slow down (slope ≤ 5MPa/s)

Mold temperature is stepped down from 90℃ to 50℃ (to eliminate internal stress)

Load deformation:

R angle at the root of the reinforcement ≥ 1.5mm (stress concentration is reduced by 60%)

Add 0.5% carbon nanotubes (bending modulus ↑ 25%)

2. Extreme test standards (better than national standard QB/T 1952.1)

Static load test: >200kg load for 24h, deformation ≤1mm

Fatigue test: 100,000 times 5° swing test (amplitude ±50N)

V. Cutting-edge technologies for cost reduction and efficiency improvement (2025)

AI dynamic compensation system

Real-time monitoring of glass fiber orientation (ultrasonic sensor), automatic adjustment of flow channel balance, mechanical fluctuation ↓40%

High-value application of recycled materials

Recycled PP after reaction expansion (MAH-g-PP) + glass fiber regeneration, strength recovery rate >90% (cost ↓25%)

Topology optimization manufacturing

Lightweight design based on force simulation (weight reduction of 30%)

# Core logic of topology optimization

def topology_optimization(load_map):

return density_filter(sensitivity_analysis(load_map), min_thickness=3mm)

Technical iron law: Sofa leg injection molding must follow the **"mechanics first, cost controllable, appearance up to standard" triangle rule**:

Strength formula: wall thickness × glass fiber content ≥ 6.0 (empirical coefficient)

Economic red line: unit cost ≤ 5% of the total sofa price

Process restricted area: melt retention time > glass fiber length degradation threshold (≤ 4min when L/D = 25)

2025 trend: smart piezoelectric material injection molding (adding 0.3% BaTiO₃), realizing footstep vibration energy collection, empowering smart furniture.

sofa-leg-injection-moulding

We are a sofa-leg-injection-moulding manufacturer, providing high-quality sofa-leg-injection-moulding manufacturing. As long as you want to customize/develop sofa-leg-injection-moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Shaver Moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.