- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Stackable plastic storage tool parts bin storages moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize stackable plastic storage tool parts bin storages moulding. We provide professional customized stackable plastic storage tool parts bin storages moulding services, and we are a professional stackable plastic storage tool parts bin storages moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials.

Send Inquiry

In the process of customizing stackable plastic storage tool parts bin storages moulding, our factory can provide one-stop service. We have design and production capabilities related to stackable plastic storage tool parts bin storages moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies. In addition, our company has established cooperative relationships with plastic raw material suppliers, printing manufacturers, etc. to ensure the supply of raw materials and printing quality. Through our rich experience and perfect supply chain, our company can provide customers with high-quality customized stackable plastic storage tool parts bin storages moulding products to meet their specific needs. At the same time, we have 10 years of professional foreign trade service experience, understand the foreign trade process, and better serve our customers. For stackable plastic storage tool parts bin storages moulding products, we can make corresponding plastic parts, which is mainly done through injection molds.

The injection molding process of stackable plastic storage tool parts boxes is a process with extremely high requirements for structural design, dimensional accuracy, strength and durability. The core lies in achieving smooth stacking functionality, excellent compressive strength and convenient handling experience.

The following is the detailed professional process for injection molding of this type of product.

The entire injection molding process of stackable plastic storage boxes

Phase One: Product Design and Material Selection - The Foundation of Functionality

Design determines the core user experience of a product.

Key structural design

Stacked clips and guiding structures: This is the soul of the design. The clips at the bottom of the upper box and the edge at the top of the lower box must fit precisely to achieve stable stacking, easy alignment, and easy separation. It is usually designed with guiding bevels.

Reinforcement rib layout: The side and bottom of the box must be designed with dense grid-shaped reinforcement ribs to achieve the maximum compressive and impact strength with the least material consumption, ensuring that the bottom box does not deform after stacking several layers.

Handle design: The handle should be ergonomically designed to ensure a comfortable grip and a sturdy structure.

Uniform wall thickness: The main body wall thickness is usually 2.5-3.5mm, and the thickness of the reinforcing ribs is about 50%-60% of the main body wall thickness to prevent shrinkage marks on the back.

Material selection

Polypropylene (PP) : The absolute preferred material.

Reasons: Low cost, excellent toughness (resistant to drops and impacts), good fatigue resistance (the box lid is not easy to break when opened and closed repeatedly), low density (the product is lightweight). Usually, copolymer PP or grades with toughening agents added are used.

ABS: If higher requirements are placed on surface hardness, rigidity and gloss, ABS can be chosen, but it is more expensive and has inferior low-temperature impact resistance compared to PP.

Additive: Usually color masterbatch is added. For outdoor use or occasions where UV resistance is required, UV stabilizers must be added to prevent aging and brittleness.

Phase Two: Mold Design and Manufacturing - Ensuring Precision and Efficiency

Storage box molds are typical large molds.

Large mold bases and processing: Due to the large size of the product, large mold bases need to be used, and gantry CNC is adopted for mold core processing.

Hot Runner system: Essential. Adopt multi-point hot nozzles (such as four or six points) for glue injection to balance the filling of huge cavities, reduce flow length and internal stress, and save raw materials.

Cooling system: Crucial. It is necessary to design efficient and uniform cooling waterways, especially in areas with dense reinforcing ribs, to prevent product warping and deformation due to uneven cooling, which may affect the stacking function.

Exhaust system: Sufficient exhaust slots must be provided at the final filling point of the melt to prevent trapped gas from causing charring (brown streaks appear on the product surface) or incomplete filling.

Slider mechanism: It is used to handle lateral inverted structures such as handle holes and clips.

Ejection system: A large number of evenly distributed ejector pins or push plates are required to provide a smooth and balanced ejection force and prevent the box from deforming.

Phase Three: Injection Molding Process - Controlling deformation and shrinkage

The core of process calibration is to ensure dimensional stability and prevent warping.

Material treatment: PP has weak water absorption, but it is recommended to dry it at 80℃ for 1-2 hours to ensure the best surface quality.

Injection molding machine: Injection molding machines that require large tonnage (usually over 500 tons) and large injection volume.

Core process

Mold temperature: It is recommended that the mold temperature be controlled at 40-60℃. Moderate mold temperature helps to reduce internal stress and prevent deformation.

Injection speed: Medium speed injection is adopted. If it is too fast, it is easy to generate high internal stress; if it is too slow, it may cause the filling end to cool too quickly.

Holding pressure and duration: This is the key to controlling shrinkage (depression). A lower but longer holding pressure should be applied to slowly replenish and shrink, especially at the junction of the reinforcing ribs and the main body wall, to prevent shrinkage marks. Insufficient pressure holding is the main reason for the decline in the strength of the box body.

Cooling time: It must be sufficient to ensure that the product is fully cooled and set before being ejected to prevent deformation.

Phase Four: Post-processing and Quality Inspection - Final verification of functionality

Post-processing

Gate removal: When the mechanical hand automatically picks up the piece, separate or manually trim the main runner solidified material.

** rigorous quality inspection ** :

Dimensional inspection: Use large calipers and 3D measuring instruments to inspect the length, width, height, and diagonal dimensions of the box body, as well as the key fit dimensions of the stacking clips, to ensure smooth stacking.

Visual inspection: Check for defects such as shrinkage, flash, material shortage, charring, and color difference.

Functional Testing (Core)

Stacking test: Stack multiple boxes to the specified height (such as 5 layers), and after 24 hours, check whether the bottom boxes have irrecoverable deformation and whether the clips are still valid.

Drop test: A box filled with weights is freely dropped from a certain height (such as 1 meter) to test whether its impact resistance performance breaks.

Static load test: Apply a pressure far greater than the rated load on the box cover to test its bending resistance and the strength of the hinges.

Handle strength test: Test the load-bearing capacity and fatigue resistance of the handle.

We are a stackable plastic storage tool parts bin storages moulding manufacturer, providing high-quality stackable plastic storage tool parts bin storages moulding manufacturing. As long as you want to customize/develop stackable plastic storage tool parts bin storages moulding products, you can find us. We have professional injection mold design and mature manufacturing technology, providing you with one-stop service, from product design-mold making-product production-product packaging-product transportation, we can help you in every link. As long as you come to us, we will provide you with the ultimate service and satisfy you in terms of product quality, production time, information dialogue, etc.

|

Product Name |

Treadmill moulding |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

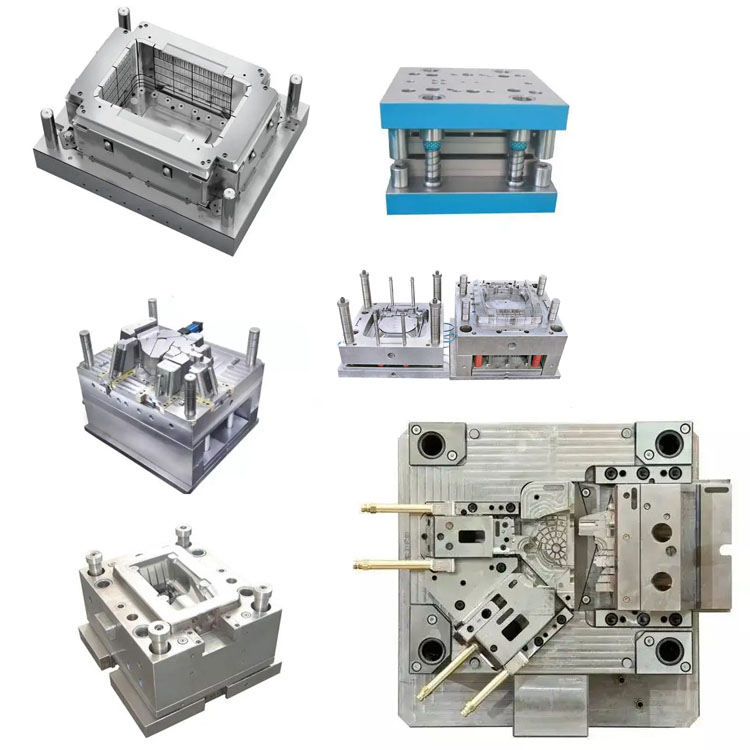

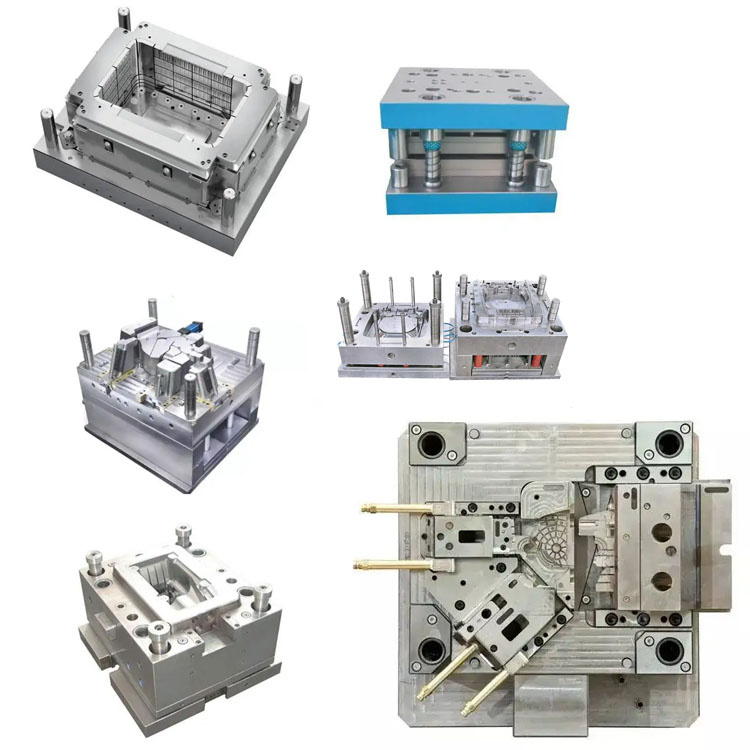

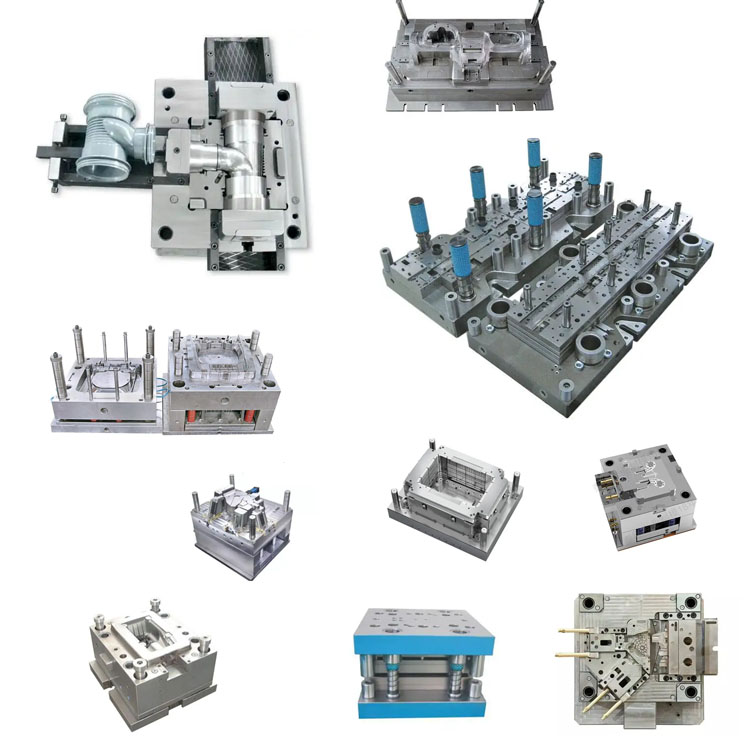

Plastic Injection Mould making

Plastic molding specifications

Mold design:

Transaction process:

Mold testing:

Product packaging

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 17 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.