China Exceptional Plastic Injection Tooling Manufacturer, Supplier, Factory

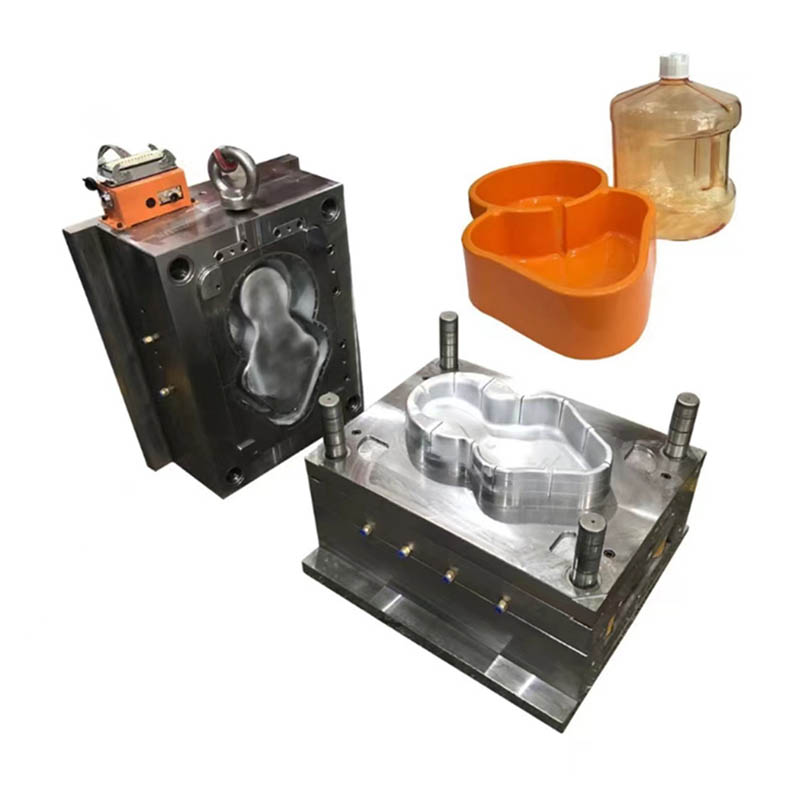

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Exceptional Plastic Injection Tooling, We goal at Ongoing system innovation, management innovation, elite innovation and sector innovation, give full play for the overall advantages, and constantly make improvements to support excellent.

Exceptional Plastic Injection Tooling, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we present, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and comprehensive parameters and any other info weil be sent for you timely for your inquiries. So make sure you make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We have been confident that we are intending to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

Hot Products

Car Threshold Bar Equipment Molding

For customized car threshold bar equipment molding , NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Car threshold bar equipment includes: plastic shell, connecting parts, decorative strips, lighting devices, light lens etc. We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Plastic Caps Molding

Ningbo P&M specializes in the manufacturing of Plastic caps molding and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic cap solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic caps sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic caps. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.Plastic Seals Molding

Ningbo P&M specializes in the manufacturing of Plastic seals molding and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic seal solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic seals sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic seals. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.Trafficc Toy Molding

High Quality Trafficc Toy Molding Manufacturer.Manufacturers of injection molds for transportation toys have strict processes and requirements in terms of manufacturing technology.When designing injection molds, the first step is to conduct a feasibility analysis of the plastic molding process. This includes evaluating the dimensions, precision, structure, and other aspects of the product to determine its suitability for injection molding. For example, it is necessary to consider whether the wall thickness of the plastic part is uniform, whether there is a demolding slope, and whether the design of reinforcing ribs and rounded corners is reasonable.Plastic Pipe Supports

Ningbo P&M specializes in the manufacturing of Plastic pipe supports and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic pipe support solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic pipe supports sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic pipe supports. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.Plastic Centrifuge Tubes

Ningbo P&M specializes in the manufacturing of Plastic centrifuge tubes and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic centrifuge tube solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic centrifuge tubes sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic centrifuge tubes. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.