China Micro Injection Mold Tooling Manufacturer, Supplier, Factory

Our organization puts emphasis to the administration, the introduction of talented personnel, and also the construction of team building, making an attempt hard to enhance the standard and liability consciousness of workers members. Our business successfully attained IS9001 Certification and European CE Certification of Micro Injection Mold Tooling, Initial enterprise, we understand each other. Additional enterprise, the trust is getting there. Our firm usually at your service anytime.

Micro Injection Mold Tooling, With good quality, reasonable price and sincere service, we enjoy a good reputation. Items are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

Hot Products

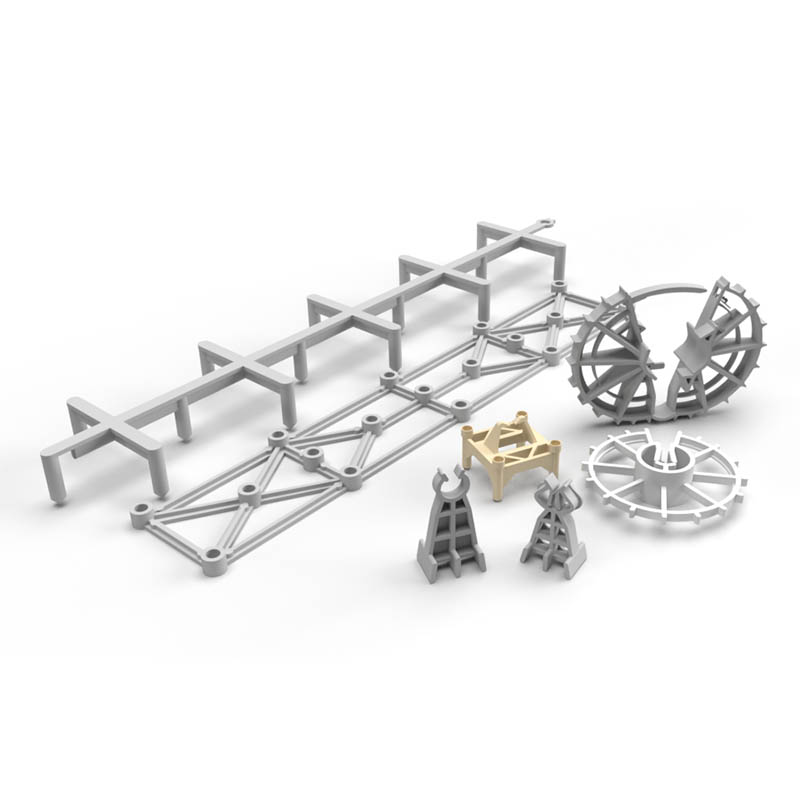

Transport Cage Accessories Molding

Ningbo (P&M) Plastic and Metal Products Co., Ltd. has 15 years of mold manufacturing technology and can customize transport cage accessories molding. We provide professional customized mold services and are a professional transport cage accessories molding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. The products of transportation cage equipment require relatively high coordination between parts. Usually, the part structure of these products requires multiple mold sliders to assist in completion. We are aware of the advantages and disadvantages of component structure design, and we will provide professional design suggestions to our customers.Children's Pencil Case Molding

Children's stationery box mold manufacturers play a crucial role in the stationery industry. Manufacturers of Children's Pencil Case Molding have continuously innovated and improved product quality to meet the diverse demands of the market for stationery boxes. They not only provide high-quality molds for stationery production enterprises, but also promote the development of the entire stationery industry. In market competition, they occupy an important position with their professional technology, high-quality services, and efficient production capacity.Car Roof Molding

For car roof molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Car roof equipment includes: Roof luggage rack, sunroof cover, antenna base cover, roof spoiler, roof wiper cover, roof antenna cover, roof windshield chrome strip, roof rail cover.We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Plastic Supports Molding

Ningbo P&M specializes in the manufacturing of Plastic supports molding and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic support solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic supports sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic supports. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.Plastic Jewelry Bags Mold

Ningbo Plastic & Metal Products (P&M) is a distinguished plastic manufacturing facility situated in Zhejiang Province, China, specializing in the production of top-of-the-line injection molds for Plastic Jewelry Bags Mold. With a wealth of experience exceeding 15 years in the industry, we have honed our skills in the intricate art of designing and perfecting these molds.Plastic Cleaning And Hygiene Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Plastic Cleaning and hygiene molding. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection.